Natural Gas to LPG Conversion

This hob can be converted from natural gas to propane operation at a nominal inlet pressure of 37mbar, or butane operation at a nominal inlet pressure of 28/30mbar. This conversion must only be carried out by a competent person (i.e. a Gas Safe registered fitter).

Instructions to fit replacement injectors: |

| Required: | ||||

• 7mm AF nut spinner | ||||||

|

|

|

| |||

1. | Disconnect the appliance from the gas and electrical supplies. | • | Replacement injectors | |||

2. | Remove burner components and pan supports. | • | LPG identity plate | |||

3. | Remove the injectors and replace with the corresponding |

|

|

|

| |

|

|

| ||||

| injector as shown in the table below. |

| Fig.6 | |||

Setting up minimum flow rates:

1.Remove the control knobs.

2.Turn on the LP gas supply, light the burners and turn the controls to the minimum position, as indicated by the small flame.

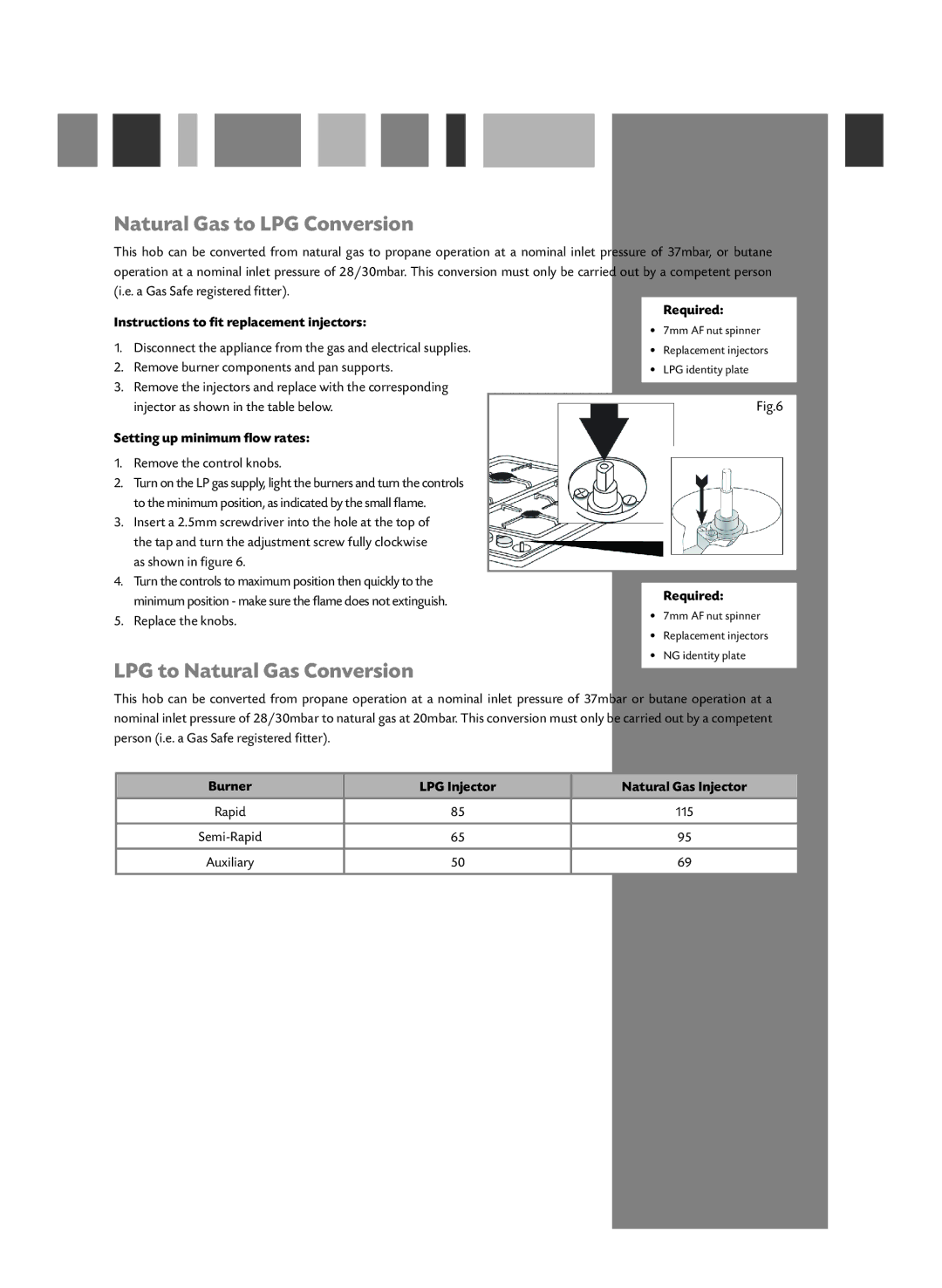

3.Insert a 2.5mm screwdriver into the hole at the top of the tap and turn the adjustment screw fully clockwise as shown in figure 6.

4.Turn the controls to maximum position then quickly to the

minimum position - make sure the flame does not extinguish. | Required: |

| |

5. Replace the knobs. | • 7mm AF nut spinner |

| |

| • Replacement injectors |

LPG to Natural Gas Conversion | • NG identity plate |

| |

|

This hob can be converted from propane operation at a nominal inlet pressure of 37mbar or butane operation at a nominal inlet pressure of 28/30mbar to natural gas at 20mbar. This conversion must only be carried out by a competent person (i.e. a Gas Safe registered fitter).

Burner | LPG Injector | Natural Gas Injector | |

Rapid | 85 | 115 | |

|

|

| |

65 | 95 | ||

|

|

| |

Auxiliary | 50 | 69 | |

|

|

|