POO400-7 specifications

The Chromalox POO400-7 is a high-quality industrial heater designed to meet a diverse array of heating needs in various applications. Known for its robustness and efficiency, this electric heater stands out with its advanced features, technologies, and characteristics that cater to both heating and safety requirements.One of the standout features of the POO400-7 is its powerful heating capacity. With a rating of 400 watts, it delivers consistent and reliable heat output, making it suitable for applications ranging from process heating to maintaining optimal temperatures in industrial environments. The heater is designed to quickly reach and maintain the desired temperature, ensuring efficient operation and reduced energy consumption.

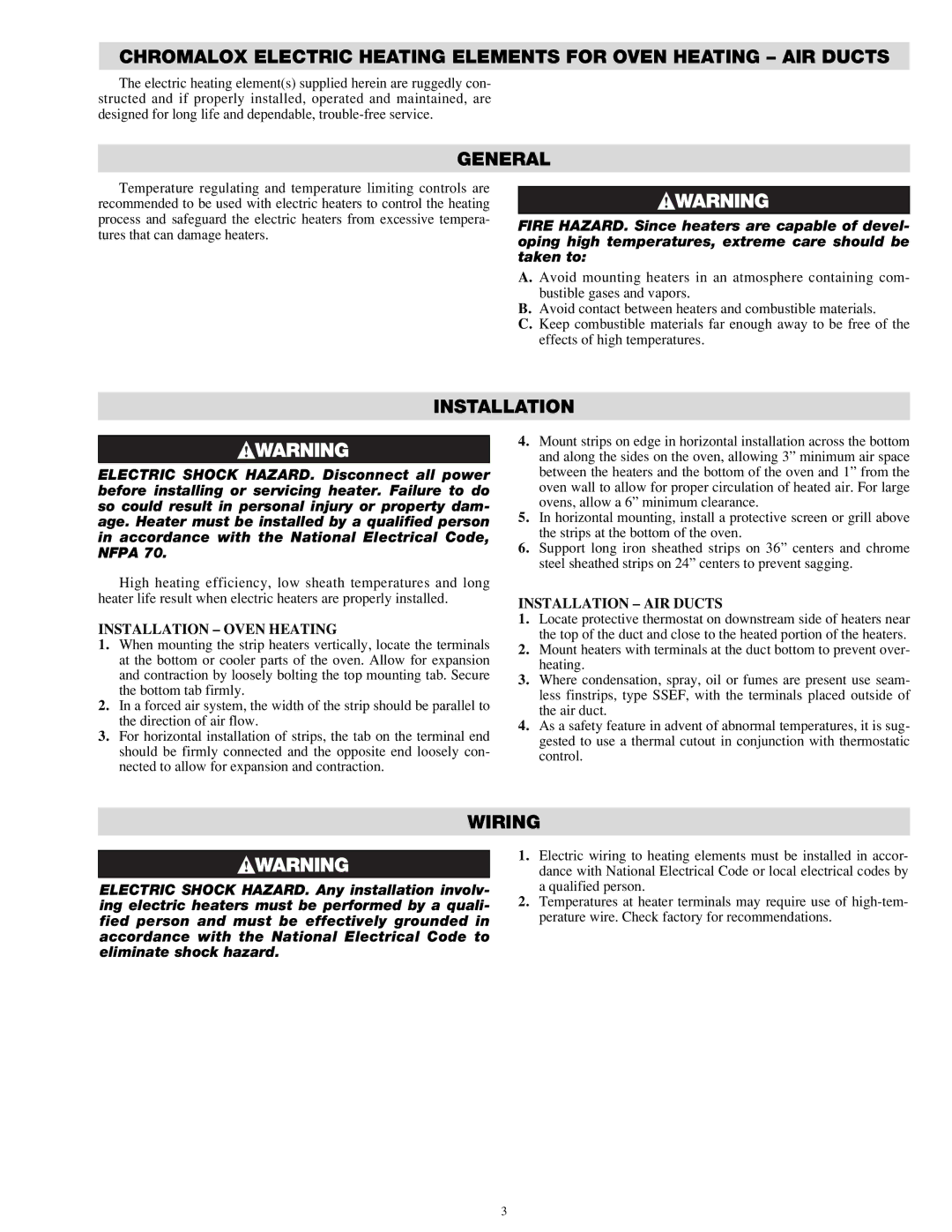

Incorporating advanced heating technology, the Chromalox POO400-7 utilizes precision-engineered heating elements that provide uniform heat distribution. This feature is critical in industrial settings where maintaining specific temperature ranges is vital for process quality and safety. The heater's ability to distribute heat evenly helps prevent hot spots and minimizes the risk of damage to surrounding materials.

Durability is another characteristic that sets the POO400-7 apart. Constructed from high-quality materials, this heater is built to withstand harsh industrial conditions. It features a rugged housing that protects the internal components from dust, moisture, and other contaminants, extending the lifespan of the unit and reducing maintenance costs.

The POO400-7 also prioritizes user safety. It is equipped with several safety features, including over-temperature protection, which automatically shuts off the unit if it exceeds designated temperature limits. This not only helps prevent accidents but also enhances the overall reliability of the heater in demanding environments.

In terms of installation and integration, the Chromalox POO400-7 is designed for versatility. It can be easily mounted or installed in various configurations, making it suitable for different industrial applications. Its lightweight design and compact size also facilitate easy handling and positioning.

Overall, the Chromalox POO400-7 is an exemplary choice for industries seeking a dependable and efficient heating solution. Its combination of powerful performance, advanced technologies, durability, and safety features make it an invaluable asset in various heating applications, from equipment maintenance to process control in demanding industrial settings.