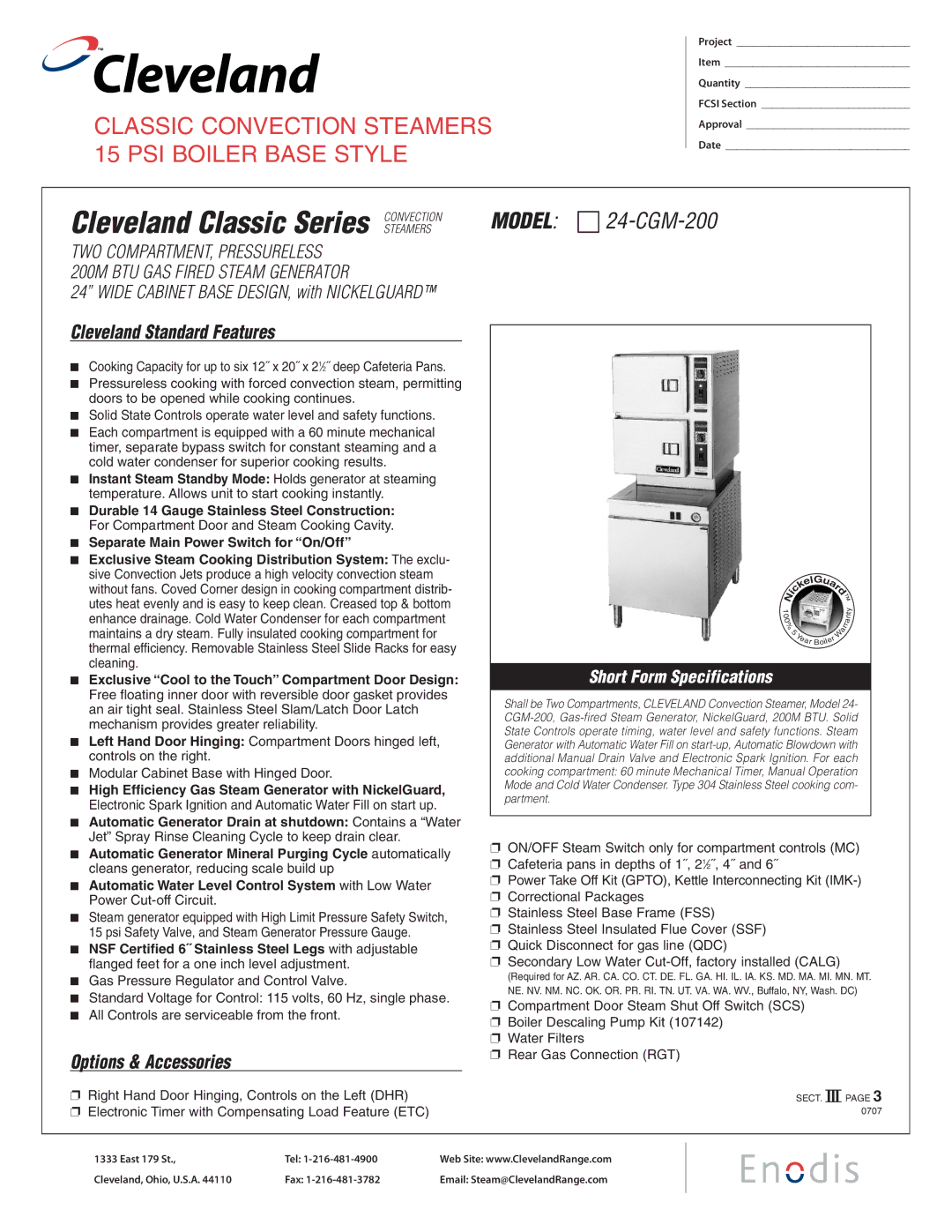

24-CGM-200 specifications

The Cleveland Range 24-CGM-200 is a powerful commercial cooking appliance designed for efficiency and versatility in professional kitchens. Known for its exceptional performance, this gas combi oven boasts a range of features and technologies that cater to the demands of high-volume cooking.One of the standout characteristics of the 24-CGM-200 is its dual cooking modes: steam and convection. This allows chefs to easily adapt their cooking techniques, ensuring that a variety of dishes can be prepared with precision. The steam mode is perfect for cooking delicate items like fish and vegetables, preserving their moisture and nutrients, while the convection mode is ideal for roasting and baking, providing an even heat distribution for consistent results.

The oven is equipped with advanced controls that enhance usability and efficiency. The easy-to-read digital display offers a user-friendly interface that allows chefs to set cooking times and temperatures with precision. This feature significantly reduces the risk of human error, leading to a consistent quality in food preparation.

In addition, the Cleveland Range 24-CGM-200 includes programmable cooking options, enabling users to create and save customized cooking profiles for specific dishes. This capability streamlines kitchen operations, allowing chefs to replicate recipes with exactness, thus improving kitchen workflow and productivity.

Energy efficiency is another hallmark of the 24-CGM-200. Its design incorporates energy-saving technologies, which not only reduce operational costs but also promote environmentally sustainable practices in commercial kitchens. The robust construction of the oven ensures longevity and reliability, with high-quality materials that can withstand the rigors of daily use.

The compact design of the Cleveland Range 24-CGM-200 makes it an ideal choice for kitchens with limited space, while still offering ample cooking capacity. It can easily accommodate large batches of food, making it a valuable asset for restaurants, schools, and catering operations.

Overall, the Cleveland Range 24-CGM-200 stands out for its innovative features, ease of use, and superior cooking performance. Its combination of steam and convection cooking, programmable controls, energy efficiency, and durable construction make it an essential tool for chefs looking to elevate their culinary offerings while maintaining efficiency in the kitchen.