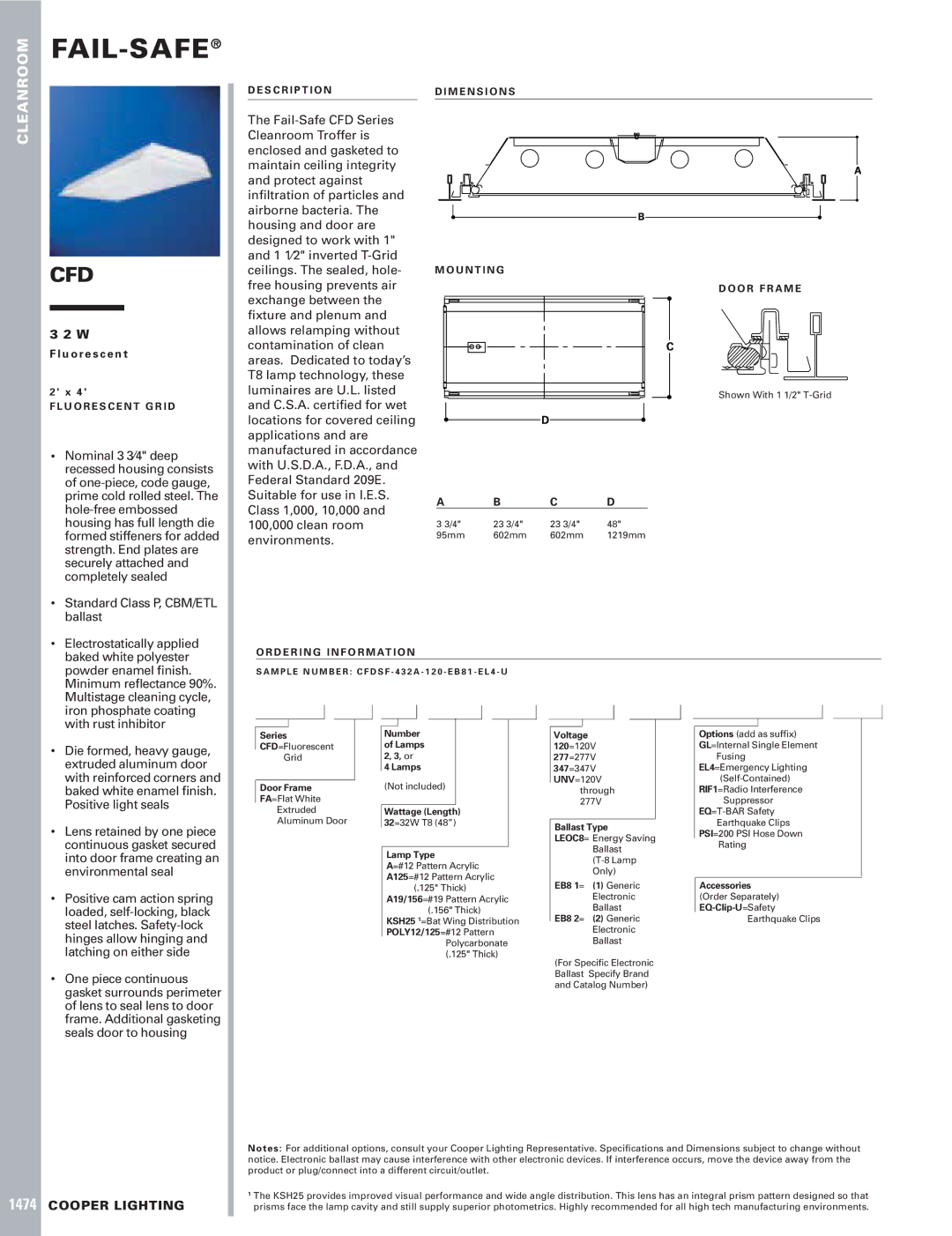

CFD specifications

Cooper Lighting, a division of Signify, has established itself as a leader in the lighting industry, particularly known for its innovative solutions in the field of commercial and industrial lighting. One of the standout products from Cooper Lighting is the Cooper Lighting CFD series. This product line exemplifies advanced technology, energy efficiency, and superior design, making it a preferred choice for various applications.The Cooper Lighting CFD is engineered to deliver exceptional performance while minimizing energy consumption. It features state-of-the-art LED technology, which not only extends the lifespan of the fixtures but also reduces maintenance costs significantly. The longevity of LEDs ensures that facilities can enjoy high-quality illumination for years without the incessant need for replacements.

One of the main characteristics of the CFD series is its versatility. It is designed to accommodate a wide range of installation environments including warehouses, distribution centers, manufacturing plants, and retail spaces. The ability to create different lighting layouts allows facility managers to tailor the lighting according to specific needs, enhancing both safety and productivity.

The CFD series also incorporates advanced optics that help in achieving optimal light distribution. These optics are designed to reduce glare and improve visual comfort, which is critical in environments where employees need to focus on tasks for prolonged periods. The light quality provided by CFD fixtures enhances concentration and reduces eyestrain, contributing to a safer and more efficient workplace.

Moreover, the Cooper Lighting CFD series supports smart lighting solutions. With options for integration into building management systems, facility managers can monitor and control lighting remotely. This capability not only boosts energy efficiency but also allows for data analytics, making it easier to track usage patterns and optimize energy consumption further.

Another notable feature is its robust construction. The CFD fixtures are built to withstand demanding environments, often with features such as corrosion resistance and durable housings. This ensures that the lighting solutions remain reliable even in harsh conditions.

In conclusion, Cooper Lighting CFD exemplifies how modern technology can be harnessed to create efficient, durable, and versatile lighting solutions. With its blend of performance, adaptability, and smart technology features, the CFD series stands out as an essential choice for organizations aiming to enhance their lighting infrastructure while promoting sustainability and reducing operational costs.