INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power before installing or servicing heater. Failure to do so could result in personal injury or property dam- age. Heater must be installed or serviced by a qualified person in accordance with the National Electrical Code, NFPA 70.

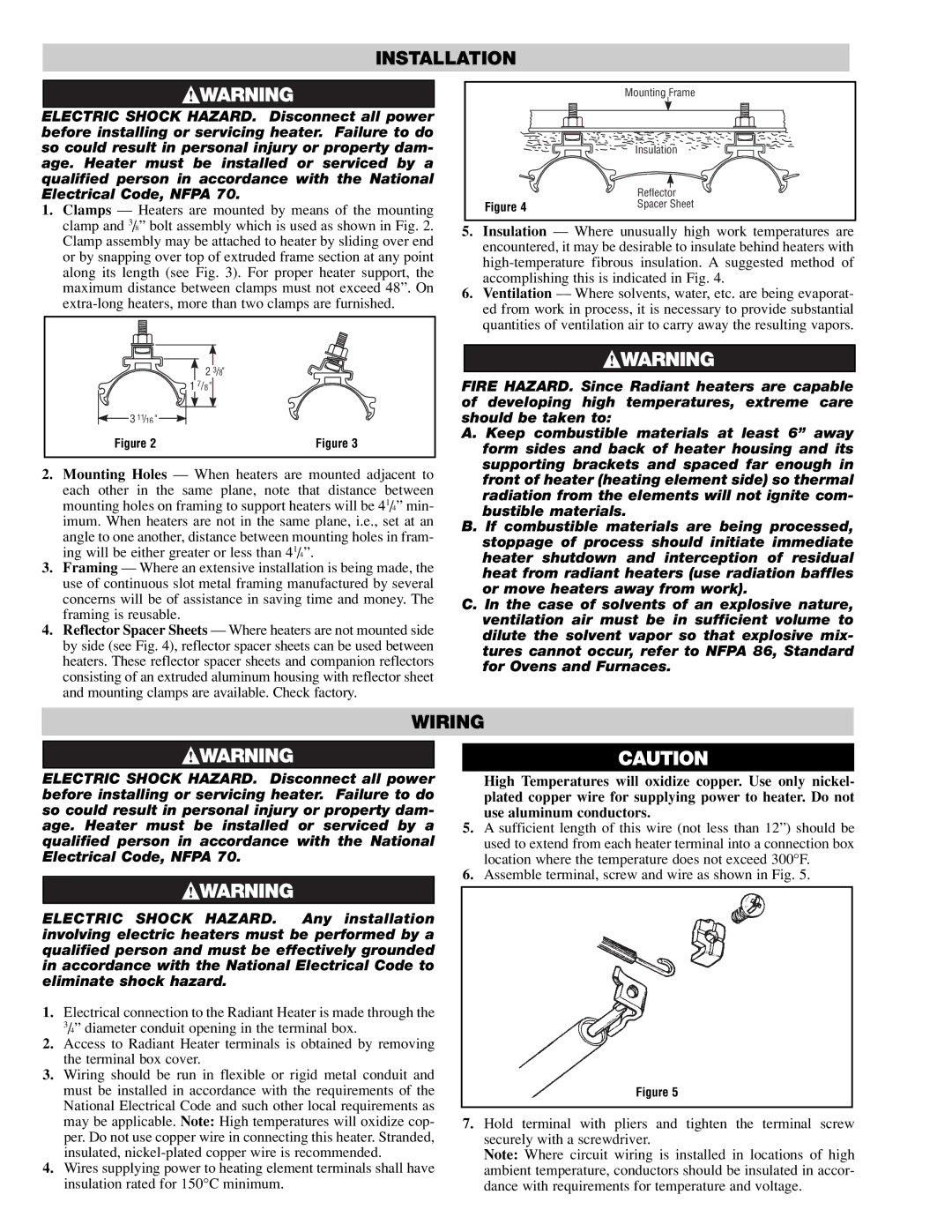

1.Clamps — Heaters are mounted by means of the mounting clamp and 3/8” bolt assembly which is used as shown in Fig. 2. Clamp assembly may be attached to heater by sliding over end or by snapping over top of extruded frame section at any point along its length (see Fig. 3). For proper heater support, the maximum distance between clamps must not exceed 48”. On

2 3/8"

1 7/8 "

3 11/16 "

Figure 2 | Figure 3 |

2.Mounting Holes — When heaters are mounted adjacent to each other in the same plane, note that distance between mounting holes on framing to support heaters will be 41/4” min- imum. When heaters are not in the same plane, i.e., set at an angle to one another, distance between mounting holes in fram- ing will be either greater or less than 41/4”.

3.Framing — Where an extensive installation is being made, the use of continuous slot metal framing manufactured by several concerns will be of assistance in saving time and money. The framing is reusable.

4.Reflector Spacer Sheets — Where heaters are not mounted side by side (see Fig. 4), reflector spacer sheets can be used between heaters. These reflector spacer sheets and companion reflectors consisting of an extruded aluminum housing with reflector sheet and mounting clamps are available. Check factory.

| Mounting Frame |

| Insulation |

| Reflector |

Figure 4 | Spacer Sheet |

5.Insulation — Where unusually high work temperatures are encountered, it may be desirable to insulate behind heaters with

6.Ventilation — Where solvents, water, etc. are being evaporat- ed from work in process, it is necessary to provide substantial quantities of ventilation air to carry away the resulting vapors.

FIRE HAZARD. Since Radiant heaters are capable of developing high temperatures, extreme care should be taken to:

A. Keep combustible materials at least 6” away form sides and back of heater housing and its supporting brackets and spaced far enough in front of heater (heating element side) so thermal radiation from the elements will not ignite com- bustible materials.

B. If combustible materials are being processed, stoppage of process should initiate immediate heater shutdown and interception of residual heat from radiant heaters (use radiation baffles or move heaters away from work).

C. In the case of solvents of an explosive nature, ventilation air must be in sufficient volume to dilute the solvent vapor so that explosive mix- tures cannot occur, refer to NFPA 86, Standard for Ovens and Furnaces.

WIRING

ELECTRIC SHOCK HAZARD. Disconnect all power before installing or servicing heater. Failure to do so could result in personal injury or property dam- age. Heater must be installed or serviced by a qualified person in accordance with the National Electrical Code, NFPA 70.

ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in accordance with the National Electrical Code to eliminate shock hazard.

1.Electrical connection to the Radiant Heater is made through the 3/4” diameter conduit opening in the terminal box.

2.Access to Radiant Heater terminals is obtained by removing the terminal box cover.

3.Wiring should be run in flexible or rigid metal conduit and must be installed in accordance with the requirements of the National Electrical Code and such other local requirements as may be applicable. Note: High temperatures will oxidize cop- per. Do not use copper wire in connecting this heater. Stranded, insulated,

4.Wires supplying power to heating element terminals shall have insulation rated for 150°C minimum.

High Temperatures will oxidize copper. Use only nickel- plated copper wire for supplying power to heater. Do not use aluminum conductors.

5.A sufficient length of this wire (not less than 12”) should be used to extend from each heater terminal into a connection box location where the temperature does not exceed 300°F.

6.Assemble terminal, screw and wire as shown in Fig. 5.

Figure 5

7.Hold terminal with pliers and tighten the terminal screw securely with a screwdriver.

Note: Where circuit wiring is installed in locations of high ambient temperature, conductors should be insulated in accor- dance with requirements for temperature and voltage.