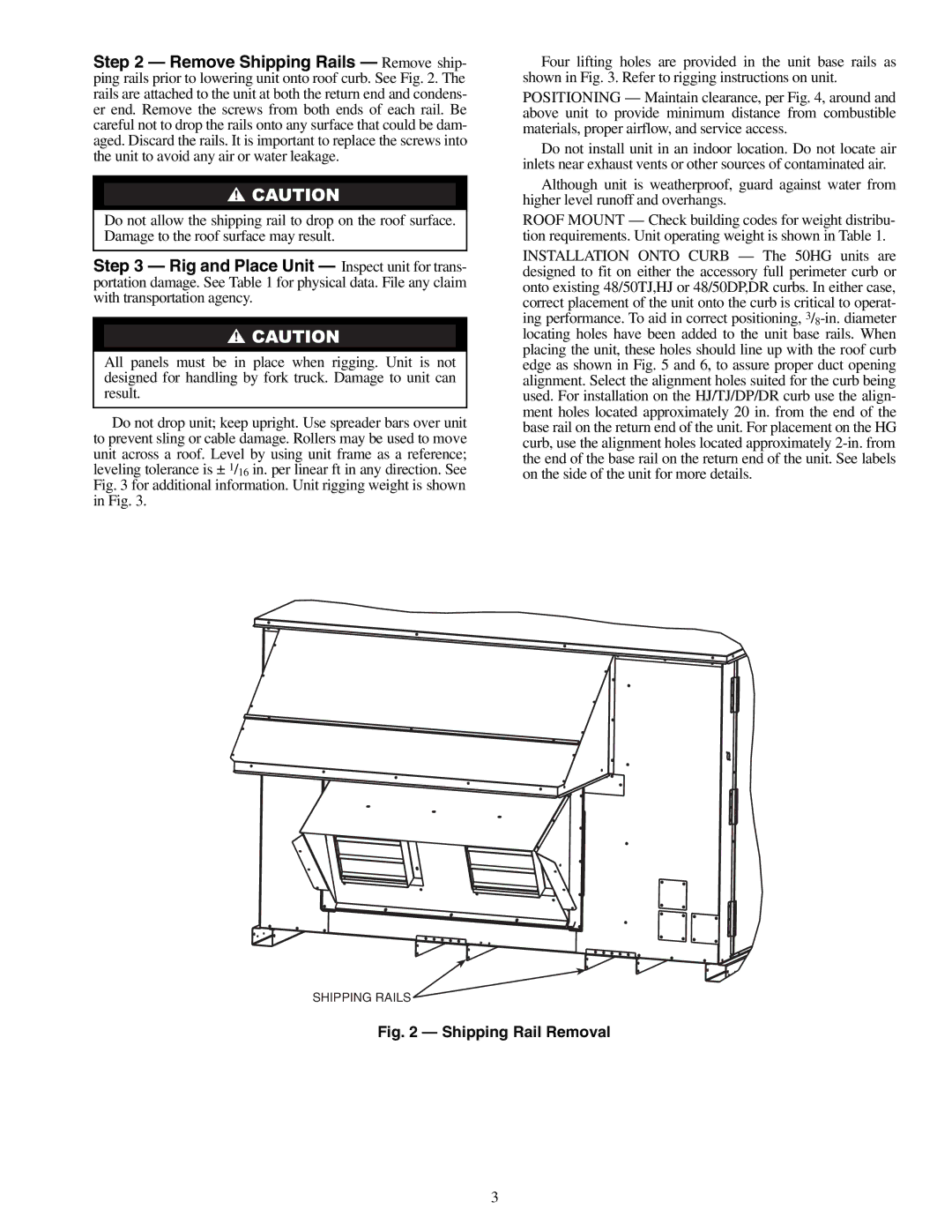

Step 2 — Remove Shipping Rails — Remove ship- ping rails prior to lowering unit onto roof curb. See Fig. 2. The rails are attached to the unit at both the return end and condens- er end. Remove the screws from both ends of each rail. Be careful not to drop the rails onto any surface that could be dam- aged. Discard the rails. It is important to replace the screws into the unit to avoid any air or water leakage.

Do not allow the shipping rail to drop on the roof surface. Damage to the roof surface may result.

Step 3 — Rig and Place Unit — Inspect unit for trans- portation damage. See Table 1 for physical data. File any claim with transportation agency.

All panels must be in place when rigging. Unit is not designed for handling by fork truck. Damage to unit can result.

Do not drop unit; keep upright. Use spreader bars over unit to prevent sling or cable damage. Rollers may be used to move unit across a roof. Level by using unit frame as a reference; leveling tolerance is ± 1/16 in. per linear ft in any direction. See Fig. 3 for additional information. Unit rigging weight is shown in Fig. 3.

Four lifting holes are provided in the unit base rails as shown in Fig. 3. Refer to rigging instructions on unit.

POSITIONING — Maintain clearance, per Fig. 4, around and above unit to provide minimum distance from combustible materials, proper airflow, and service access.

Do not install unit in an indoor location. Do not locate air inlets near exhaust vents or other sources of contaminated air.

Although unit is weatherproof, guard against water from higher level runoff and overhangs.

ROOF MOUNT — Check building codes for weight distribu- tion requirements. Unit operating weight is shown in Table 1.

INSTALLATION ONTO CURB — The 50HG units are designed to fit on either the accessory full perimeter curb or onto existing 48/50TJ,HJ or 48/50DP,DR curbs. In either case, correct placement of the unit onto the curb is critical to operat- ing performance. To aid in correct positioning,

SHIPPING RAILS ![]()

Fig. 2 — Shipping Rail Removal

3