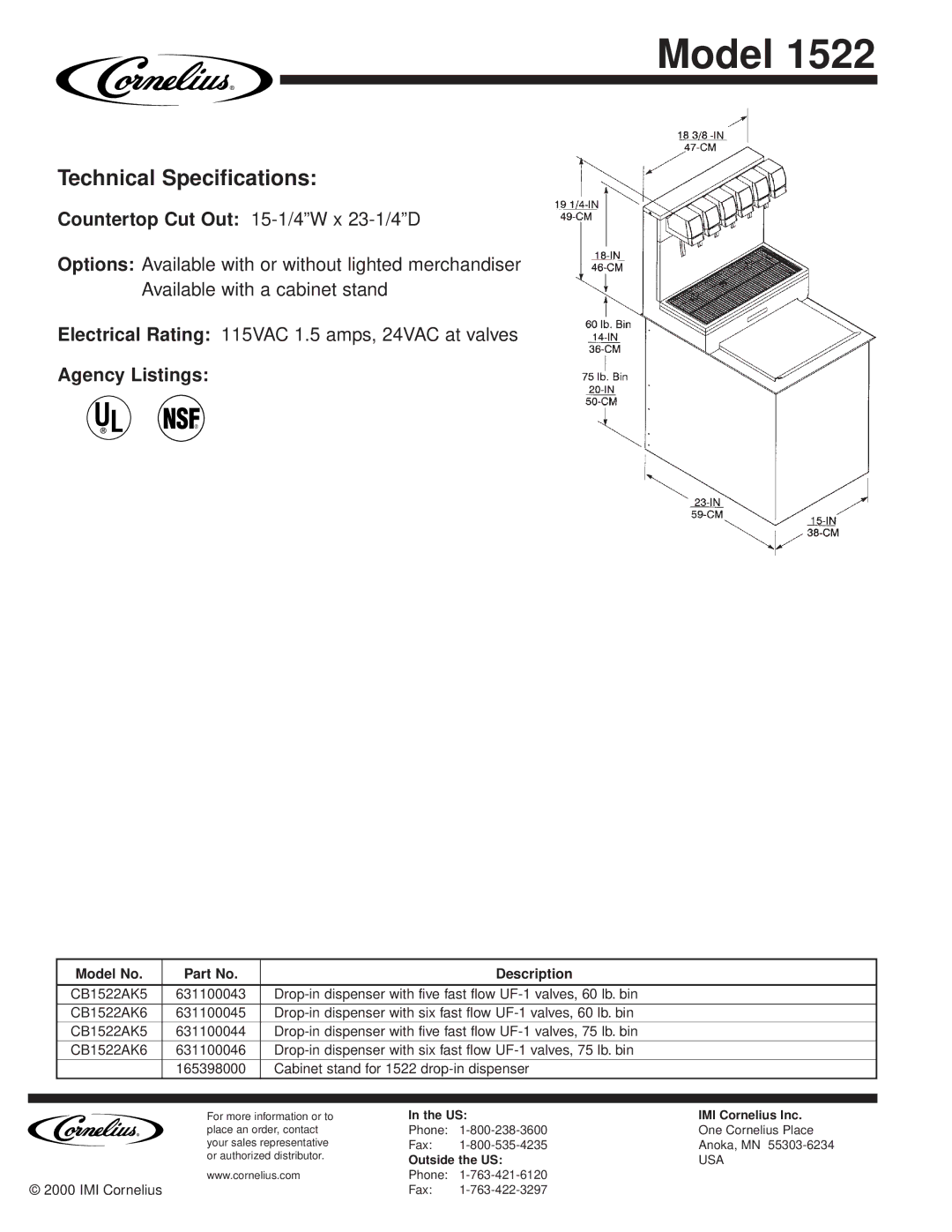

1522 specifications

Cornelius 1522, better known simply as Cornelius, is a significant historical figure in the realm of brewing technology. Established as an advanced brewing system in the early 16th century, it represents a pivotal moment in the evolution of beer brewing, integrating both traditional methods and innovative practices of the time.At its core, Cornelius 1522 is distinguished by its innovative use of fermentation vessels made from stainless steel, a material that significantly enhances the brewing process. These vessels offer a sterile environment, minimizing contamination risks while also making cleaning and maintenance considerably easier than traditional wooden barrels. This technological shift was a game changer, allowing brewers to produce beer with more consistency and quality.

Another notable feature of Cornelius is its focus on temperature control. The system incorporates advanced cooling mechanisms that allow brewers to regulate fermentation temperatures with precision. This control is crucial, as it enables the production of various beer styles, each requiring different fermentation temperatures for optimal flavor profiles. The ability to fine-tune these conditions marked a departure from more rudimentary brewing techniques prevalent during that era.

Moreover, Cornelius 1522 introduced the concept of carbonation control through the use of pressurized tanks. This technology allows for the precise injection of carbon dioxide into the beer, enhancing mouthfeel and overall sensory experience. The result is a beverage that is not only flavorful but also effervescent, appealing to a broader range of consumers.

Aesthetically, the design of Cornelius 1522 reflects its era, merging function with form. Its streamlined vessels feature a polished exterior, representing modernity while adhering to the craftsmanship of the time. The overall setup promotes efficiency, maximizing space while ensuring that the brewing process remains efficient and organized.

In summary, Cornelius 1522 stands as a hallmark of brewing innovation in the 16th century. Its advancements in fermentation technology, temperature control, and carbonation techniques revolutionized the brewing industry. As brewers embraced these new technologies, they set the stage for the modern brewing practices we see today, merging tradition with innovation to produce exceptional beers that continue to capture the imagination and palates of beer lovers worldwide.