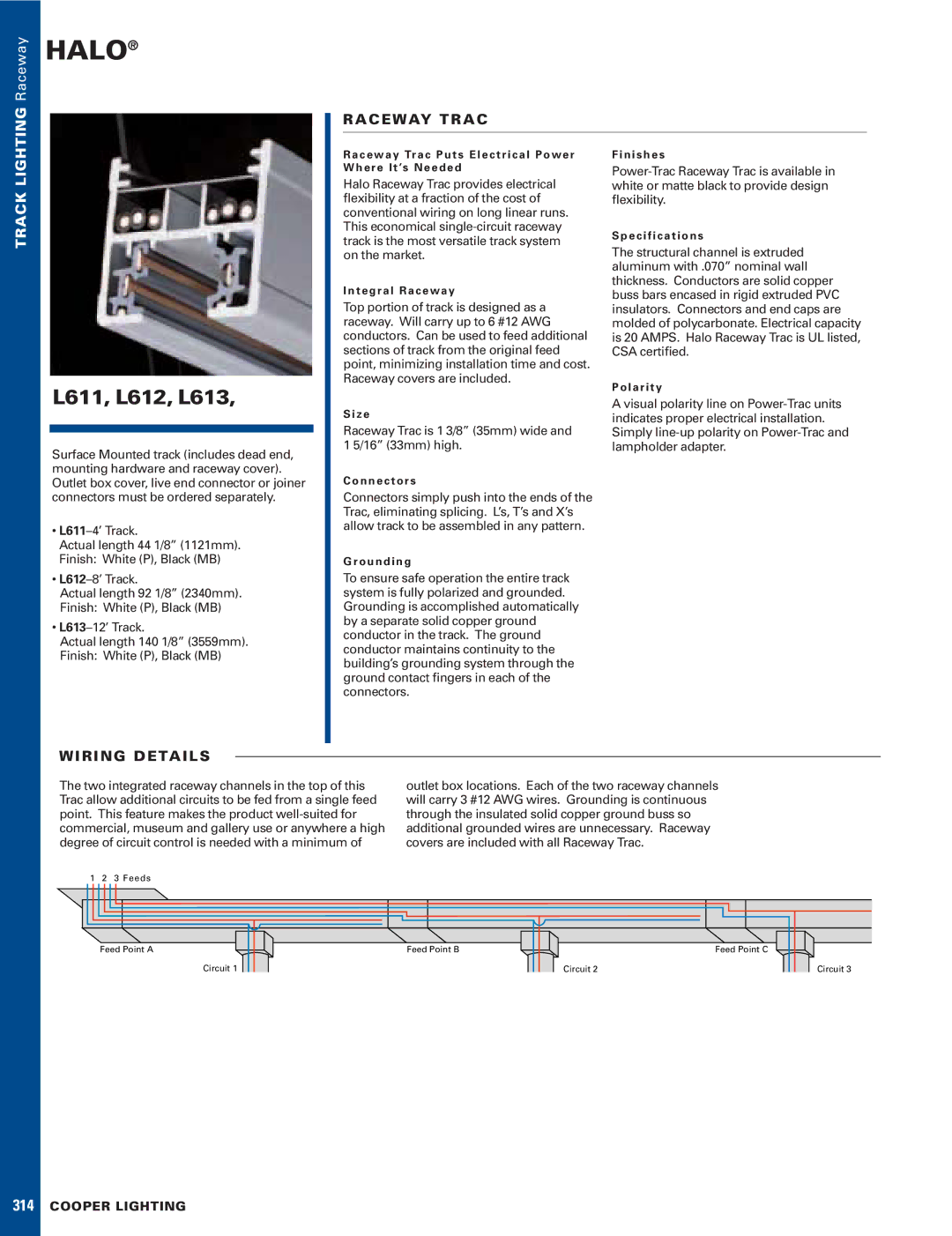

L613, L611, L612 specifications

Cooper Lighting has established itself as a leader in the lighting industry, offering a variety of innovative products designed for efficiency and performance. Among its notable offerings are the L612, L611, and L613 models, which showcase advanced technologies and thoughtful design to meet diverse lighting needs.The L612 model is designed with versatility in mind, making it suitable for a variety of applications. It features an energy-efficient LED system that delivers high lumen output while consuming minimal power. The L612's optical performance is enhanced by its unique lens design, which provides uniform light distribution and minimizes glare. This makes it ideal for spaces requiring focused illumination, such as commercial offices and retail environments. With its durable construction and robust materials, the L612 is built to withstand the rigors of continuous use in high-traffic areas.

The L611 model, on the other hand, emphasizes smart lighting capabilities. It incorporates advanced control systems that allow for dimming, scheduling, and integration with building management systems. This adaptability not only enhances user experience but also promotes energy savings by allowing users to tailor the lighting to their specific needs. The L611’s sleek design complements modern architecture, making it an aesthetically pleasing option for any contemporary setting. The fixture is also crafted with sustainability in mind, using recyclable materials and offering a long lifespan that reduces the frequency of replacements.

Lastly, the L613 model focuses on enhancing safety and security in various environments. It combines powerful LED technology with motion sensors and emergency lighting features, ensuring that spaces are well-lit when needed. The L613 is especially beneficial in outdoor applications, such as parking lots and walkways, where visibility is crucial. Its rugged design and weather-resistant materials ensure reliable performance, even in harsh conditions. Furthermore, the model can be integrated with smart technology for real-time monitoring and response, ensuring a proactive approach to safety.

In summary, Cooper Lighting's L612, L611, and L613 models exemplify the company’s commitment to innovation, efficiency, and safety in lighting solutions. Each model brings unique features and technologies to the table, catering to a wide range of lighting applications while promoting sustainability and energy efficiency. With these products, Cooper Lighting continues to set the standard for high-quality, reliable lighting solutions that meet the diverse needs of modern consumers.