WIRING

WARNING: Hazard of Shock. Any installation involving electric heaters must be effectively grounded in accordance with the National Electrical Code to elim- inate shock hazard.

1.Electrical wiring to heater must be installed in accordance with the National Electrical Code and local electric codes by a qualified person as defined in the NEC.

2.When element wattages are not equal, heaters must not be con- nected in series.

3.Electrical wiring to heater should be contained in Rigid Conduit or in sealed Flexible Metal hose to keep corrosive vapors and liquid out of the terminal housing. Conduit should terminate at some remote area free of corrosive vapors. If high humidity is encoun- tered, the conduit should slope away from the heater terminals to keep condensate away from the heater.

4.If flexible cord is employed with the heater, a watertight connec- tor should be used for entry of the cord into the terminal box.

5.Make sure heater is grounded by attaching ground conductor, traceable back to service entrance, to the ground terminal located

inside the terminal box. If heater is used in an electroplating tank, the heater should be grounded externally to the tank wall to mini- mize stray plating currents in heater sheath that may cause sheath corrosion.

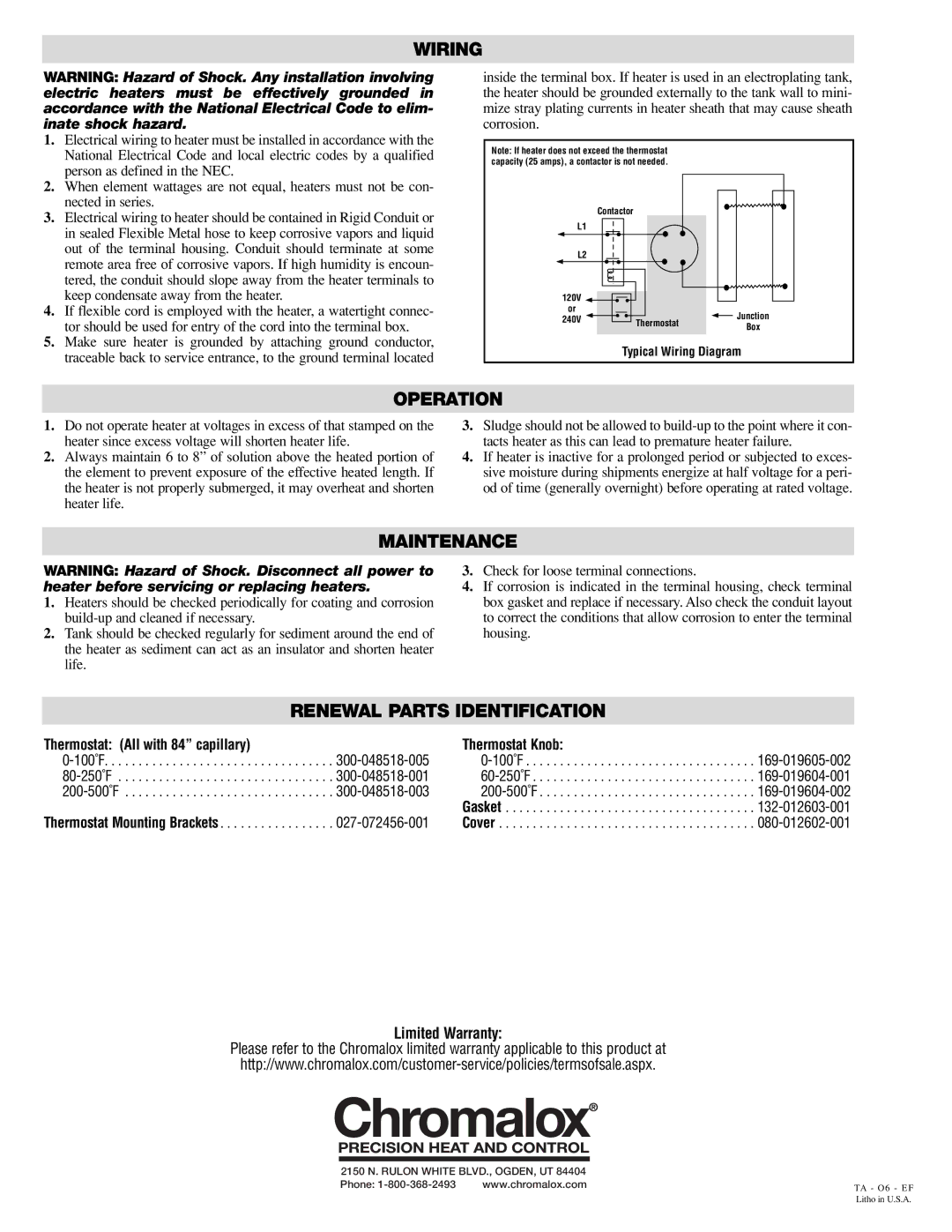

Note: If heater does not exceed the thermostat capacity (25 amps), a contactor is not needed.

Contactor

L1

L2

120V

or

240V ![]()

![]() ThermostatJunction Box

ThermostatJunction Box

Typical Wiring Diagram

OPERATION

1.Do not operate heater at voltages in excess of that stamped on the heater since excess voltage will shorten heater life.

2.Always maintain 6 to 8” of solution above the heated portion of the element to prevent exposure of the effective heated length. If the heater is not properly submerged, it may overheat and shorten heater life.

3.Sludge should not be allowed to

4.If heater is inactive for a prolonged period or subjected to exces- sive moisture during shipments energize at half voltage for a peri- od of time (generally overnight) before operating at rated voltage.

MAINTENANCE

WARNING: Hazard of Shock. Disconnect all power to heater before servicing or replacing heaters.

1.Heaters should be checked periodically for coating and corrosion

2.Tank should be checked regularly for sediment around the end of the heater as sediment can act as an insulator and shorten heater life.

3.Check for loose terminal connections.

4.If corrosion is indicated in the terminal housing, check terminal box gasket and replace if necessary. Also check the conduit layout to correct the conditions that allow corrosion to enter the terminal housing.

RENEWAL PARTS IDENTIFICATION

Thermostat: (All with 84” capillary) |

| Thermostat Knob: |

|

|

| Gasket | |

Thermostat Mounting Brackets | Cover |

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

2150 N. RULON WHITE BLVD., OGDEN, UT 84404 |

| |

Phone: | www.chromalox.com | TA - O6 - EF |

|

| |

Litho in U.S.A.