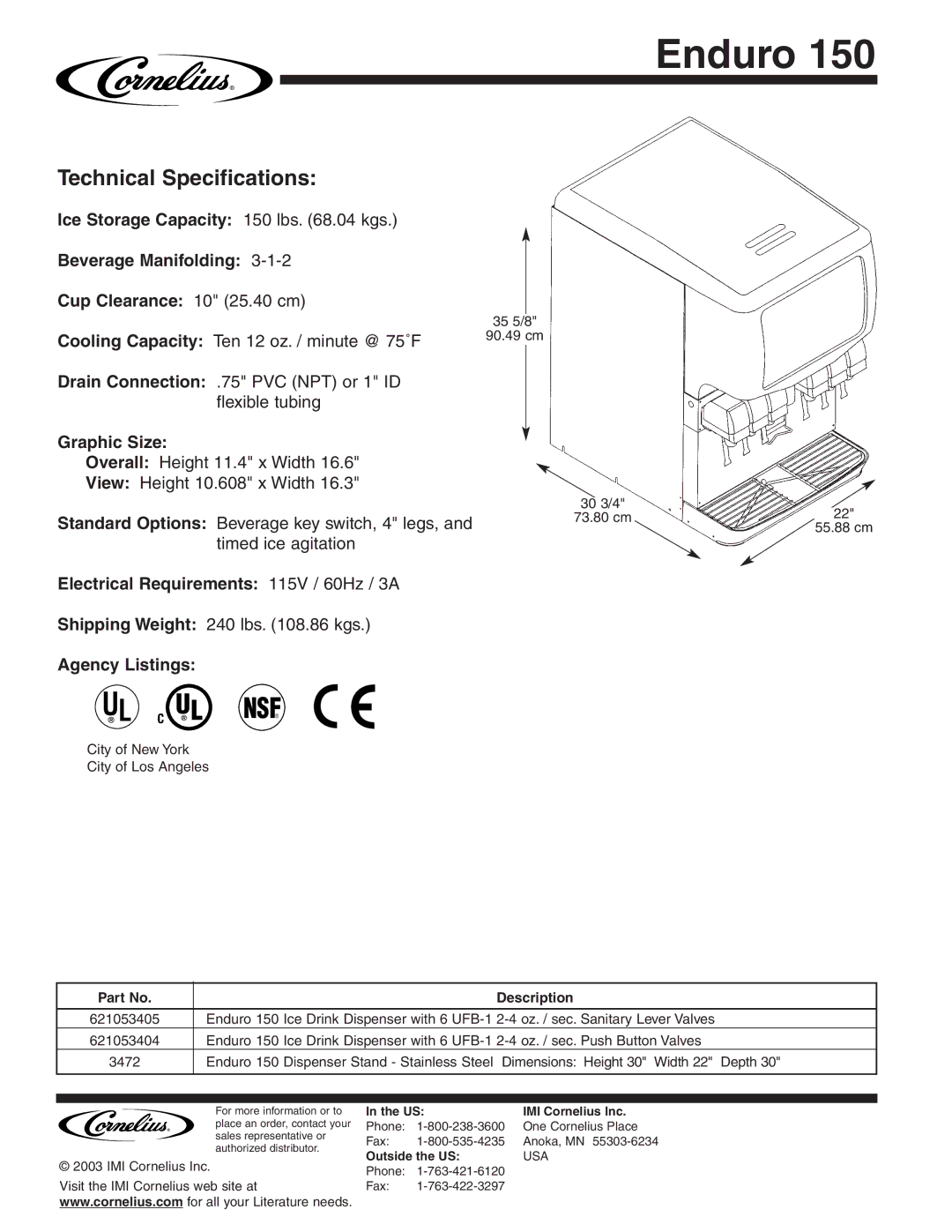

150 specifications

The Cornelius 150 is a revolutionary advancement in the field of automated machinery, designed to enhance productivity and efficiency in various applications. This innovative equipment is engineered with precision and incorporates cutting-edge technologies that streamline operations while ensuring maximum output.One of the standout features of the Cornelius 150 is its advanced automation capabilities. Equipped with a sophisticated control system, the machine can not only perform tasks autonomously but also adapt to changing parameters in real-time. This means operators can input different settings and the Cornelius 150 will adjust its operations accordingly, resulting in optimal performance across a range of scenarios.

The machine also boasts an impressive user interface, designed for ease of use. With an intuitive touchscreen display, operators can monitor processes, receive updates, and make adjustments with minimal effort. This interface allows users of all experience levels to efficiently utilize the machine, reducing the need for extensive training and minimizing the likelihood of operational errors.

In terms of safety features, the Cornelius 150 is equipped with multiple sensors and emergency shutdown mechanisms. These safety attributes ensure that the machine can detect potential hazards and respond swiftly to ensure the safety of the operators and the overall working environment. This emphasis on safety makes the Cornelius 150 a reliable choice for industries where high levels of safety are paramount.

Moreover, the Cornelius 150 utilizes state-of-the-art materials, ensuring durability and longevity. Its robust design minimizes wear and tear, allowing for continuous operation without frequent maintenance. This not only reduces downtime but also lowers operational costs over time.

Another critical characteristic is its energy efficiency. The Cornelius 150 incorporates energy-saving technologies that minimize power consumption, making it an environmentally friendly option. This commitment to sustainability resonates with many businesses today that are striving to reduce their carbon footprint.

In conclusion, the Cornelius 150 is a state-of-the-art machine that offers versatility, advanced automation, and enhanced safety features. With its user-friendly interface, durable construction, and energy-efficient operation, it positions itself as a formidable player in the automated machinery landscape. Businesses investing in the Cornelius 150 can expect improved productivity and reduced operational costs, making it a smart choice for the future.