DVPDU-01 specifications

Delta Electronics is renowned for its innovative solutions in automation and control, and one of its standout products is the DVPDU-01. This versatile module is part of Delta's DVP series, designed to enhance the capabilities of Delta's Programmable Logic Controllers (PLCs).The DVPDU-01 module serves as a communication interface that facilitates seamless integration and interaction between various devices and machines in an industrial environment. One of the primary features of this product is its support for advanced communication protocols, including Modbus and CANopen. This enables users to connect the DVP series PLCs with a broad range of devices, such as sensors, actuators, and other PLCs, promoting a cohesive automation architecture.

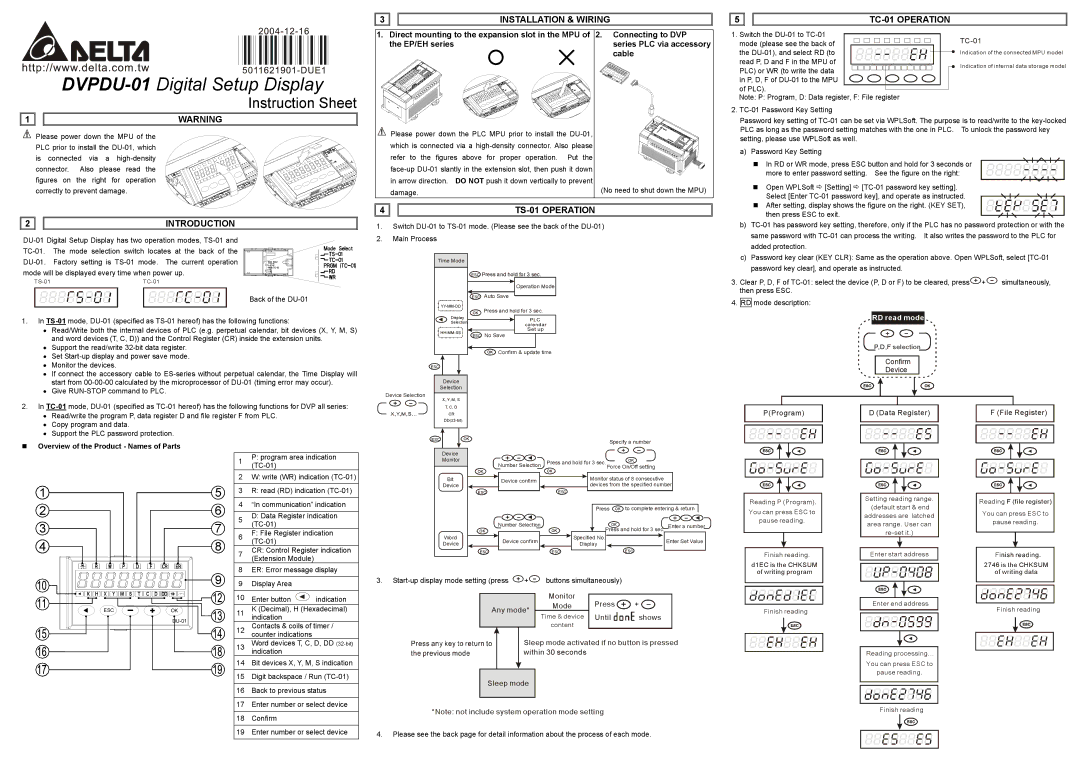

Another notable characteristic of the DVPDU-01 is its compact design, which allows for easy installation in confined spaces while maintaining high performance. The module features a user-friendly LED indicator that provides real-time status updates, ensuring that users can monitor the operational performance without extensive configuration.

In terms of technology, the DVPDU-01 leverages Delta's cutting-edge automation technology, ensuring high-speed data transmission and reliability. This is crucial in environments where timely decision-making is essential for operational efficiency. The module supports multiple I/O points, which expands the scalability of control systems, making it an ideal choice for applications ranging from simple processes to complex industrial automation.

The DVPDU-01 is also engineered with robust protective features, including overcurrent and overload protection. This ensures the longevity of the component and reduces downtime, a vital aspect for industries that operate under continuous production schedules.

Moreover, the module is compatible with Delta's software platforms, facilitating simplified programming and configuration. Users can easily set parameters and monitor performance through Delta's intuitive software tools, making it accessible for both experienced engineers and those new to automation technologies.

In conclusion, the Delta Electronics DVPDU-01 is a powerful communication module that significantly enhances the functionality of Delta's PLCs. With its advanced communication protocols, compact design, reliability, and user-friendly features, it stands out as an essential component for modern industrial automation systems, meeting the needs of diverse applications across various sectors.