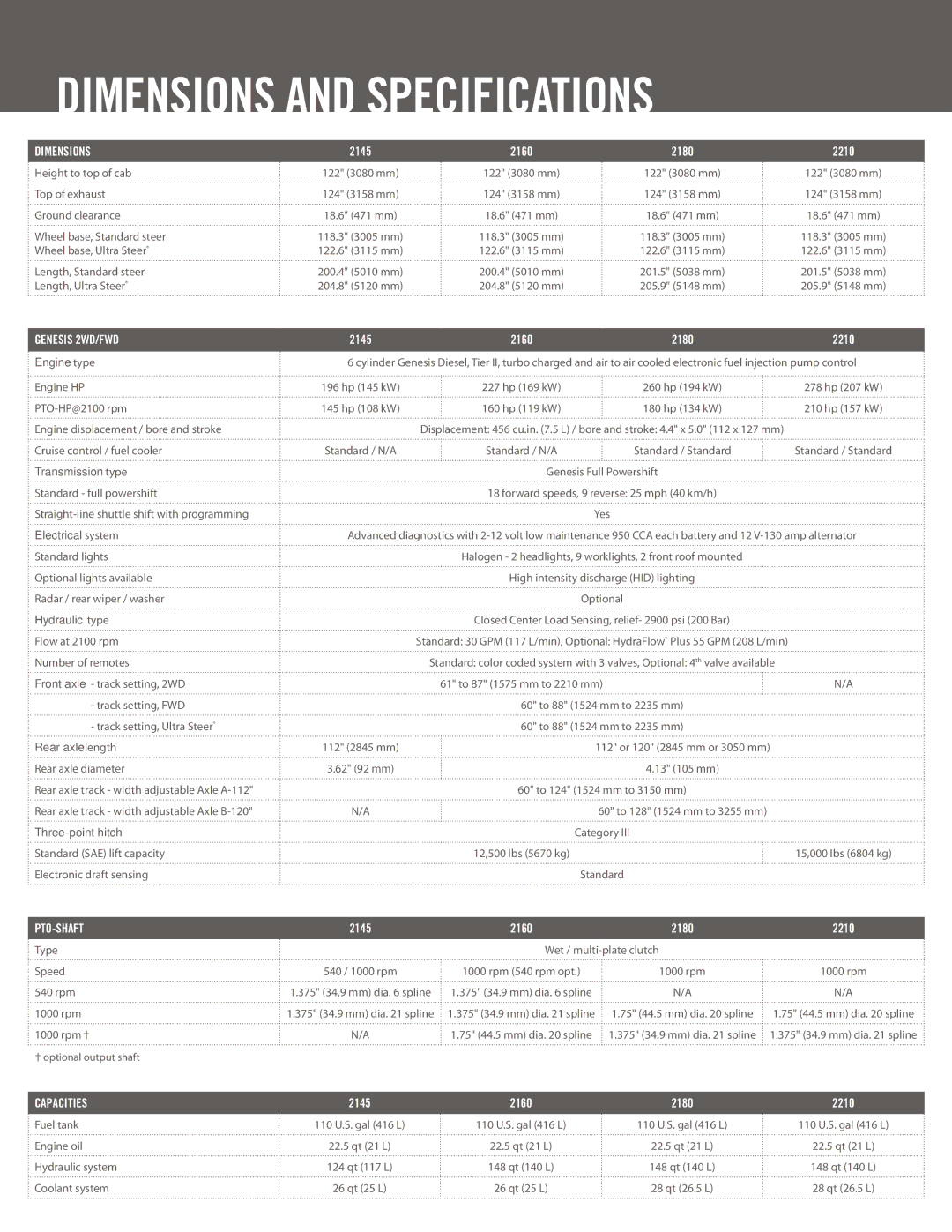

2160, 2210, 2145, 2180 specifications

Bühler is a renowned name in the agricultural and food processing machinery industry, particularly known for its cutting-edge technologies in grain handling and processing equipment. Among its most popular models are the Buhler 2180, 2145, 2210, and 2160. These models showcase a blend of innovation, efficiency, and reliability, tailored to meet the diverse demands of modern farming operations.The Buhler 2180 is a versatile machine known for its robust construction and high-output capabilities. One of its most remarkable features is its advanced processing technology which ensures optimal grain quality. The 2180 is equipped with an efficient cleaning system that removes impurities and ensures that the grains are sorted accurately. Its user-friendly interface allows for easy operation and monitoring, making it suitable for both experienced operators and newcomers alike.

The Buhler 2145, on the other hand, is engineered for medium-sized operations. It combines powerful performance with energy efficiency, making it a cost-effective solution. This model boasts an intelligent control system that enables precision in grain processing. The 2145 is also designed with safety features that comply with international standards, ensuring a secure working environment.

Moving on to the Buhler 2210, this model stands out for its impressive throughput capacity. It is designed to handle large volumes of grain while maintaining high quality standards. The 2210 includes state-of-the-art aeration and drying technologies, which are crucial for preserving the integrity of the grain during processing. Additionally, its modular design allows for easy upgrades and modifications according to the evolving needs of the users.

Lastly, the Buhler 2160 is particularly noted for its compact size, making it an excellent choice for operations with space constraints. Despite its smaller footprint, the 2160 does not compromise on performance. It incorporates advanced diagnostic features that facilitate maintenance and reduce downtime. Its build quality ensures durability, capable of withstanding rigorous environmental conditions associated with agricultural processing.

In summary, the Buhler 2180, 2145, 2210, and 2160 are exemplary models that highlight Bühler's commitment to innovation and quality in grain handling technology. Each model is tailored to meet specific operational needs, offering various features that enhance productivity, safety, and efficiency. As agricultural demands continue to evolve, Bühler’s machinery remains at the forefront of technological advancement in the industry.