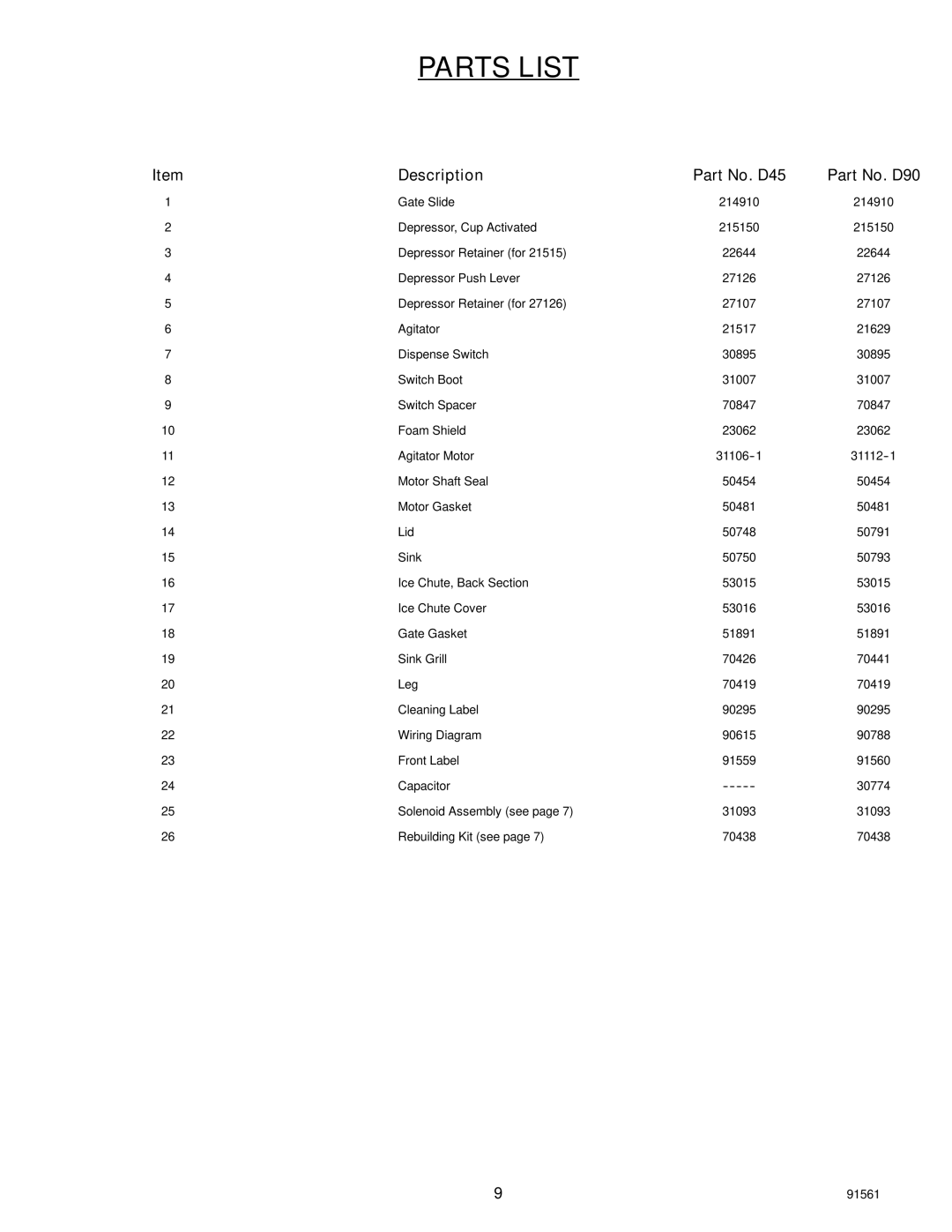

D45, D90 specifications

Cornelius D90 and D45 are advanced dispensing systems designed to meet the needs of a variety of industries, including food service, dairy, and beverage. Both models are renowned for their precision, efficiency, and user-friendly interfaces.The Cornelius D90 is a premium model known for its exceptional performance and versatility. It offers a maximum dispensing capacity of 90 liters per hour, making it ideal for high-demand environments. One of the standout features of the D90 is its adjustable flow rate, which allows operators to customize the dispensing speed based on the product being distributed. This flexibility is particularly beneficial in settings where different beverages or products are dispensed simultaneously.

In terms of technology, the D90 utilizes advanced microprocessor controls that ensure accurate volume dispensation. This reduces waste and enhances productivity. The system is also equipped with a digital display that provides real-time feedback, enabling operators to make quick adjustments as needed. Another key characteristic of the D90 is its compatibility with various product types, including carbonated and non-carbonated beverages, making it a versatile asset in any dispensing environment.

The Cornelius D45, while slightly less advanced than the D90, is an excellent choice for establishments seeking a reliable and efficient dispensing system without the need for high-capacity output. With a dispensing capacity of 45 liters per hour, the D45 is perfect for smaller cafes, bars, and restaurants. It also features adjustable flow rates and is designed for easy operation.

One of the notable characteristics of the D45 is its compact design, which makes it suitable for spaces with limited counter space. The user-friendly interface simplifies operation, ensuring that staff can quickly learn to use the system with minimal training. The D45 also boasts a robust construction, which ensures longevity and durability in demanding environments.

Both models incorporate energy-efficient technologies aimed at reducing power consumption without sacrificing performance. Their innovative designs allow for minimal maintenance and easy cleaning, which is crucial in food and beverage settings.

In summary, the Cornelius D90 and D45 are standout solutions in the dispensing market, offering a range of features tailored to meet the needs of diverse industries. Their combination of performance, flexibility, and ease of use makes them essential tools for any establishment seeking to optimize their beverage dispensing operations. Whether the choice is the high-capacity D90 or the compact D45, both models deliver reliability and quality that operators can depend on.