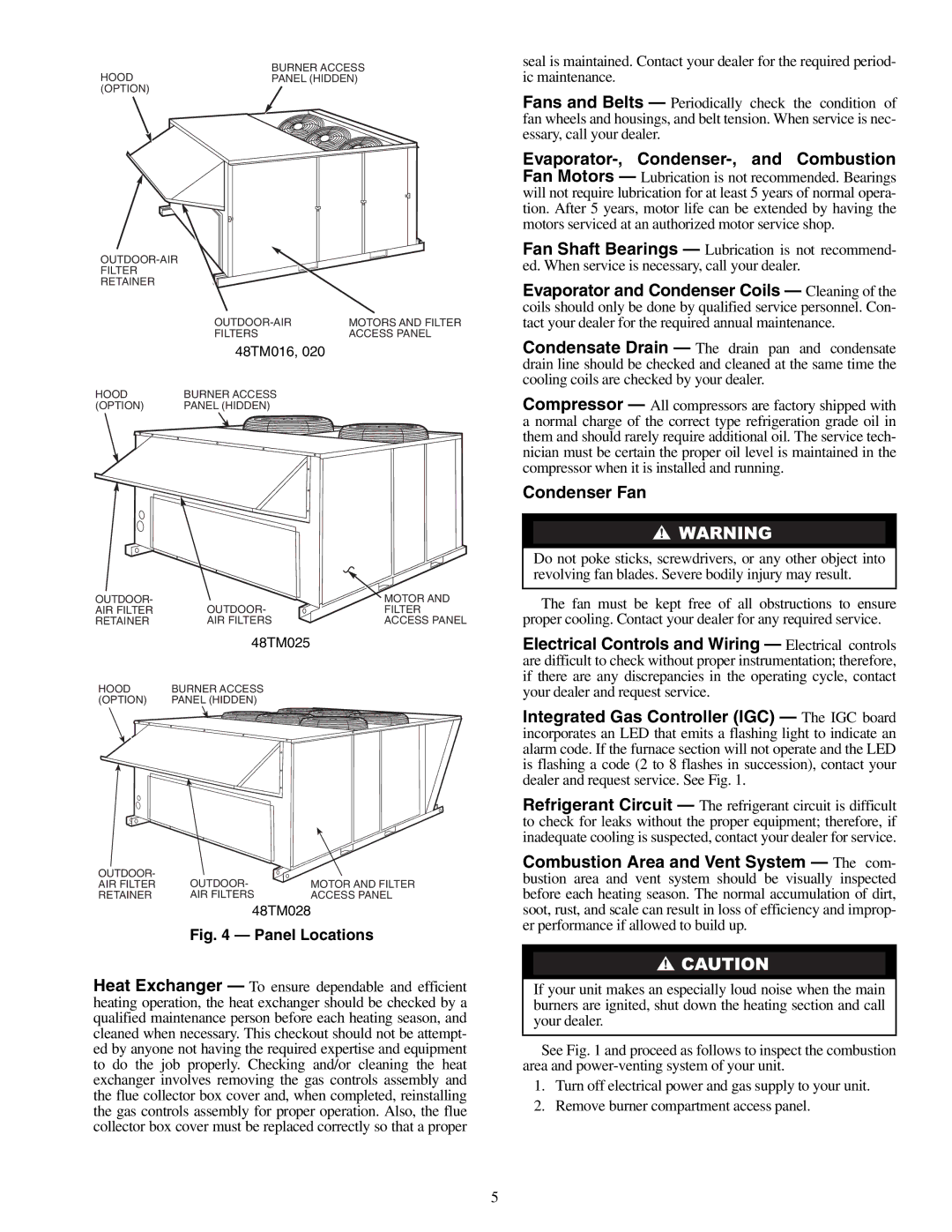

BURNER ACCESS

HOODPANEL (HIDDEN) (OPTION)

FILTER

RETAINER

MOTORS AND FILTER | |

FILTERS | ACCESS PANEL |

48TM016, 020

HOOD | BURNER ACCESS |

(OPTION) | PANEL (HIDDEN) |

OUTDOOR- |

| MOTOR AND |

AIR FILTER | OUTDOOR- | FILTER |

RETAINER | AIR FILTERS | ACCESS PANEL |

| 48TM025 |

|

HOOD | BURNER ACCESS |

|

(OPTION) | PANEL (HIDDEN) |

|

OUTDOOR- | OUTDOOR- | MOTOR AND FILTER |

AIR FILTER | ||

RETAINER | AIR FILTERS | ACCESS PANEL |

48TM028

Fig. 4 — Panel Locations

Heat Exchanger — To ensure dependable and efficient heating operation, the heat exchanger should be checked by a qualified maintenance person before each heating season, and cleaned when necessary. This checkout should not be attempt- ed by anyone not having the required expertise and equipment to do the job properly. Checking and/or cleaning the heat exchanger involves removing the gas controls assembly and the flue collector box cover and, when completed, reinstalling the gas controls assembly for proper operation. Also, the flue collector box cover must be replaced correctly so that a proper

seal is maintained. Contact your dealer for the required period- ic maintenance.

Fans and Belts — Periodically check the condition of fan wheels and housings, and belt tension. When service is nec- essary, call your dealer.

Fan Shaft Bearings — Lubrication is not recommend- ed. When service is necessary, call your dealer.

Evaporator and Condenser Coils — Cleaning of the coils should only be done by qualified service personnel. Con- tact your dealer for the required annual maintenance.

Condensate Drain — The drain pan and condensate drain line should be checked and cleaned at the same time the cooling coils are checked by your dealer.

Compressor — All compressors are factory shipped with a normal charge of the correct type refrigeration grade oil in them and should rarely require additional oil. The service tech- nician must be certain the proper oil level is maintained in the compressor when it is installed and running.

Condenser Fan

Do not poke sticks, screwdrivers, or any other object into revolving fan blades. Severe bodily injury may result.

The fan must be kept free of all obstructions to ensure proper cooling. Contact your dealer for any required service.

Electrical Controls and Wiring — Electrical controls are difficult to check without proper instrumentation; therefore, if there are any discrepancies in the operating cycle, contact your dealer and request service.

Integrated Gas Controller (IGC) — The IGC board incorporates an LED that emits a flashing light to indicate an alarm code. If the furnace section will not operate and the LED is flashing a code (2 to 8 flashes in succession), contact your dealer and request service. See Fig. 1.

Refrigerant Circuit — The refrigerant circuit is difficult to check for leaks without the proper equipment; therefore, if inadequate cooling is suspected, contact your dealer for service.

Combustion Area and Vent System — The com- bustion area and vent system should be visually inspected before each heating season. The normal accumulation of dirt, soot, rust, and scale can result in loss of efficiency and improp- er performance if allowed to build up.

If your unit makes an especially loud noise when the main burners are ignited, shut down the heating section and call your dealer.

See Fig. 1 and proceed as follows to inspect the combustion area and

1.Turn off electrical power and gas supply to your unit.

2.Remove burner compartment access panel.

5