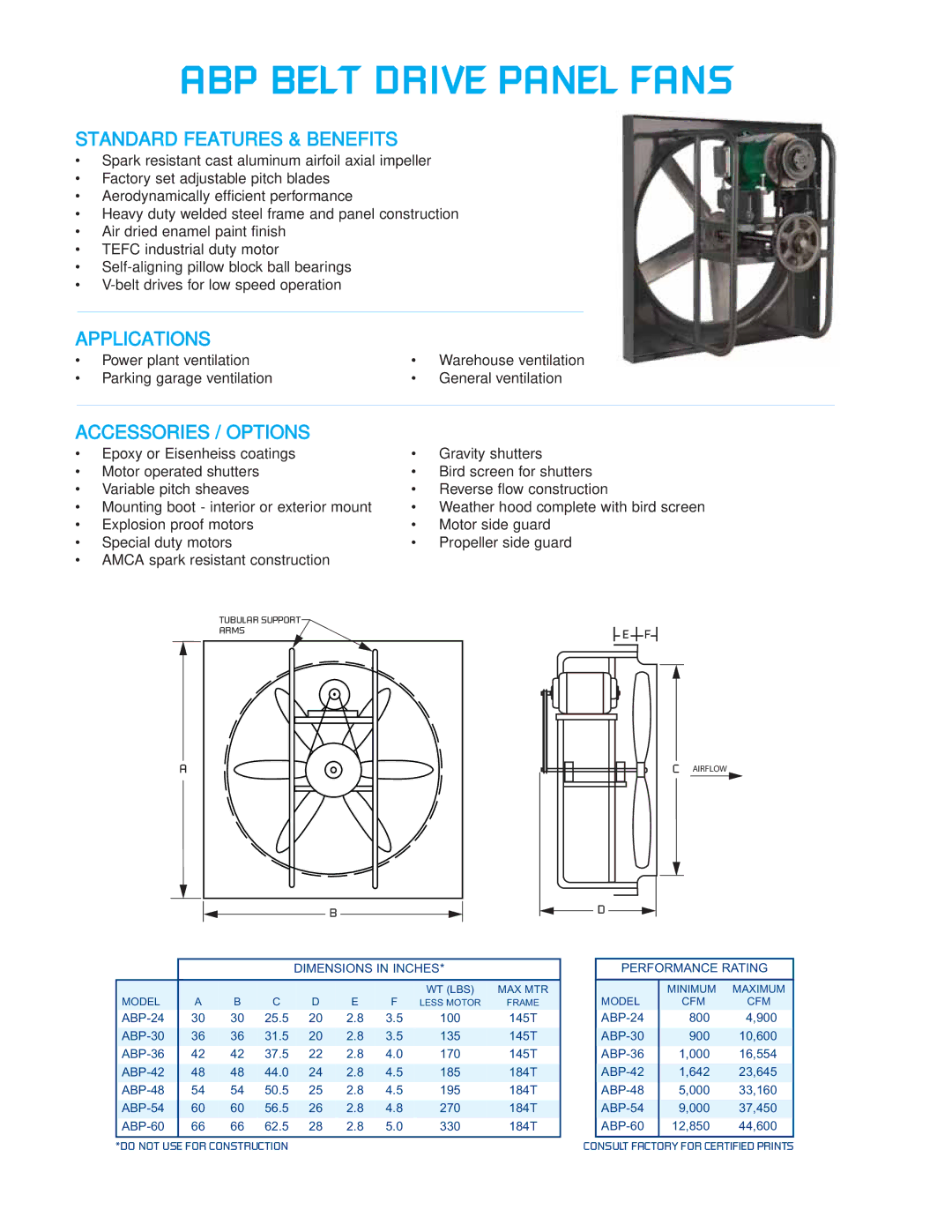

ABP-24, ABP-42, ABP-54, ABP-30, ABP-36 specifications

CFM International, a leading firm in aircraft engine manufacturing, is known for its innovative products, including the ABP series of engines. The ABP-48, ABP-30, ABP-0905, ABP-36, and ABP-60 engines are designed for various applications, each showcasing unique features, advanced technologies, and distinctive characteristics.The CFM ABP-48 engine stands out for its high efficiency and low emissions, making it an ideal choice for regional and business aviation. It incorporates state-of-the-art materials that enhance performance while reducing overall weight. Additionally, its advanced digital engine control system optimizes fuel consumption and operational reliability, ensuring minimal environmental impact.

In contrast, the ABP-30 engine emphasizes compact design and adaptability, targeting small to medium-sized aircraft. One of its key features is the advanced noise reduction technology, which meets strict noise regulations while improving passenger comfort. Equipped with a robust thrust-to-weight ratio, the ABP-30 also excels in short takeoff and landing scenarios, making it a versatile choice for various flying conditions.

The ABP-0905 engine is engineered for high-performance applications, often favored in military and specialized aircraft. Its standout technologies include variable fan geometry and augmented thrust capabilities, allowing for exceptional maneuverability and responsiveness. The ABP-0905 also employs advanced thermal barrier coatings that enhance durability under extreme conditions, making it a reliable choice for demanding environments.

Meanwhile, the ABP-36 model targets the commercial airline sector, where efficiency and long-range capabilities are crucial. This engine boasts a highly efficient core that optimizes fuel burn while delivering impressive thrust. Its innovative modular design simplifies maintenance, promoting easier overhauls and reduced operational downtime.

Lastly, the ABP-60 engine is a testament to CFM's commitment to sustainability. It features cutting-edge technologies that significantly reduce carbon emissions, aligning with global environmental goals. Its advanced diagnostic systems provide real-time performance monitoring, ensuring operators can maximize efficiency and maintain safety.

In summary, the CFM ABP series engines, including the ABP-48, ABP-30, ABP-0905, ABP-36, and ABP-60, exemplify cutting-edge aircraft engine technology. Each model is crafted with specific applications in mind, leveraging advancements to push the boundaries of performance, efficiency, and sustainability in aviation.