ZElectrical Specifications

Specifications |

| |

Display | Monochromatic STN LCD | |

Effective Display Area | (W) x (H) = 72 x 22 (unit: mm) | |

Display Resolution | 160×32: ASCII: 5×8, 8×8, 8×12, 8×16 | |

LCD Contrast Adjustment | Set by Software, adjust the contrast by the press button in the function table | |

LCD Backlight Type | LED Backlight: Automatic | |

Function / Numeric Keys | F0 / 0 ~ F9 / 9, ESC, ENTER and Arrow Keys | |

External Input Power | 24V (3W Max.) | |

Memory Capacity | 256K Byte | |

CPU | Hitachi HD64F3064F | |

RAM of System | 32K Byte | |

Communication Interface | COM1: | |

Waterproof Class of Front | IP65 / NEMA4 | |

Panel | ||

| ||

Operating Temperature for | 0 ~ 50°C; 20 ~ 90﹪RH | |

Hardware | ||

| ||

Storage Temperature for |

| |

Hardware | ||

| ||

Vibration | 5Hz≦f<9Hz = Continuous: 1.75mm / Occasional: 3.5mm | |

9Hz≦f≦150Hz = Continuous: 0.5g / Occasional: 1.0g | ||

| ||

Shock | 15g peak, 11ms duration, | |

on 3 mutually perpendicular axes (total of 18 shocks) | ||

| ||

Radiated Emission | CISPR11, Class A | |

Electrostatic Discharge | ||

Immunity | ||

| ||

Radiated Immunity | ||

Electrical Fast Transient | ||

Weight / Dimensions | 0.24kg; 147×97×35.5mm (Width(W) × Height(H) × Deep(D)) | |

Cooling Method | Natural Air Cooling |

[Program Copy Card

TP02 series provides Program Copy Card Function to copy user program, system function and passwords that is different from the copy program. It is used to copy the whole HMI environment settings and application programs to another HMI rapidly. Using Program Copy Card saves time and manpower. The operation is as follows.

Definition: Program Copy Card → PCC, TP Series → TP

| (TP→PCC) | (PCC→TP) | |

Step 1 | Turn the switch on the PCC to TP ÆPCC | Turn the switch on the PCC to PCCÆTP | |

Step 2 | Insert the PCC into the extension slot of TP | Insert the PCC into the extension slot of TP | |

Step 3 | Input the power to TP | Input the power to TP | |

Step 4 | It will display “remove PCC” on the screen and | It will display “remove PCC” on the screen and | |

power on again. | power on again. | ||

| |||

HMI Display Message |

| ||

|

|

| |

| (TP→PCC) | (PCC→TP) | |

| If the TP model type does not correspond with the | If there is no program in PCC, TP will display “The | |

Step 1 | model type of program of PCC, TP will display “TP | PCC is Empty. PCC→TP series is illegal”. | |

series and PCC is different. Press Enter to |

| ||

|

| ||

| Confirm TP series→PCC. Press Esc to Exit”. |

| |

Step 2 | TP will display “TP→PCC series Please wait!” | TP will display “PCC→TP series Please wait!” | |

during transmission. | during transmission. | ||

| |||

Step 3 | TP will display “Please Remove the PCC and | TP will display “Please Remove the PCC and | |

Reboot” when transmission is completed. | Reboot” when transmission is completed. | ||

| |||

\Password Function

If the user forgot the password, the password can be cleared by using the following code: 8888. This universal code will clear the password and all TP02 series internal programs. The TP02 series will be reset to the factory settings by using this code also. Please pay close attention when using it.

The password can be the alphabet from A to Z or the number from 0 to 9. But it must use the function keys F0 ~ F9 to input the password characters. Please refer to the following table.

| Function Key |

|

| Use Method |

|

| Function Key |

|

| Use Method |

| F0 |

|

| scrolls in a loop as follows |

|

| F5 |

|

| It just can be used to be constant 5. |

|

|

| 0→A→B→C→D→E→F→0 |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

| F1 |

|

| scrolls in a loop as follows |

|

| F6 |

|

| It just can be used to be constant 6. |

|

|

| 1→G→H→I→J→K→1 |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

| F2 |

|

| scrolls in a loop as follows |

|

| F7 |

|

| It just can be used to be constant 7. |

|

|

| 2→L→M→N→O→P→2 |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

| F3 |

|

| scrolls in a loop as follows |

|

| F8 |

|

| It just can be used to be constant 8. |

|

|

| 3→Q→R→S→T→U→ V→3 |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |

| F4 |

|

| scrolls in a loop as follows |

|

| F9 |

|

| It just can be used to be constant 9. |

|

|

| 4→W→X→Y→Z→4 |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

]Hardware Operation

When the user wants to startup TP02 series, a 24VDC power is needed. After applying 24VDC power to TP02 series, it will enter into the startup display and then enter the

SELECTIONS |

|

| EXPLANAION | ||

|

| Use the connection cable (DVPACAB530) to connect the TP02 serial communication | |||

Download Program |

| port | |||

|

| program to TP02. | |||

|

| Use the connection cable (DVPACAB530) to connect the TP02 serial communication | |||

Upload Program |

| port | |||

|

| program from TP02. | |||

|

| Transfer a program between two TP02 units. | |||

|

| 1: transmit programs | |||

Copy Program |

| 2: receive programs | |||

| When transmit programs and data between two TP02 units. Set one TP02 to | ||||

|

| ||||

|

| “Receive Program” mode and the other TP02 to “Transmit Program” mode. Please | |||

|

| use twisted pair wires to connect the two units via the | |||

|

| There are 8 items that used to modify TP02 system settings: | |||

|

| 1. | Communication protocol: Setting the address of TP02, the control port of PLC, | ||

|

|

| and the communication string for either | ||

|

| 2. | Contrast: Adjust the contrast of LCM display screen. | ||

|

| 3. | |||

|

|

| minutes. If set to 00, the LCM | ||

|

| 4. | Buzzer: Used to set the buzzer sound, normal mode or quiet mode. | ||

TP02 Settings |

| 5. | Language Setting: Used to set the displayed language. English, Traditional | ||

|

| Chinese, Simplified Chinese or user defined language. | |||

|

|

| |||

|

| 6. | Password setting: Used to set, enable, and disable the password function. If the | ||

|

|

| password function is enabled, it will require the user to input a password before | ||

|

|

| entering any system menu. The factory password is | 1234 | . |

|

| 7. | Startup display: Used to select the TP02 startup display. User can select “user | ||

|

|

| defined” to use the file that designed by TPEdit and download to TP02. | ||

|

| 8. | Comm. indicator: The user can determine if the | ||

|

|

| blink or not during communication. | ||

|

| There are two methods to connect to PLC: | |||

|

| 1. | Using TP02 serial communication port (COM1) | ||

|

|

| |||

PLC Connection |

|

| program communication I/O | ||

|

| 2. | Using extension communication port (COM2) | ||

|

|

| |||

|

|

| port to | ||

|

| Execute the internal program that download from TPEdit or transmitted from other | |||

Execution |

| TP02 units. When program is in execution, the user can return to system menu by | |||

|

| pressing Escape / Exit (Esc) key for 5 seconds. | |||

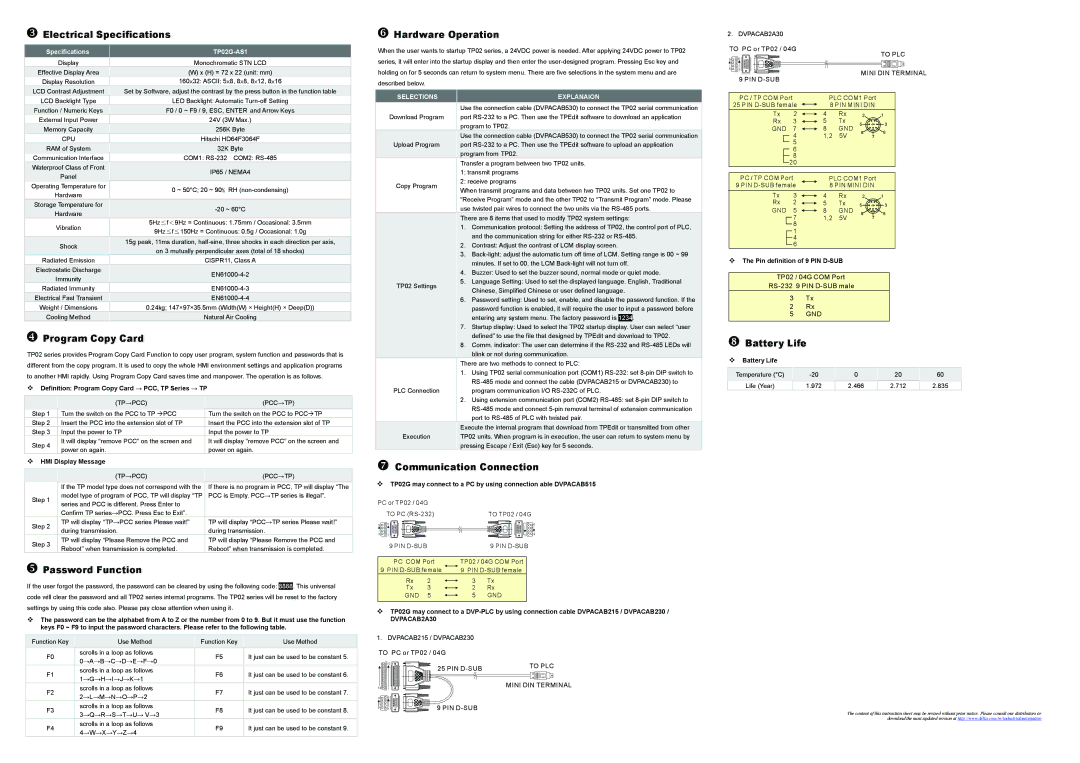

^Communication Connection

TP02G may connect to a PC by using connection able DVPACAB515

PC or TP02 / 04G |

|

|

| ||

| TO PC |

| TO TP02 / 04G |

| |

9 | 5 |

|

| 1 | 6 |

6 | 1 |

|

| 5 | 9 |

| 9 PIN |

|

| 9 PIN |

|

| PC COM Port | TP02 / 04G COM Port |

| ||

| 9 PIN | 9 PIN |

| ||

| Rx | 2 | 3 | Tx |

|

| Tx | 3 | 2 | Rx |

|

| GND | 5 | 5 | GND |

|

TP02G may connect to a

1. DVPACAB215 / DVPACAB230

TO PC or TP02 / 04G

| 13 | 25 PIN | TO PLC |

|

| ||

|

|

| |

14 | 1 |

| MINI DIN TERMINAL |

9 | 5 |

|

|

6 | 1 | 9 PIN |

|

2. DVPACAB2A30

TO PC or TP02 / 04G |

|

|

|

| TO PLC | ||

9 | 5 |

|

|

|

|

| |

|

|

|

|

|

| ||

6 | 1 |

|

|

| MINI DIN TERMINAL | ||

| 9 PIN |

|

|

| |||

|

|

|

|

|

|

| |

| PC / TP COM Port |

| PLC COM1 Port |

| |||

| 25 PIN | 8 PIN MINI DIN |

| ||||

| Tx | 2 | 4 | Rx | 2 |

| 1 |

| Rx | 3 | 5 | Tx | 5 | 4 | 3 |

| GND | 7 | 8 | GND | |||

| 8 |

| 6 | ||||

|

| 4 | 1,2 | 5V | 7 | ||

|

|

|

| ||||

|

| 5 |

|

|

|

|

|

|

| 6 |

|

|

|

|

|

|

| 8 |

|

|

|

|

|

| 20 |

|

|

|

|

| |

| PC / TP COM Port |

| PLC COM1 Port |

| |||

| 9 PIN | 8 PIN MINI DIN |

| ||||

| Tx | 3 | 4 | Rx | 2 |

| 1 |

| Rx | 2 | 5 | Tx | 5 | 4 | 3 |

| GND | 5 | 8 | GND | 8 |

| 6 |

|

| 7 | 1,2 | 5V | 7 | ||

|

|

|

| ||||

|

| 8 |

|

|

|

|

|

|

| 1 |

|

|

|

|

|

|

| 4 |

|

|

|

|

|

|

| 6 |

|

|

|

|

|

The Pin definition of 9 PIN

TP02 / 04G COM Port

3 Tx

2Rx

5GND

_Battery Life

Battery Life

Temperature (°C) |

|

| 0 |

| 20 |

| 60 | |

Life (Year) |

| 1.972 |

| 2.466 |

| 2.712 |

| 2.835 |

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most updated version at http://www.delta.com.tw/industrialautomation