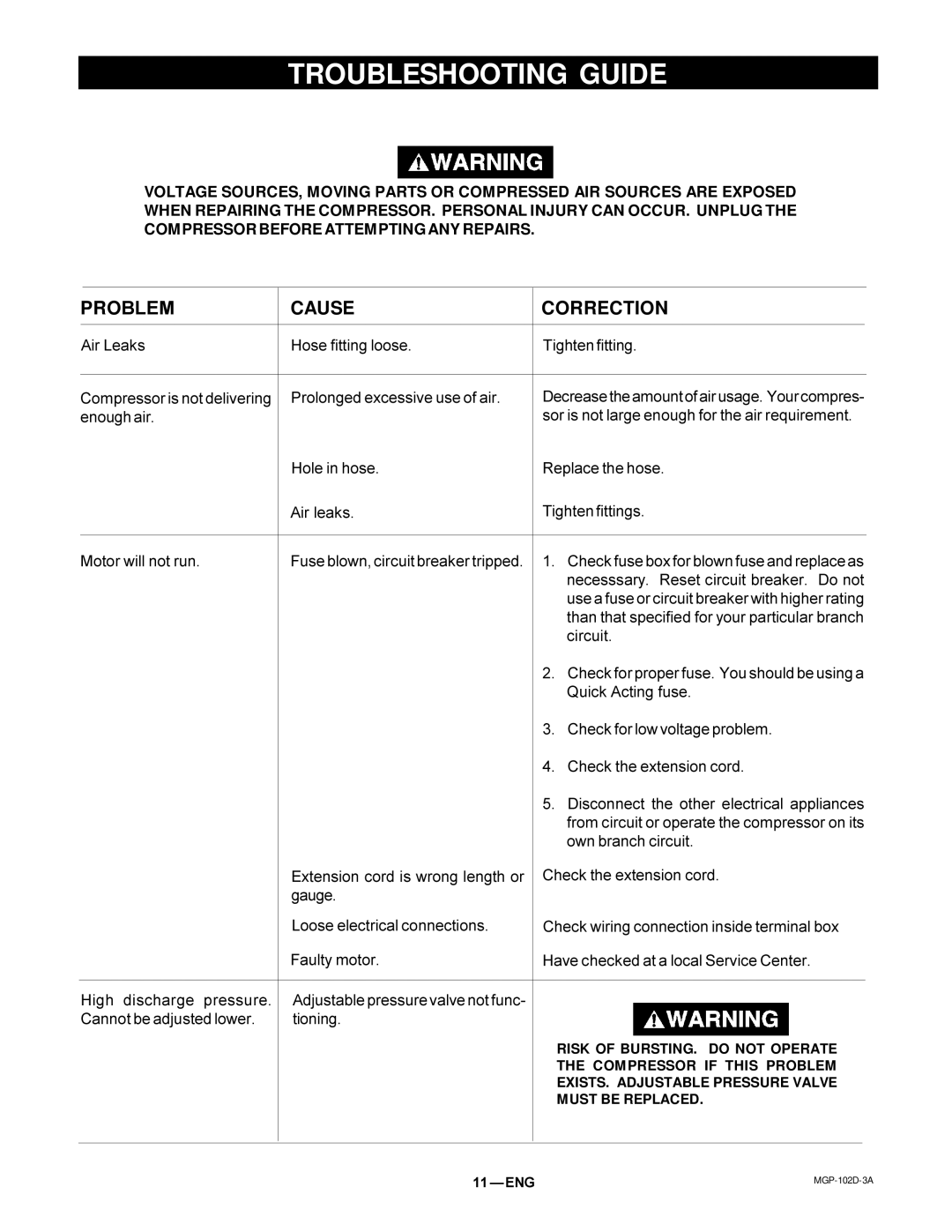

TROUBLESHOOTING GUIDE

VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED AIR SOURCES ARE EXPOSED WHEN REPAIRING THE COMPRESSOR. PERSONAL INJURY CAN OCCUR. UNPLUG THE COMPRESSOR BEFORE ATTEMPTING ANY REPAIRS.

|

|

|

|

|

|

| PROBLEM | CAUSE | CORRECTION | ||

|

|

|

|

|

|

| Air Leaks | Hose fitting loose. | Tighten fitting. | ||

|

|

|

|

|

|

| Compressor is not delivering | Prolonged excessive use of air. | Decrease the amount of air usage. Your compres- | ||

| enough air. |

| sor is not large enough for the air requirement. | ||

|

|

| Hole in hose. | Replace the hose. | |

|

|

| Air leaks. | Tighten fittings. | |

|

|

|

|

|

|

| Motor will not run. | Fuse blown, circuit breaker tripped. | 1. Check fuse box for blown fuse and replace as | ||

|

|

|

| necesssary. Reset circuit breaker. Do not | |

|

|

|

| use a fuse or circuit breaker with higher rating | |

|

|

|

| than that specified for your particular branch | |

|

|

|

| circuit. | |

|

|

|

| 2. Check for proper fuse. You should be using a | |

|

|

|

| Quick Acting fuse. | |

|

|

|

| 3. Check for low voltage problem. | |

|

|

|

| 4. Check the extension cord. | |

|

|

|

| 5. Disconnect the other electrical appliances | |

|

|

|

| from circuit or operate the compressor on its | |

|

|

|

| own branch circuit. | |

|

|

| Extension cord is wrong length or | Check the extension cord. | |

|

|

| gauge. |

|

|

|

|

| Loose electrical connections. | Check wiring connection inside terminal box | |

|

|

| Faulty motor. | Have checked at a local Service Center. | |

|

|

|

|

|

|

| High discharge pressure. | Adjustable pressure valve not func- |

|

| |

| Cannot be adjusted lower. | tioning. |

|

| |

|

|

|

| RISK OF BURSTING. DO NOT OPERATE | |

|

|

|

| THE COMPRESSOR IF THIS PROBLEM | |

|

|

|

| EXISTS. ADJUSTABLE PRESSURE VALVE | |

|

|

|

| MUST BE REPLACED. | |

|

|

|

|

|

|

|

|

|

|

|

|

11 — ENG