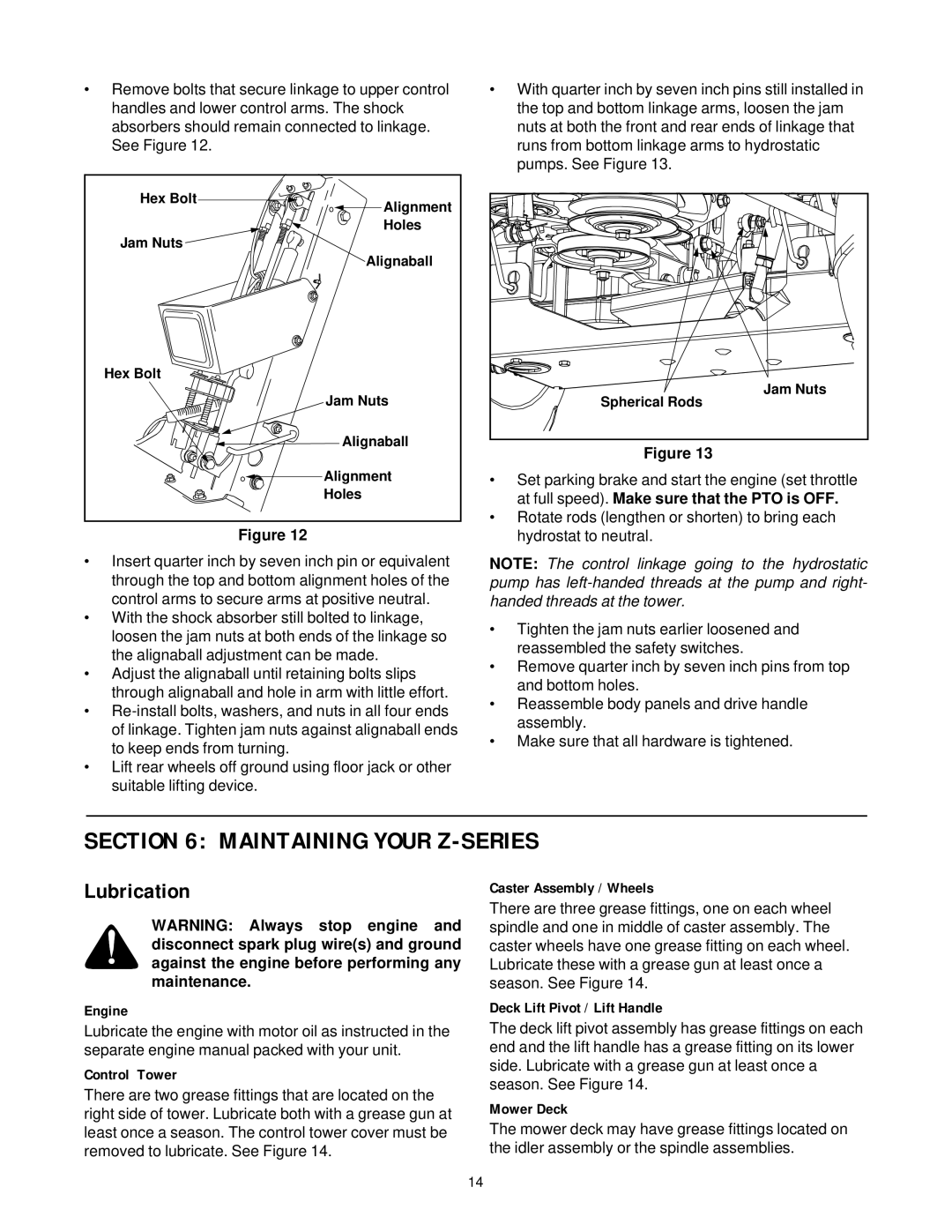

•Remove bolts that secure linkage to upper control handles and lower control arms. The shock absorbers should remain connected to linkage. See Figure 12.

Hex Bolt | Alignment |

| |

| Holes |

Jam Nuts |

|

| Alignaball |

Hex Bolt |

|

| Jam Nuts |

| Alignaball |

| Alignment |

| Holes |

Figure 12

•Insert quarter inch by seven inch pin or equivalent through the top and bottom alignment holes of the control arms to secure arms at positive neutral.

•With the shock absorber still bolted to linkage, loosen the jam nuts at both ends of the linkage so the alignaball adjustment can be made.

•Adjust the alignaball until retaining bolts slips through alignaball and hole in arm with little effort.

•

•Lift rear wheels off ground using floor jack or other suitable lifting device.

•With quarter inch by seven inch pins still installed in the top and bottom linkage arms, loosen the jam nuts at both the front and rear ends of linkage that runs from bottom linkage arms to hydrostatic pumps. See Figure 13.

Jam Nuts |

Spherical Rods |

Figure 13

•Set parking brake and start the engine (set throttle at full speed). Make sure that the PTO is OFF.

•Rotate rods (lengthen or shorten) to bring each hydrostat to neutral.

NOTE: The control linkage going to the hydrostatic pump has

•Tighten the jam nuts earlier loosened and reassembled the safety switches.

•Remove quarter inch by seven inch pins from top and bottom holes.

•Reassemble body panels and drive handle assembly.

•Make sure that all hardware is tightened.

SECTION 6: MAINTAINING YOUR Z-SERIES

Lubrication | Caster Assembly / Wheels |

WARNING: Always stop engine and disconnect spark plug wire(s) and ground against the engine before performing any maintenance.

There are three grease fittings, one on each wheel spindle and one in middle of caster assembly. The caster wheels have one grease fitting on each wheel. Lubricate these with a grease gun at least once a season. See Figure 14.

Engine

Lubricate the engine with motor oil as instructed in the separate engine manual packed with your unit.

Control Tower

There are two grease fittings that are located on the right side of tower. Lubricate both with a grease gun at least once a season. The control tower cover must be removed to lubricate. See Figure 14.

Deck Lift Pivot / Lift Handle

The deck lift pivot assembly has grease fittings on each end and the lift handle has a grease fitting on its lower side. Lubricate with a grease gun at least once a season. See Figure 14.

Mower Deck

The mower deck may have grease fittings located on the idler assembly or the spindle assemblies.

14