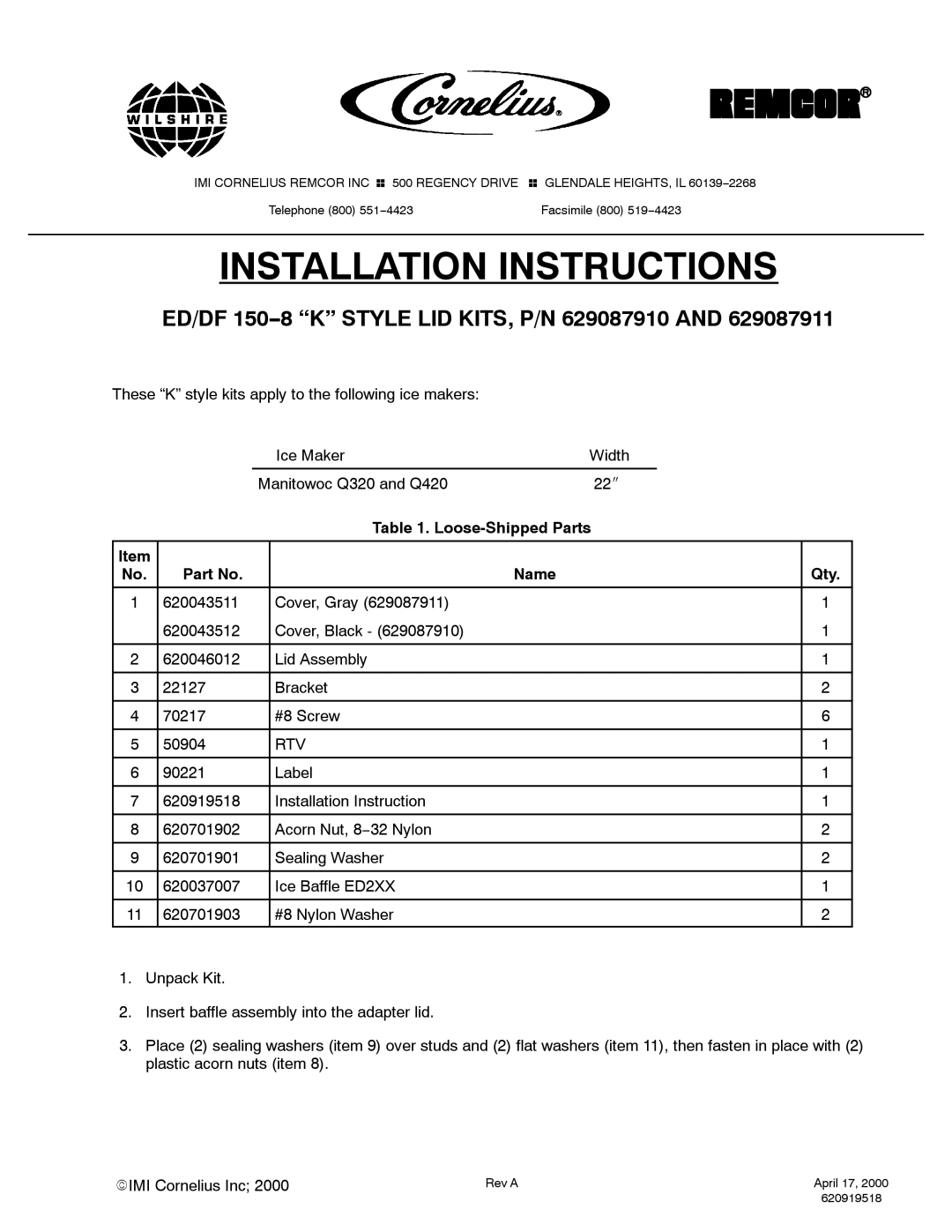

P/N 620046012, P/N 620043511, P/N 620043512, P/N 629087910, P/N 629087911 specifications

Cornelius is a well-respected name in the beverage dispensing industry, with a range of innovative products designed to meet the diverse needs of businesses. Among their offerings are several parts with part numbers 629087911, 629087910, 620043512, 620043511, and 620046012, each designed to optimize performance and enhance efficiency in beverage dispensing systems.The part number 629087911 is known for its durability and is made from robust materials that ensure long-lasting performance. This component typically integrates seamlessly with a variety of beverage dispensers, supporting the delivery of cold drinks with minimal maintenance.

Similarly, part number 629087910 is a complementary component that emphasizes efficiency in cooling. It features advanced cooling technology, ensuring that beverages are chilled quickly without compromising the taste or quality. This model is particularly useful in high-demand settings where rapid service is essential.

The components identified by part numbers 620043512 and 620043511 are specifically designed for soda dispensers. These parts include specialized valves and connectors that facilitate the smooth operation of soda fountains. They are engineered to handle high carbonation pressures and provide consistent beverage flow, which is crucial in preventing any disruptions during service.

Another important part, 620046012, focuses on overall system reliability. This component features an innovative design that minimizes leaks and enhances the seal integrity of the beverage dispensing system. It is crucial for ensuring that the flavors remain intact and that the overall operational cost is kept low due to reduced wastage.

Overall, these Cornelius parts exemplify the brand's commitment to quality and innovation. Each component is crafted with cutting-edge technology to ensure optimal performance and reliability. Their compatibility with multiple beverage dispensing systems allows businesses to mitigate downtime and improve service efficiency. By utilizing these components, operators can achieve better beverage quality, minimize maintenance costs, and enhance customer satisfaction, making these parts invaluable in the fast-paced world of food and beverage service.