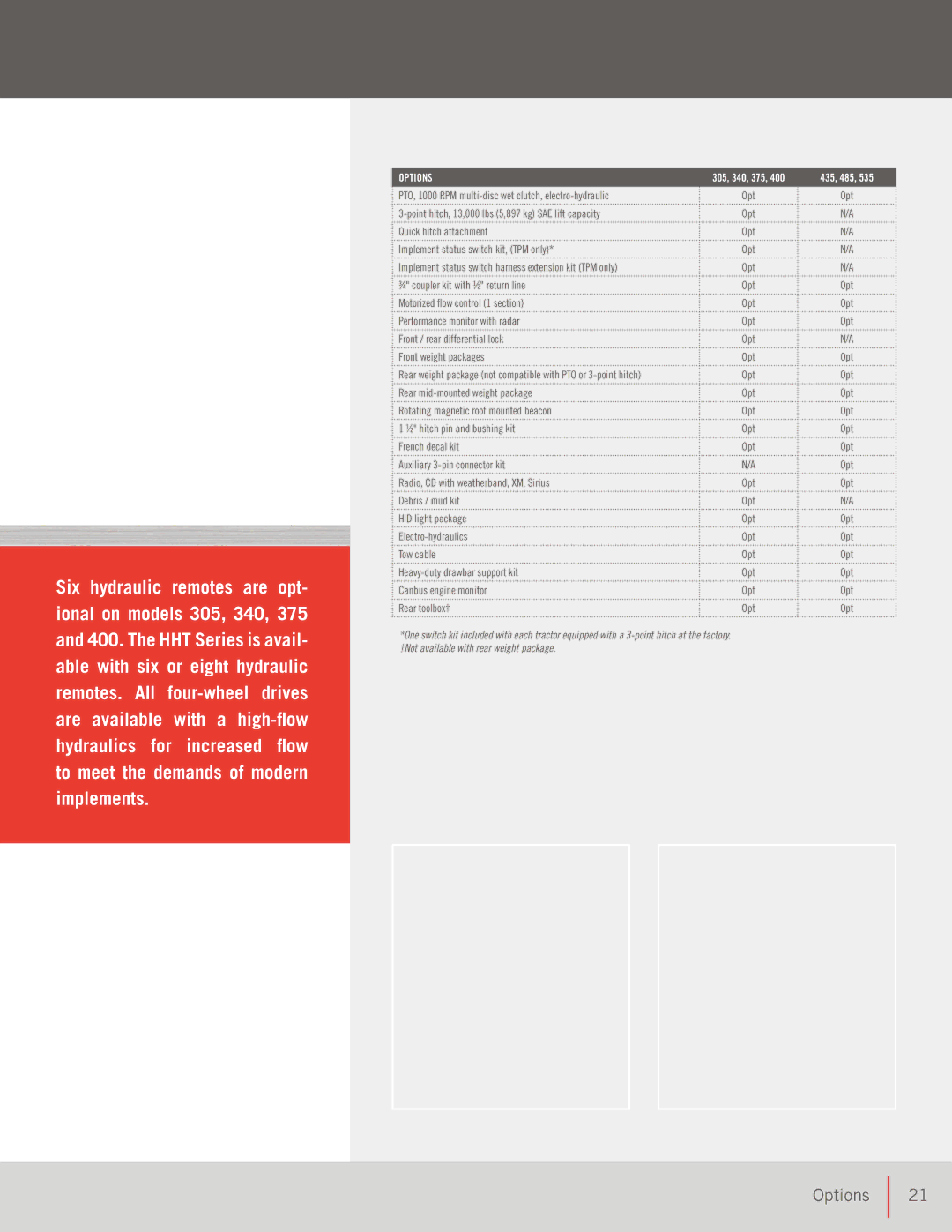

305, 340, 375, 400 specifications

Bühler is a prominent name in the field of food processing and technology, well-regarded for its innovative solutions and high-quality machinery. The Buhler 400, 375, 340, and 305 models embody the company's commitment to advanced engineering and efficiency in grain milling and processing.The Buhler 400 model is designed to optimize performance and energy efficiency. It features a fully automated control system that allows operators to monitor and adjust settings in real time. This model is equipped with state-of-the-art grinding technology, ensuring uniform particle size and high-quality end products. With a high production capacity, the Buhler 400 meets the demands of large-scale operations while maintaining low energy consumption.

Similar in robustness, the Buhler 375 model integrates advanced milling technologies that contribute to both efficiency and product quality. This model emphasizes precision in milling, guaranteeing consistent results across batches. Additionally, its ergonomic design simplifies maintenance and reduces downtime, making it an excellent choice for modern milling operations.

The Buhler 340 machine is notable for its versatility. It can handle a variety of raw materials, which makes it suitable for diverse applications in the food industry. The Buhler 340 is characterized by its modular design, allowing it to be easily integrated with existing production lines. This model uses patented separation technologies to enhance the quality of the finished product and ensures high recovery rates of valuable by-products.

The Buhler 305 model offers a compact solution tailored for small to medium-sized operations. Despite its size, it boasts impressive performance capabilities. The Buhler 305 features a user-friendly interface that simplifies operation and monitoring processes. Moreover, its robust construction and low maintenance requirements make it a cost-effective option for those looking to invest in reliable milling technology.

In summary, the Buhler 400, 375, 340, and 305 models showcase a blend of innovation, efficiency, and user-oriented design. Each model includes unique features and technologies tailored to meet varying production needs, aligning with Buhler’s dedication to enhancing food processing operations globally. These machines represent the cutting edge of milling technology, setting new standards for performance and sustainability in the industry.