SST2-S specifications

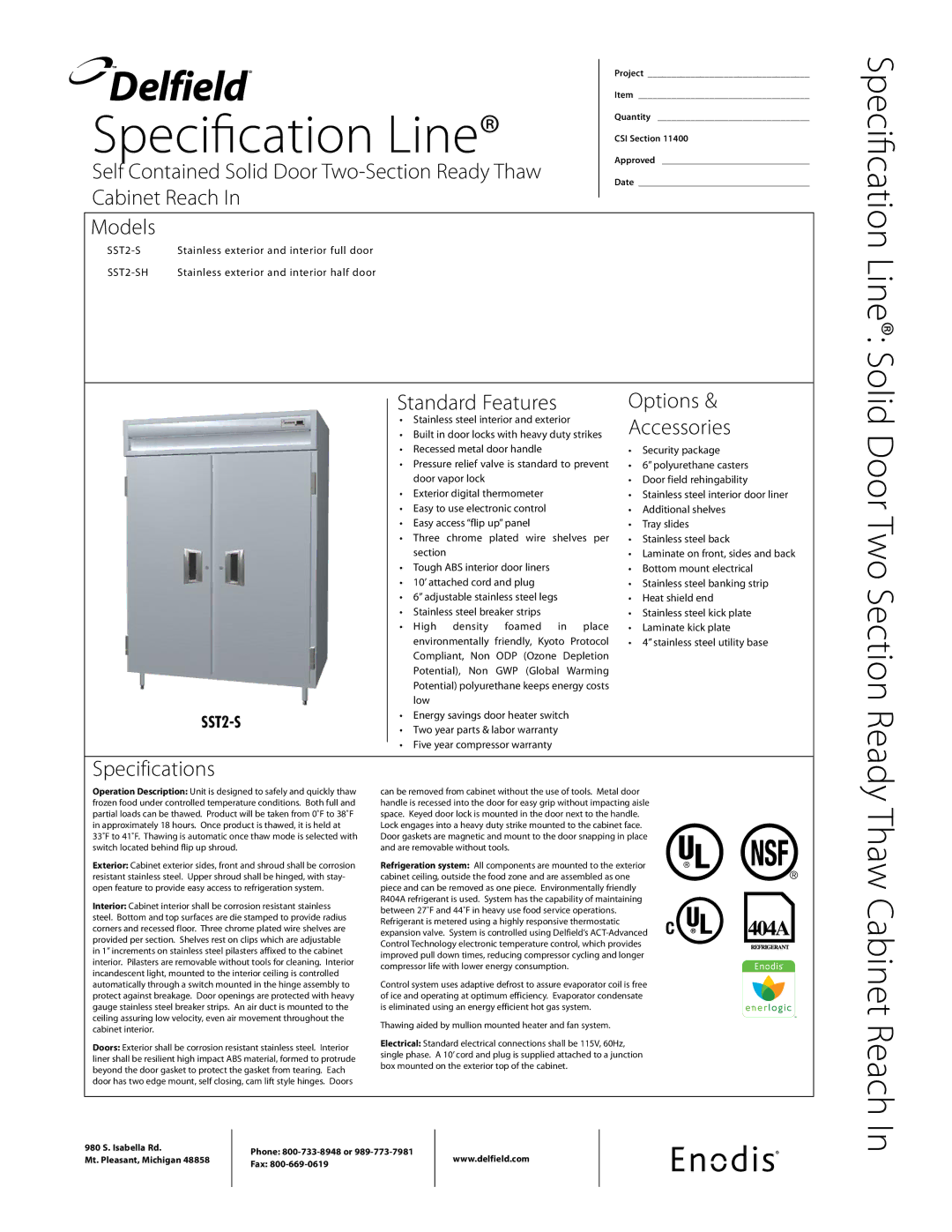

The Delfield SST2-S is a state-of-the-art commercial refrigerator designed to meet the rigorous demands of the foodservice industry. It is highly regarded for its superior performance, energy efficiency, and innovative design, making it an essential asset for restaurants, catering services, and food distribution centers.One of the standout features of the Delfield SST2-S is its robust construction. Built with a stainless steel exterior and an aluminum interior, it is not only durable but also resistant to corrosion and easy to clean. This stainless steel finish gives it a polished and professional appearance, aligning well with the aesthetics of most commercial kitchens.

The SST2-S boasts a generous storage capacity, making it suitable for high-volume operations. Its interior is designed efficiently, offering adjustable shelving to accommodate various food items, from bulk ingredients to prepared meals. This flexibility is crucial for maximizing storage space while ensuring easy access to products.

In terms of temperature control, the Delfield SST2-S utilizes advanced refrigeration technology. Equipped with a precise digital thermostat, it allows operators to set and maintain the ideal temperature for food preservation, which is critical for maintaining freshness and preventing spoilage. The unit operates quietly and efficiently, thanks to its eco-friendly refrigerant, which also contributes to lower energy consumption and reduced operating costs.

Another notable characteristic of this model is its advanced airflow system. The SST2-S features a fan-assisted cooling mechanism that ensures even distribution of cold air throughout the cabinet. This technology prevents hot spots and maintains uniform temperatures, ensuring that all food items are kept at optimal conditions.

The accessibility of the Delfield SST2-S is further highlighted by its easy-to-use design. It includes self-closing doors that seal tightly to maintain temperature, minimizing energy loss. The ergonomic handle design allows for easy opening even in busy kitchen environments.

Overall, the Delfield SST2-S combines durability, efficiency, and advanced technology, making it a top choice for those in the foodservice industry seeking reliable refrigeration solutions. Its spacious interior, excellent temperature control, and user-friendly features position it as a crucial component for operations that prioritize quality and safety in food storage.