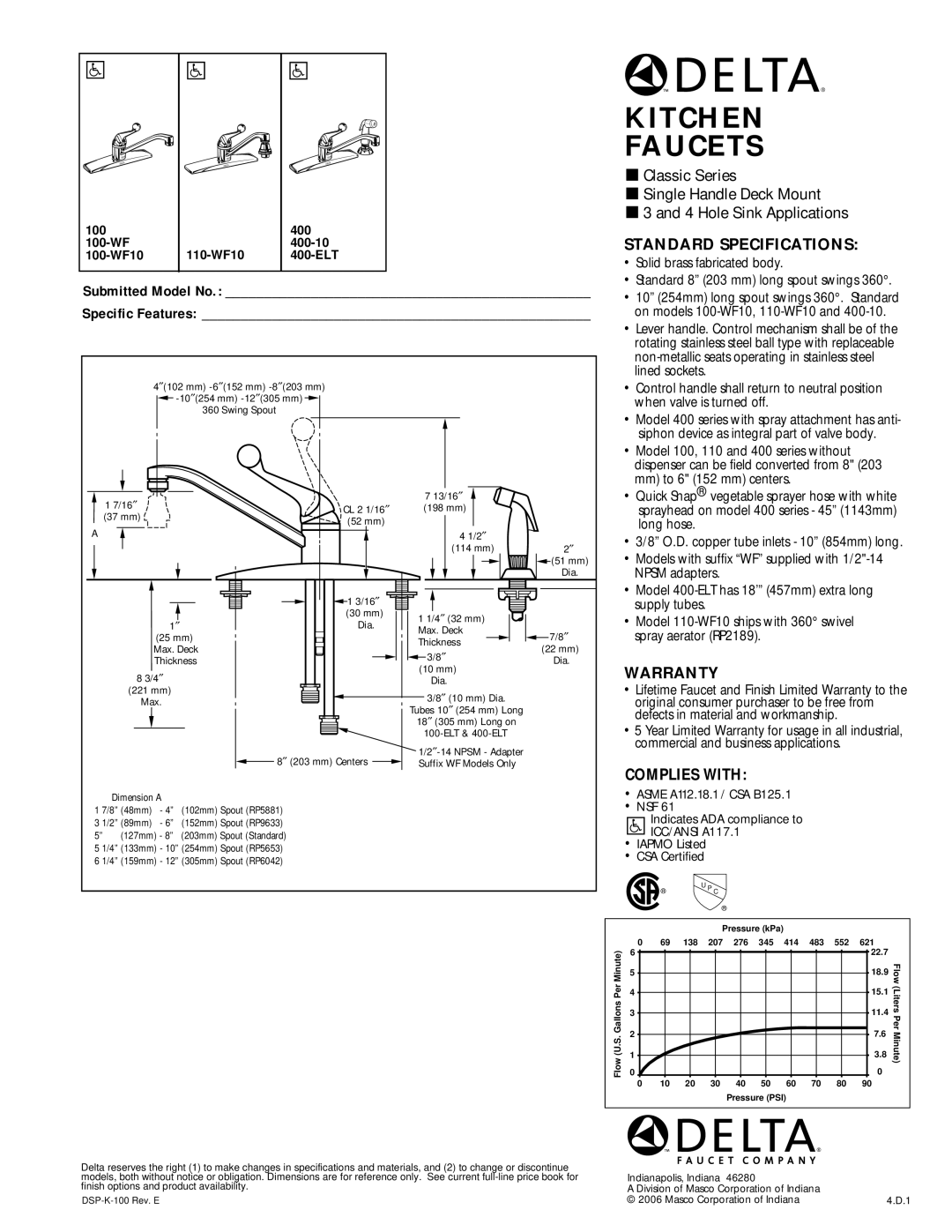

400-ELT, 400-10, 110-WF10, 100-WF, 100-WF-10 specifications

The Delta 400-10,100-WF,110-WF10,100-WF-10,400-ELT is an advanced electronic load tester designed for the rigorous demands of modern testing environments. With a range of features and technologies that enhance its functionality, this model stands out as a crucial tool for engineers and technicians working with various electronic devices and systems.One of the primary features of the Delta 400 series is its capability to simulate a wide range of load conditions. This allows users to test power sources, batteries, and other electronic components under realistic operational scenarios. The ability to adjust load settings swiftly and accurately means that engineers can evaluate the performance and stability of their systems under different environments. The integration of both constant current (CC) and constant voltage (CV) modes provides versatility, ensuring that the tester can handle a broad spectrum of testing requirements.

The model is equipped with advanced digital technology, including a high-resolution display that provides real-time data visualization. This feature allows users to monitor voltage, current, power, and resistance metrics at a glance, facilitating easier analysis. Automated testing routines can also be programmed, which enhances efficiency and reduces manual oversight during testing cycles.

Durability is another cornerstone of the Delta 400-10,100-WF's design. Constructed using robust materials, the unit is built to withstand the rigors of frequent use in both laboratory and field settings. It also includes protection features against overcurrent, overvoltage, and overheating, which guarantees the safety of both the tester and the devices under test.

The product also integrates communication technologies such as USB, GPIB, and LAN interfaces, allowing seamless integration into automated testing environments. This ensures that data can be easily transferred to external devices for further analysis or record-keeping.

In conclusion, the Delta 400-10,100-WF,110-WF10,100-WF-10,400-ELT is a superior electronic load tester that combines high-performance capabilities, user-friendly interfaces, and robust construction. Its multitude of features positions it as an essential asset for anyone involved in the testing and quality assurance of electronic components and systems.