TROUBLESHOOTING

27

TROUBLESHOOTING

Continued

![]() WARNING: If you smell gas

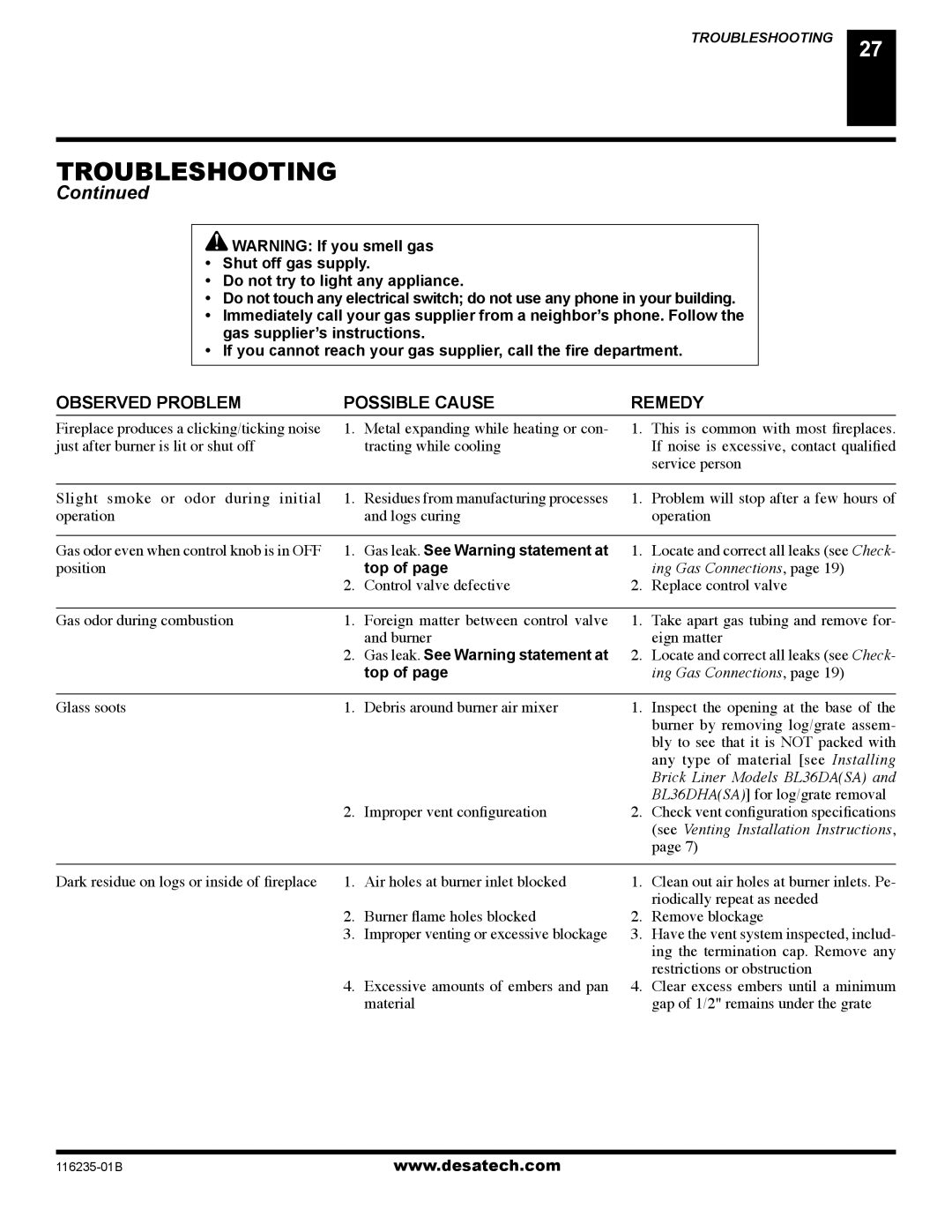

WARNING: If you smell gas

•Shut off gas supply.

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department.

OBSERVED PROBLEM | POSSIBLE CAUSE | REMEDY | ||

|

|

|

|

|

Fireplace produces a clicking/ticking noise | 1. | Metal expanding while heating or con- | 1. | This is common with most fireplaces. |

just after burner is lit or shut off |

| tracting while cooling |

| If noise is excessive, contact qualified |

|

|

|

| service person |

|

|

|

|

|

Slight smoke or odor during initial | 1. | Residues from manufacturing processes | 1. | Problem will stop after a few hours of |

operation |

| and logs curing |

| operation |

|

|

|

|

|

Gas odor even when control knob is in OFF | 1. | Gas leak. See Warning statement at | 1. | Locate and correct all leaks (see Check- |

position |

| top of page |

| ing Gas Connections, page 19) |

| 2. | Control valve defective | 2. | Replace control valve |

|

|

|

|

|

Gas odor during combustion | 1. | Foreign matter between control valve | 1. | Take apart gas tubing and remove for- |

|

| and burner |

| eign matter |

| 2. | Gas leak. See Warning statement at | 2. | Locate and correct all leaks (see Check- |

|

| top of page |

| ing Gas Connections, page 19) |

|

|

|

|

|

Glass soots | 1. | Debris around burner air mixer | 1. | Inspect the opening at the base of the |

|

|

|

| burner by removing log/grate assem- |

|

|

|

| bly to see that it is NOT packed with |

|

|

|

| any type of material [see Installing |

|

|

|

| Brick Liner Models BL36DA(SA) and |

|

|

|

| BL36DHA(SA)] for log/grate removal |

| 2. | Improper vent configureation | 2. | Check vent configuration specifications |

|

|

|

| (see Venting Installation Instructions, |

|

|

|

| page 7) |

|

|

|

|

|

Dark residue on logs or inside of fireplace | 1. | Air holes at burner inlet blocked | 1. | Clean out air holes at burner inlets. Pe- |

|

|

|

| riodically repeat as needed |

| 2. | Burner flame holes blocked | 2. | Remove blockage |

| 3. | Improper venting or excessive blockage | 3. | Have the vent system inspected, includ- |

|

|

|

| ing the termination cap. Remove any |

|

|

|

| restrictions or obstruction |

| 4. | Excessive amounts of embers and pan | 4. | Clear excess embers until a minimum |

|

| material |

| gap of 1/2" remains under the grate |

www.desatech.com |