48PG03---16 specifications

The Carrier 48PG03---16 is a standout model in the realm of commercial rooftop air conditioning units, offering innovative technology and exceptional performance for a variety of applications. Designed with rigorous industry standards in mind, this unit combines efficiency, durability, and advanced features, making it a popular choice for both small and medium-sized commercial buildings.One of the main features of the 48PG03---16 is its impressive cooling capacity, which allows it to effectively regulate indoor temperatures even in the hottest climates. The unit boasts a nominal cooling capacity of 3 tons, making it suitable for spaces that require consistent cooling throughout the hot months. Its effective cooling is complemented by an energy-efficient design that uses advanced refrigeration technology to maximize performance while minimizing energy consumption.

This Carrier model is equipped with a high-efficiency scroll compressor, which contributes to its reliability and overall low operational noise. The use of scroll compression technology ensures smooth operation and reduces the risk of mechanical failure, making this unit a long-term investment for building owners. Additionally, the 48PG03---16 features a robust heat exchanger designed to optimize heat transfer efficiency and ensure reliable performance across a wide range of outdoor conditions.

In terms of controls and management, the Carrier 48PG03---16 allows for advanced programmability, facilitating better temperature control and energy management. The unit can be easily integrated with smart building technologies, enabling users to monitor and adjust settings remotely for enhanced convenience and efficiency.

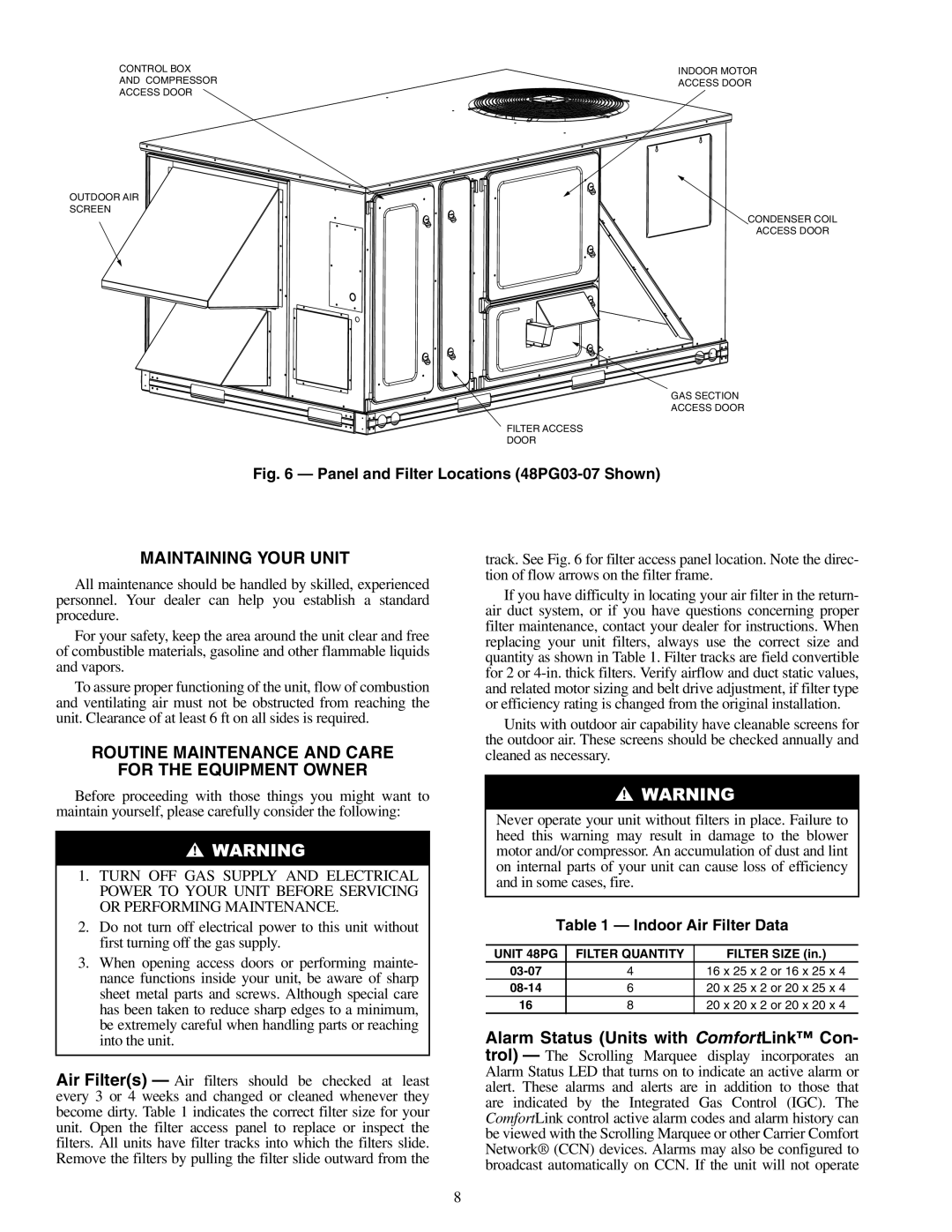

Durability is another hallmark of the Carrier 48PG03---16. Constructed with weather-resistant materials and equipped with a protective cover for critical components, this unit can withstand various environmental factors, including moisture and debris. Its compact design also makes it an ideal fit for rooftop installations, saving valuable ground space.

In summary, the Carrier 48PG03---16 embodies a blend of performance, efficiency, and durability tailored for commercial applications. With its advanced technologies, user-friendly controls, and robust construction, it not only meets but exceeds the expectations of building owners and facility managers looking for a reliable HVAC solution. Whether for retail spaces, office buildings, or larger facilities, the Carrier 48PG03---16 remains a top contender in commercial air conditioning.