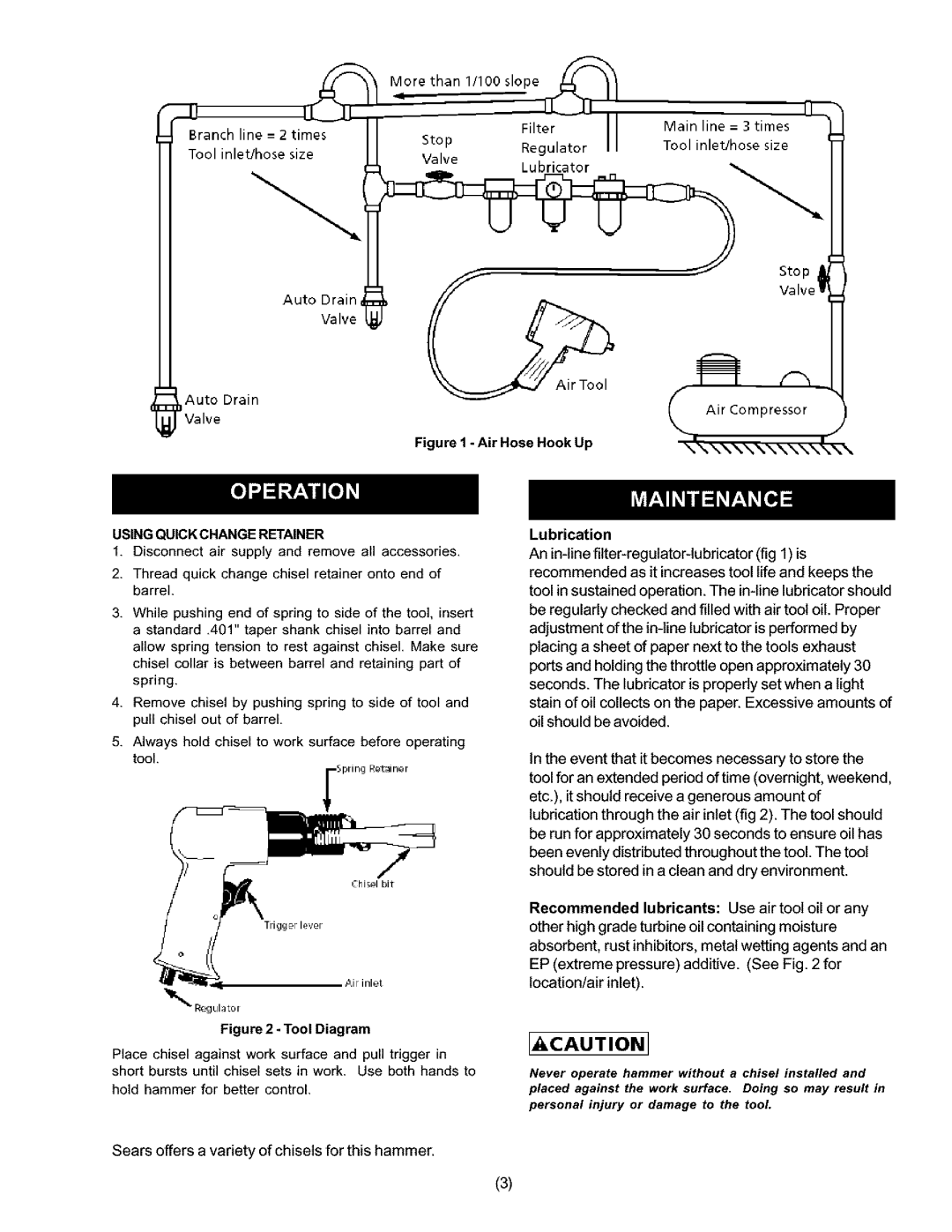

More than 1/100 slope _ _1

Main line = 3 times

_Branch line = 2 times[_ jFilter I Tool inlet/hose size

StopRegulator

Valve Lubricator

I Tool inlet_os_

Stop I

Valve

|

| Air Tool | K% |

i_ | jAute Drain | L | Air |

I_ | Valve | Compressor J | |

| ..\ ..\\..............t...., | ||

|

| Figure 1 * Air Hose Hook Up |

USING QUICK CHANGE RETAINER | Lubrication |

1.Disconnect air supply and remove all accessories.

2.Thread quick change chisel retainer onto end of barrel.

3.While pushing end of spring to side of the tool, insert a standard .401" taper shank chisel into barrel and allow spring tension to rest against chisel. Make sure chisel collar is between barrel and retaining part of spring.

4.Remove chisel by pushing spring to side of tool and pull chisel out of barrel.

5.Always hold chisel to work surface before operating tool.

Spring R_tainer

An

stain of oil collects on the paper. Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for an extended period of time (overnight, weekend, etc.), it should receive a generous amount of lubrication through the air inlet (fig 2). The tool should be run for approximately 30 seconds to ensure oil has been evenly distributed throughout the tool. The tool should be stored in a clean and dry environment.

Trigger lever

Air inlet

_ Regulator

Recommended lubricants: Use air tool oil or any other high grade turbine oil containing moisture absorbent, rust inhibitors, metal wetting agents and an EP (extreme pressure) additive. (See Fig. 2 for location/air inlet).

Figure 2 - Tool Diagram

Place chisel against work surface and pull trigger in short bursts until chisel sets in work. Use both hands to hold hammer for better control.

I,ACAUTION]

Never operate hammer without a chisel installed and

placed against the work surface. Doing so may result in personal injury or damage to the tool.

Sears offers a variety of chisels for this hammer.

(3)