TOCLEANBATTERYAND TERMINALS

Corrosionanddirtonthebatteryandtermi- nalscan causethe batteryto "leak"power. 1_ Removeterminalguard°

2.DisconnectBLACK battery cable first then RED battery cable and remove batteryfrom tractor,

3.Rinsethebatterywithplainwateranddry.

4.Cleanterminalsandbatterycableends with wirebrushuntilbright.

5.Coatterminalswithgreaseorpetroleum jelly.

6.Reinstall battery (See "REPLACING BATTERY'tin the SERVICEAND AD- JUSTMENTSsectionof this manual).

TRANSAXLEMAINTENANCE

Thetransmissionfanandcoolingfinsshould be keptcleanto assurepropercooling.Do notattempttocleanfanortransmissionwhile engineis runningorwhilethe transmission is hot,Topreventpossibledamagetoseals, do notuse highpressurewateror steamto cleantransaxle.

•Inspectcoolingfan to be surefan blades are intactandclean°

•Inspectcoolingfinsfordirt,grassclippings

andothermaterials,Topreventdamageto

seals,do notuse compressedair orhigh pressuresprayerto cleancoolingfins.

TRANSAXLEPUMPFLUID

Thetransaxlewassealedatthefactoryand

fluidmaintenanceis notrequiredfor the life of thetransaxle.Shouldthetransaxleever

leakor requireservicing,contactyournear- est Searsor otherqualifiedservicecenter.

belts if theybeginto slipfromwear,

ENGINE

LUBRICATION

Only use high quality detergent oil rated with API service classification

oil's SAE viscosity grade according to your expected operating temperature.

SAE VISCOSITY GRADES

....... | _ | _ | _ _o | 6_ | B_ | !o_ | ||

O _0 |

| 0 | _O | 20 | _8 | 40 | ||

TEMPERATURE RANGE ANTICIPATED BEFORE NF.3_TOIL CHANGE

NOTE: Although

Check the crankcase oil level before starting the engine and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected before oil change. All oil must meet API service classification

•Be sure tractor is on level surface.

•Oil will drain more freely when warm.

•Catch oil in a suitable container°

1.Remove oil fill cap/dipstick. Be careful not to allow dirt to enter the engine when changing oil.

2.Remove yellow cap from end of drain valve and install the drain tube onto the

fitting.

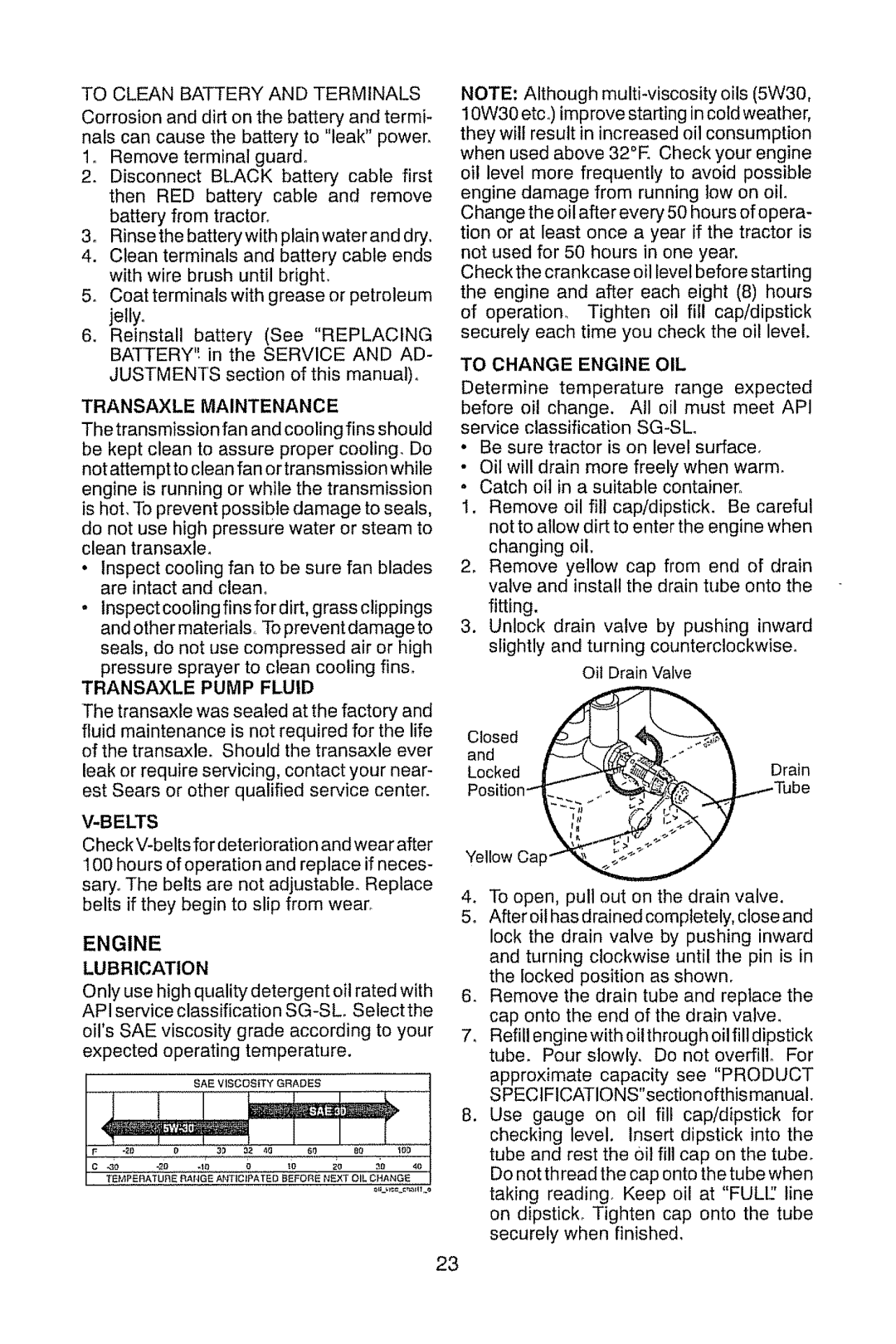

3.Unlock drain valve by pushing inward slightly and turning counterclockwise.

| Oit Drain VaLve |

|

| |

Closed | _ | _ |

|

|

and | ;,>_."_ | "_ |

| |

Locked | ! _ | _ | Drain | |

YellowCapPosition*"_...._..(_i,,',.'___Tube"" ...

4.To open, pull out on the drain valve.

5.After oil has drained completely, close and lock the drain valve by pushing inward and turning clockwise until the pin is in the locked position as shown.

6.Remove the drain tube and replace the

cap onto the end of the drain valve.

7, Refill enginewith oilthrough oilfill dipstick tube. Pour slowly, Do not overfill. For

approximate capacity see "PRODUCT

SPECtFICATIONS"section ofthis manual.

8.Use gauge on oil fill cap/dipstick for checking level. Insert dipstick into the tube and rest the 0i! fill cap on the tube. Do not thread the cap onto the tube when taking reading Keep oil at "FULL.' line on dipstick. Tighten cap onto the tube securely when finished,

23