SARRI3-S, SARRI1-S, SMRRI3-S, SMRRI1-S, SMRRI2-S specifications

Delfield is a well-respected brand in the commercial refrigeration industry, known for its innovative solutions and high-quality products. Among its range, the stainless steel Refrigerated Salad and Topping Refrigerators, specifically the SSRRI1-S, SSRRI2-S, SSRRI3-S, SMRRI1-S, and SMRRI2-S models, stand out due to their thoughtful design, robust technology, and practical features that cater to the needs of food service operations.The SSRRI1-S is a single-section refrigerated salad unit designed for optimal organization and temperature control. It features a spacious refrigerated compartment, allowing chefs easy access to salad toppings and ingredients. With a user-friendly digital thermostat, operators can maintain precise temperature settings to ensure freshness and safety. The high-efficiency refrigeration system not only keeps the products cold but also minimizes energy consumption, making it an environmentally friendly choice.

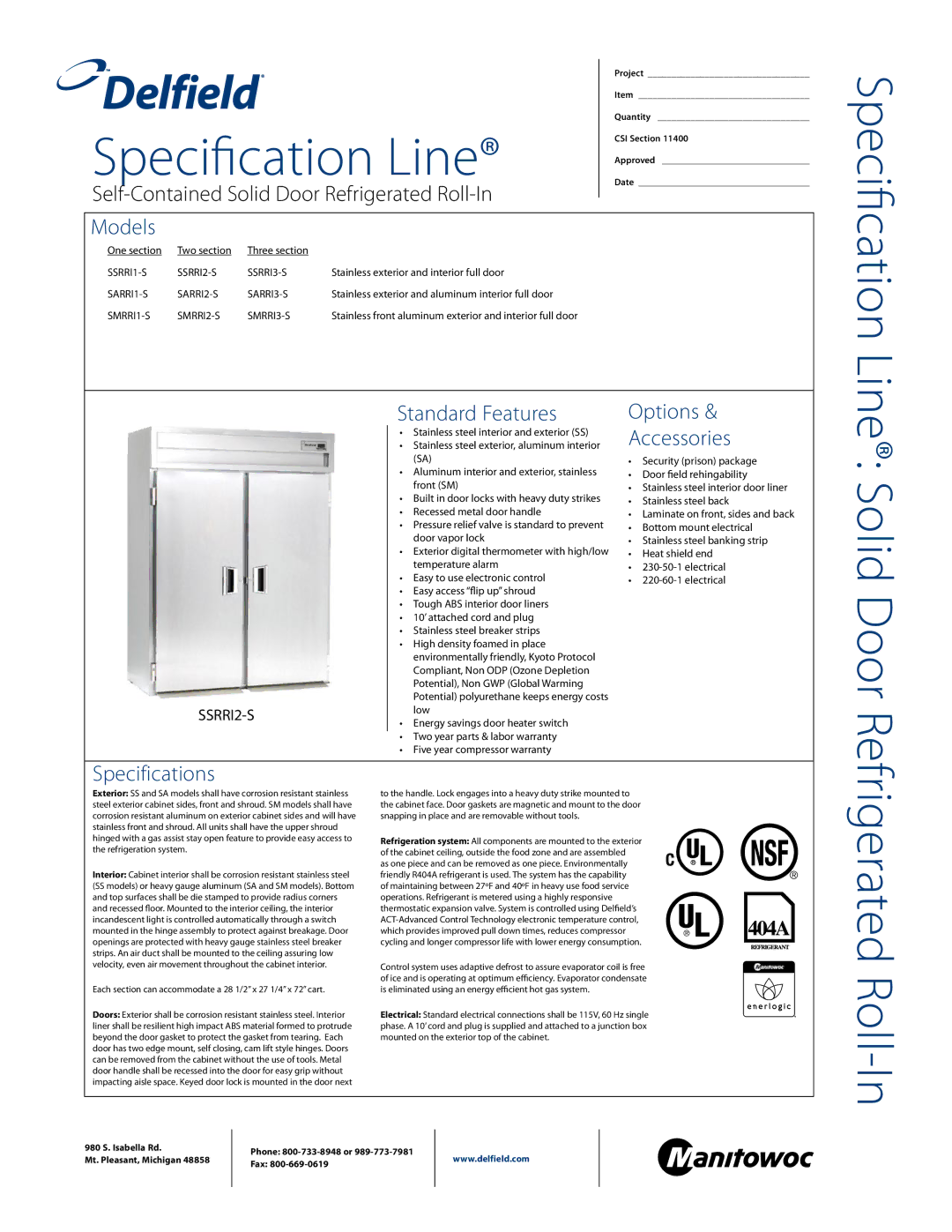

The SSRRI2-S and SSRRI3-S models are two-section and three-section units, respectively, offering additional storage capacity for larger operations. These models share similar high-quality construction, featuring durable stainless steel exteriors that are easy to clean and maintain. The interior is designed with adjustable shelving, maximizing storage versatility and allowing operators to customize the layout according to their needs. Both models are equipped with fluorescent lighting that illuminates the contents, providing visibility and presentation that enhances the appeal of the food items.

On the other hand, the SMRRI1-S and SMRRI2-S units are prep tables that combine storage with a generous work surface. These models come with additional features like large cutting boards and condiment rail inserts, enabling quick and efficient food preparation for salads and sandwiches. The ergonomically designed layout simplifies the workflow for kitchen staff while keeping ingredients organized and within reach.

All five models incorporate advanced refrigeration technologies, promoting consistent temperature control and ensuring that vegetables and toppings stay fresh longer. The easy-access components make maintenance straightforward, allowing operators to focus on food service rather than equipment issues. In summary, Delfield's SSRRI and SMRRI series offer a blend of functionality, durability, and energy efficiency, making them invaluable tools in any commercial kitchen. Their various capacities and features cater to diverse business needs, ensuring that food service operations can deliver high-quality offerings efficiently and reliably.