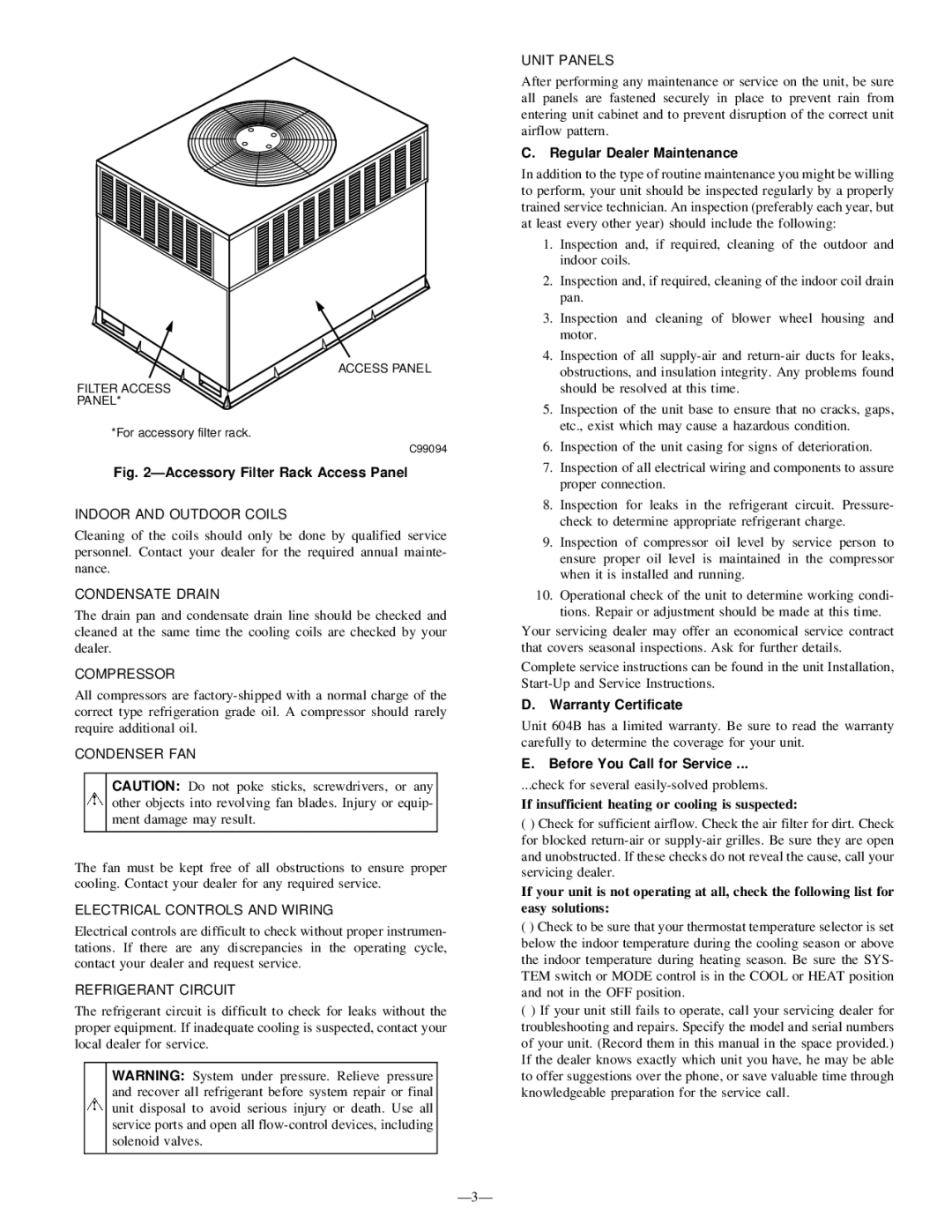

ACCESS PANEL

FILTER ACCESS

PANEL*

*For accessory filter rack.

C99094

Fig. 2ÐAccessory Filter Rack Access Panel

INDOOR AND OUTDOOR COILS

Cleaning of the coils should only be done by qualified service personnel. Contact your dealer for the required annual mainte- nance.

CONDENSATE DRAIN

The drain pan and condensate drain line should be checked and cleaned at the same time the cooling coils are checked by your dealer.

COMPRESSOR

All compressors are

CONDENSER FAN

CAUTION: Do not poke sticks, screwdrivers, or any other objects into revolving fan blades. Injury or equip- ment damage may result.

The fan must be kept free of all obstructions to ensure proper cooling. Contact your dealer for any required service.

ELECTRICAL CONTROLS AND WIRING

Electrical controls are difficult to check without proper instrumen- tations. If there are any discrepancies in the operating cycle, contact your dealer and request service.

REFRIGERANT CIRCUIT

The refrigerant circuit is difficult to check for leaks without the proper equipment. If inadequate cooling is suspected, contact your local dealer for service.

WARNING: System under pressure. Relieve pressure and recover all refrigerant before system repair or final unit disposal to avoid serious injury or death. Use all service ports and open all

UNIT PANELS

After performing any maintenance or service on the unit, be sure all panels are fastened securely in place to prevent rain from entering unit cabinet and to prevent disruption of the correct unit airflow pattern.

C.Regular Dealer Maintenance

In addition to the type of routine maintenance you might be willing to perform, your unit should be inspected regularly by a properly trained service technician. An inspection (preferably each year, but at least every other year) should include the following:

1.Inspection and, if required, cleaning of the outdoor and indoor coils.

2.Inspection and, if required, cleaning of the indoor coil drain pan.

3.Inspection and cleaning of blower wheel housing and motor.

4.Inspection of all

5.Inspection of the unit base to ensure that no cracks, gaps, etc., exist which may cause a hazardous condition.

6.Inspection of the unit casing for signs of deterioration.

7.Inspection of all electrical wiring and components to assure proper connection.

8.Inspection for leaks in the refrigerant circuit. Pressure- check to determine appropriate refrigerant charge.

9.Inspection of compressor oil level by service person to ensure proper oil level is maintained in the compressor when it is installed and running.

10.Operational check of the unit to determine working condi- tions. Repair or adjustment should be made at this time.

Your servicing dealer may offer an economical service contract that covers seasonal inspections. Ask for further details.

Complete service instructions can be found in the unit Installation,

D.Warranty Certificate

Unit 604B has a limited warranty. Be sure to read the warranty carefully to determine the coverage for your unit.

E.Before You Call for Service ...

...check for several

If insufficient heating or cooling is suspected:

( ) Check for sufficient airflow. Check the air filter for dirt. Check for blocked

If your unit is not operating at all, check the following list for easy solutions:

( ) Check to be sure that your thermostat temperature selector is set below the indoor temperature during the cooling season or above the indoor temperature during heating season. Be sure the SYS- TEM switch or MODE control is in the COOL or HEAT position and not in the OFF position.

( ) If your unit still fails to operate, call your servicing dealer for troubleshooting and repairs. Specify the model and serial numbers of your unit. (Record them in this manual in the space provided.) If the dealer knows exactly which unit you have, he may be able to offer suggestions over the phone, or save valuable time through knowledgeable preparation for the service call.

Ð3Ð