|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| SECTION V | |

|

|

|

|

|

|

| DEALER ASSEMBLY | ||

|

|

|

| CAUTION | AFTER COMPLETING ANY ASSEMBLY STEP, | ||||

|

|

|

|

|

|

|

|

| THOROUGHLY READ THE NEXT STEP IN THE |

| THE FOLLOWING SAFETY PRECAUTIONS | ASSEMBLY INSTRUCTIONS BEFORE PRO- | |||||||

| SHOULD BE THOROUGHLY UNDERSTOOD | CEEDING WITH THAT STEP. | |||||||

| BEFORE ATTEMPTING MACHINE ASSEMBLY. | 11. After completing assembly, thoroughly inspect | |||||||

|

| 1. Wear personal protective equipment such as, | |||||||

|

| the machine to be sure that all nuts, bolts, hydraulic | |||||||

| but not limited to, protection for eyes, ears, feet, | fittings or any other fastened assemblies have been | |||||||

| hands, lungs and head when assembling the equip- | thoroughly tightened. | |||||||

| ment. Do not wear loose clothing or jewelry that may | 12. After completing assembly, be sure that all | |||||||

| catch on equipment moving parts. | safety locking devices or guards are in place. | |||||||

|

| 2. Do not lift heavy parts or assemblies. Use | 13. Before operating the machine, thoroughly | ||||||

| crane, jack, tackle, fork trucks or other mechanical | read the operation section of this manual. | |||||||

| devices. |

|

|

|

|

|

| 14. Before operating the machine, read the main- | |

|

| 3. Select an area for assembly that is clean and | tenance section of this manual to be sure that any | ||||||

| free of any debris which might cause persons work- | parts requiring lubrication such as gearboxes are full | |||||||

| ing on the assembly to trip. | to avoid any possible damage. | |||||||

|

| 4. Arrange parts to be assembled neatly in the | |||||||

| work area and have tools or other mechanical assist- | BEFORE OPERATING THE EQUIPMENT, IF YOU | |||||||

| ing devices in easy reach. | HAVE ANY QUESTIONS REGARDING THE | |||||||

|

| 5. Inspect all parts and assemblies thoroughly and | PROPER ASSEMBLY OR OPERATION, CON- | ||||||

| remove any sharp edges, grease, oil or dirt which- | TACT YOUR AUTHORIZED BUSH HOG DEALER | |||||||

| might cause pieces to slip when handling. | OR REPRESENTATIVE. | |||||||

|

| 6. Preview the assembly instructions in your oper- | |||||||

| ator’s manual before proceeding further. |

| |||||||

|

| 7. If the assembly instructions call for parts or | |||||||

| assemblies to be blocked up, use only blocking | A. Attach lower lift links to deck assembly using | |||||||

| material that is in good condition and is capable of | 1/2 x 2” bolts, pivot bushings, flatwashers, lockwash- | |||||||

| handling the weight of the assembly to be blocked. | ers, and hex nuts. Two holes are provided to allow | |||||||

| Also, insure that the blocking material is on a clean, | positioning the mower for clearance between the | |||||||

| dry surface. |

|

|

|

|

|

| tractor tires and the mower. (Figure | |

|

| 8. Never put hands or any other part of body | B. Install lift pins onto lower links, securing with | ||||||

| under blocked up assemblies if at all possible. | 7/8” lockwashers and hex nuts. | |||||||

|

| 9. Always wear goggles or safety glasses when | C. Attach mast halves to deck assembly using 1/2 | ||||||

| hammering, grinding, or drilling metal parts. | x | |||||||

|

| 10. If the assembly calls for welding or cutting, be | D. Loosely attach two caster arms to the front of | ||||||

| sure that there are no flammable materials close at | the mower deck using 5/8 x | |||||||

| hand and that bystanders have taken necessary pre- | ers and hex nuts. Loosely attach the remaining two | |||||||

| cautions. |

|

|

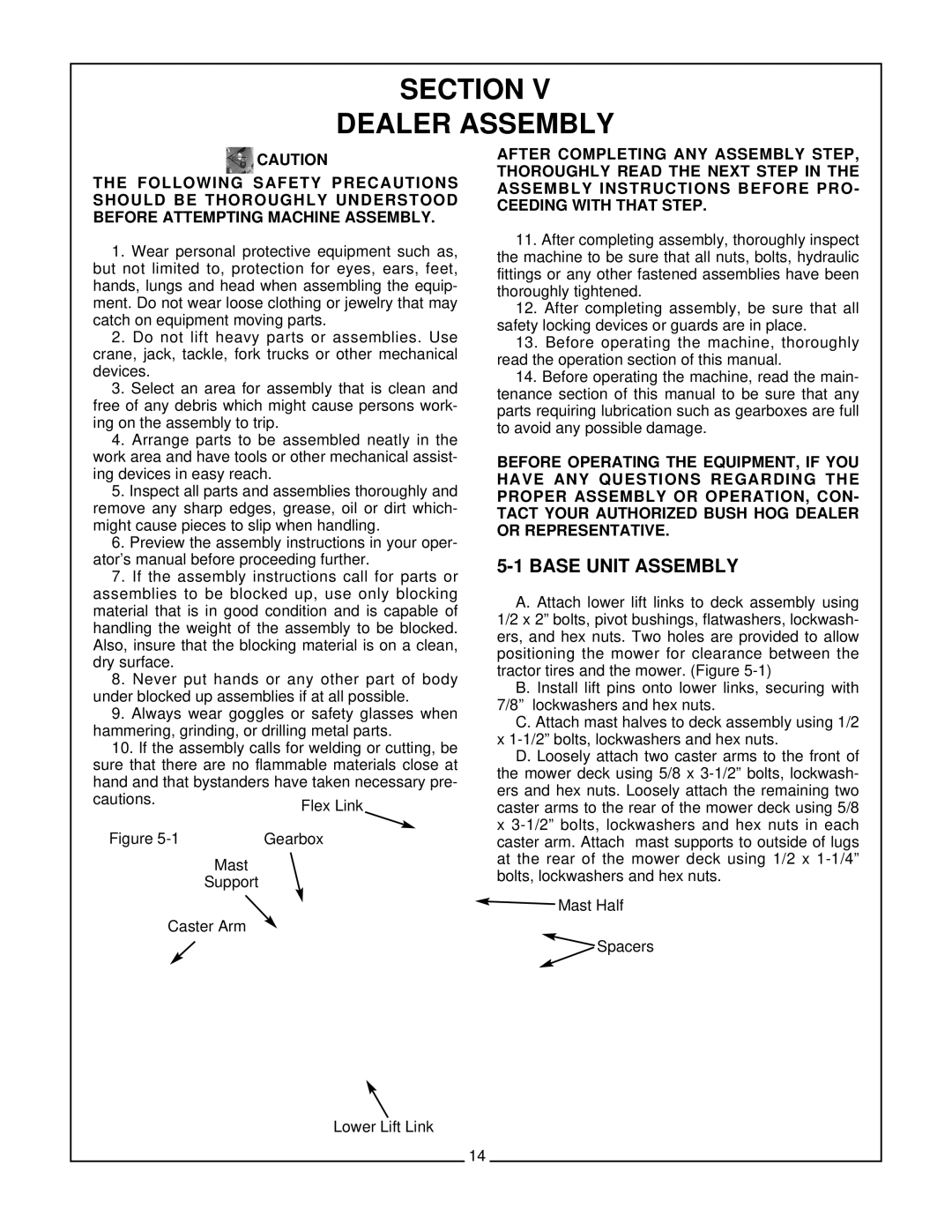

| Flex Link |

| caster arms to the rear of the mower deck using 5/8 | ||

|

|

|

|

|

|

|

|

| |

|

| Figure |

|

| Gearbox |

|

| x | |

|

|

|

|

|

| caster arm. Attach mast supports to outside of lugs | |||

|

|

| Mast |

|

|

|

|

| at the rear of the mower deck using 1/2 x |

|

|

| Support |

|

| bolts, lockwashers and hex nuts. | |||

|

|

|

|

|

|

|

|

| Mast Half |

Caster Arm | Spacers |

|

Lower Lift Link

14