345C L specifications

The CAT 345C L is a versatile and powerful hydraulic excavator designed to tackle a wide range of heavy-duty applications. Renowned for its reliability and efficiency, the CAT 345C L is especially suitable for construction, mining, and demolition tasks. Its robust build and advanced technologies make it a top choice for contractors looking to optimize their productivity.One of the standout features of the CAT 345C L is its impressive engine performance. Powered by a CAT C9 engine, it delivers exceptional horsepower and torque, allowing for faster cycle times and increased productivity. This engine meets stringent emissions standards, ensuring that operations are not only powerful but also environmentally responsible. The hydraulic system is designed for enhanced control and efficiency, providing excellent lifting capabilities and precise maneuverability.

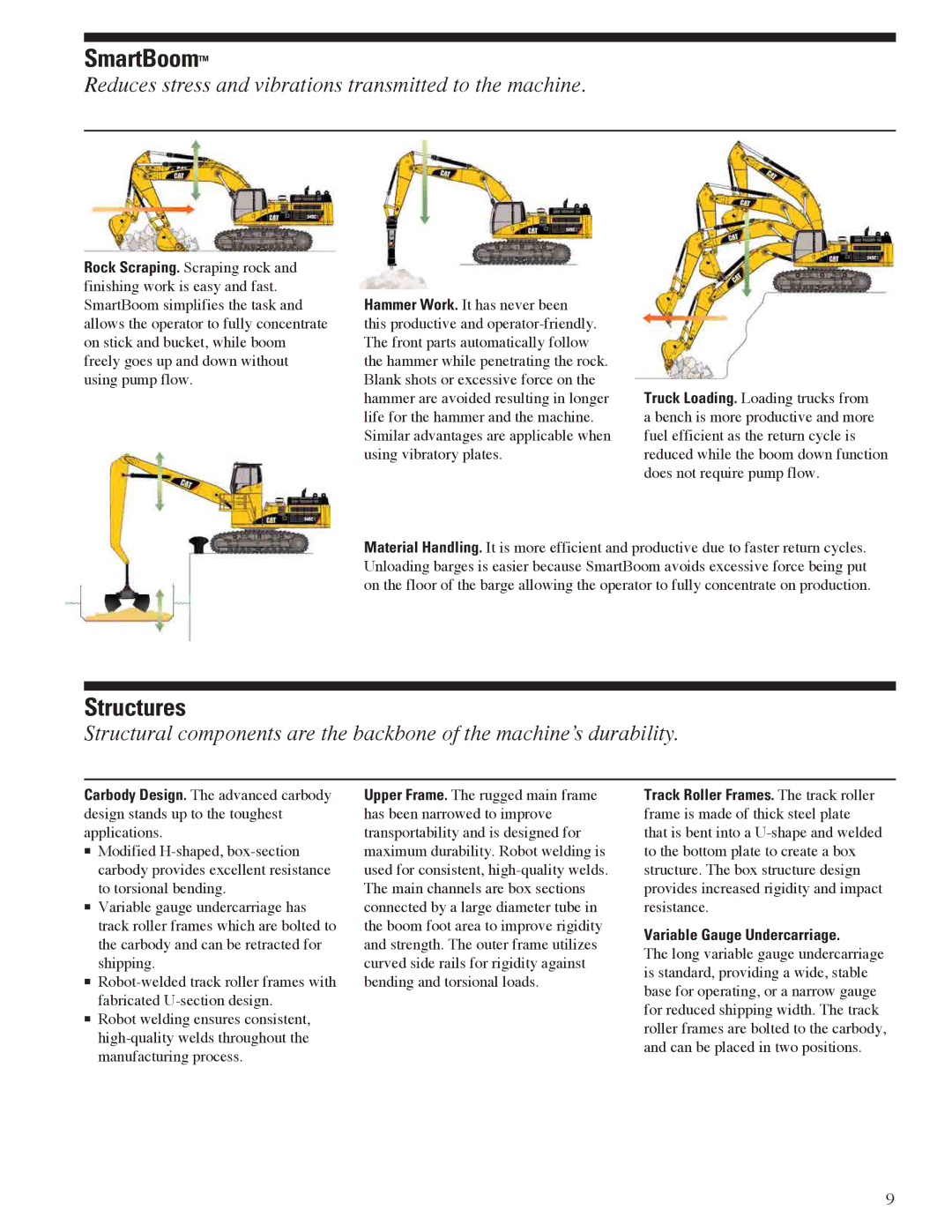

The machine boasts a maximum digging depth of approximately 7 meters (23 feet) and a reach of nearly 11 meters (36 feet), making it suitable for deep excavation projects and reaching challenging areas. The boom and arm design is optimized for maximum breakout force, allowing for more effective material handling and digging performance.

In terms of operator comfort, the CAT 345C L features a spacious and ergonomic cab. It is equipped with large windows for improved visibility, reducing blind spots and enhancing safety. The adjustable seat, intuitive controls, and air conditioning system ensure that operators can work efficiently and comfortably during long shifts.

Technologically, the CAT 345C L integrates the latest advancements in excavator design. The machine features the Cat Product Link system, which provides real-time data regarding the machine’s performance and health. This functionality allows operators and fleet managers to make informed decisions based on actual usage and status, thereby reducing downtime and maintenance costs.

Durability is a key characteristic of the CAT 345C L, as it is constructed with high-strength materials designed to withstand the rigors of challenging work environments. Each component is engineered for longevity, minimizing wear and tear and extending the lifespan of the excavator.

Overall, the CAT 345C L is a powerful, efficient, and operator-friendly excavator that embodies the quality and innovation associated with the CAT brand. Its combination of performance, comfort, and advanced technology makes it an essential machine for heavy construction and earthmoving projects.