ASSEMBLY (does not apply to all units)

Assembly for "Tank" units

The wheels and handle do not provide adequate clearance, stability or support for pulling the unit up and

down stairs or steps. The unit must be lifted, or pushed up a ramp.

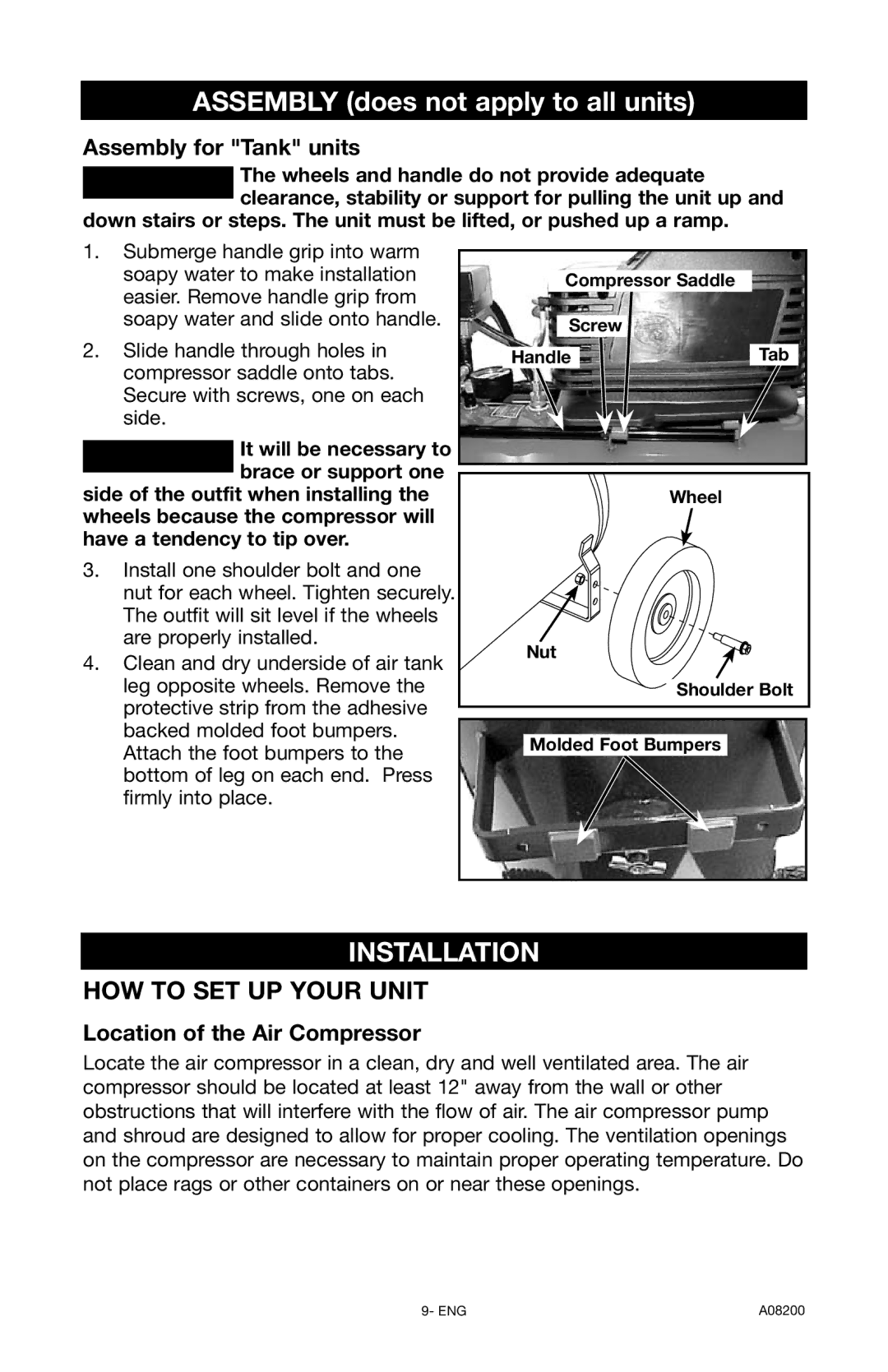

1.Submerge handle grip into warm soapy water to make installation easier. Remove handle grip from soapy water and slide onto handle.

2.Slide handle through holes in compressor saddle onto tabs. Secure with screws, one on each side.

Compressor Saddle Screw

Handle

Tab

It will be necessary to |

| |

brace or support one |

| |

side of the outfit when installing the | Wheel | |

wheels because the compressor will |

| |

have a tendency to tip over. |

| |

3. Install one shoulder bolt and one |

| |

nut for each wheel. Tighten securely. |

| |

The outfit will sit level if the wheels |

| |

are properly installed. | Nut | |

4. Clean and dry underside of air tank | ||

| ||

leg opposite wheels. Remove the | Shoulder Bolt | |

protective strip from the adhesive |

| |

backed molded foot bumpers. | Molded Foot Bumpers | |

Attach the foot bumpers to the | ||

| ||

bottom of leg on each end. Press |

| |

firmly into place. |

|

INSTALLATION

HOW TO SET UP YOUR UNIT

Location of the Air Compressor

Locate the air compressor in a clean, dry and well ventilated area. The air compressor should be located at least 12" away from the wall or other obstructions that will interfere with the flow of air. The air compressor pump and shroud are designed to allow for proper cooling. The ventilation openings on the compressor are necessary to maintain proper operating temperature. Do not place rags or other containers on or near these openings.

9- ENG | A08200 |