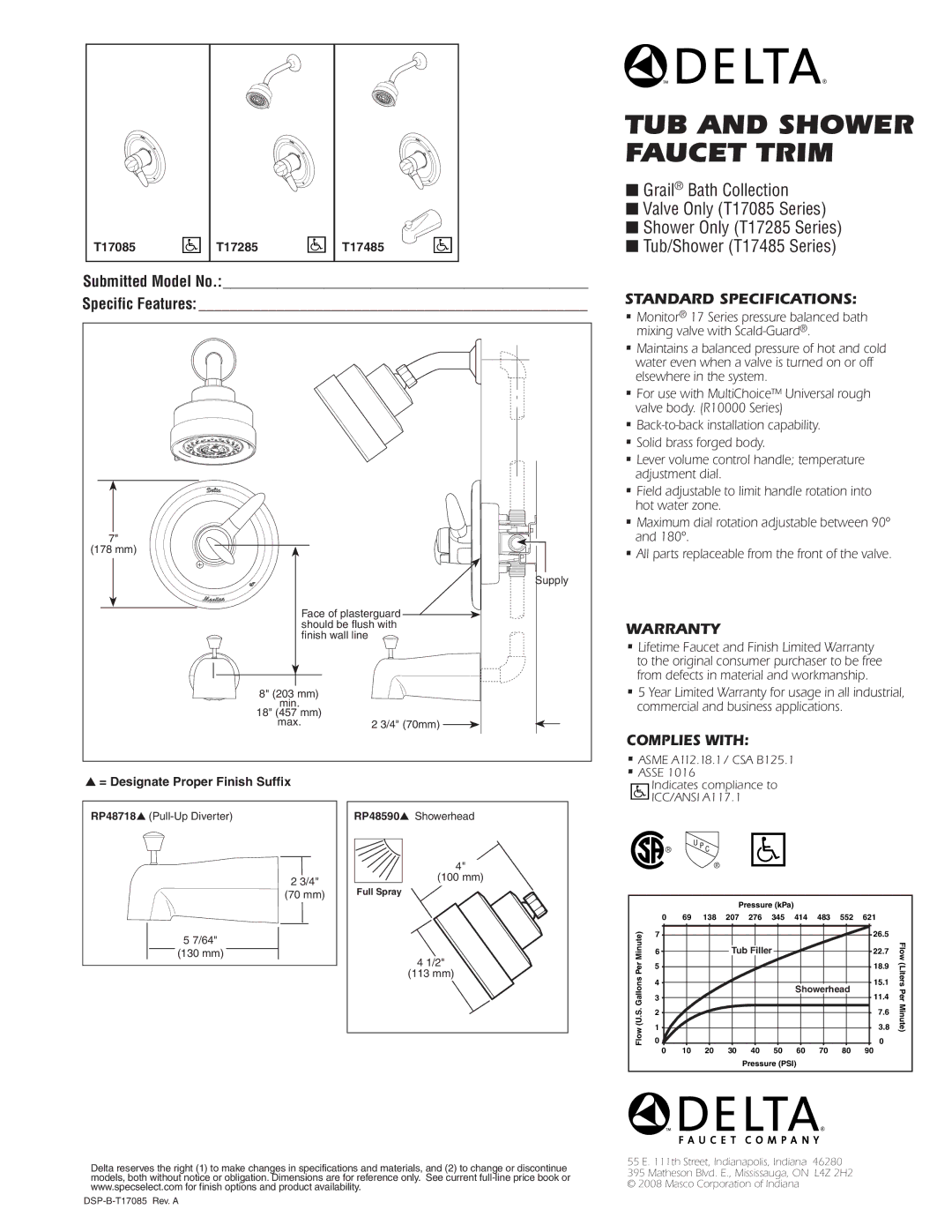

T17485, T17085, T17285 specifications

The Delta T17285, T17085, and T17485 designate a series of high-performance computer numerically controlled (CNC) lathes specifically designed for precision machining applications in various industries. These models stand out due to their cutting-edge technologies, versatile features, and robust characteristics, catering to professionals seeking efficiency and accuracy in their production processes.One prominent feature of the Delta T17285 is its exceptional spindle speed range, allowing for rapid and effective material removal. This lathe is engineered with a powerful motor that provides consistent torque, making it suitable for processing a wide range of materials, including metals and plastics. The precision of the T17285 is further enhanced by its rigid frame and high-quality linear guides, minimizing vibrations during operation and ensuring tight tolerances.

Similarly, the Delta T17085 is equipped with advanced digital servo motors that contribute to its high-speed capabilities. The machine features a user-friendly interface, allowing operators to easily program and adjust parameters for optimal performance. This flexibility is a key advantage, making the T17085 suitable for both small-batch production and larger manufacturing runs. Additionally, the lathe incorporates an automatic tool changer, which significantly reduces downtime and enhances productivity.

The Delta T17485, on the other hand, offers an expanded capacity that caters to larger workpieces. It combines a robust bed design with a powerful spindle that can accommodate heavier loads and more extensive operations. This machine is ideal for industries requiring large components, such as aerospace and automotive sectors. Furthermore, the T17485 incorporates intelligent technology that allows for real-time monitoring of machining processes, which helps in enhancing operational efficiency and reducing scrap rates.

Overall, the Delta T17285, T17085, and T17485 series exhibit a harmony of innovation and reliability, integrating advanced CNC technologies with user-centric features. This combination ensures that operators can achieve precision machining with enhanced productivity across diverse applications. Whether for complex part production or straightforward tasks, these models provide a versatile solution that meets the demands of modern manufacturing environments. Their commitment to quality and performance secures Delta’s position as a competitive player in the CNC lathe market.