D28715R specifications

The DeWalt D28715R is a powerful angle grinder designed to meet the demands of both professional tradespeople and serious DIY enthusiasts. Combining performance, durability, and user-friendly features, this tool has become a go-to choice for various applications, including grinding, cutting, and polishing.One of the standout features of the D28715R is its robust 15-amp motor, which delivers an impressive no-load speed of up to 6,600 RPM. This significant power output allows for efficient material removal and quick job completion. The high-performance motor is designed for heavy-duty applications and provides the user with consistent power to tackle even the toughest tasks with ease.

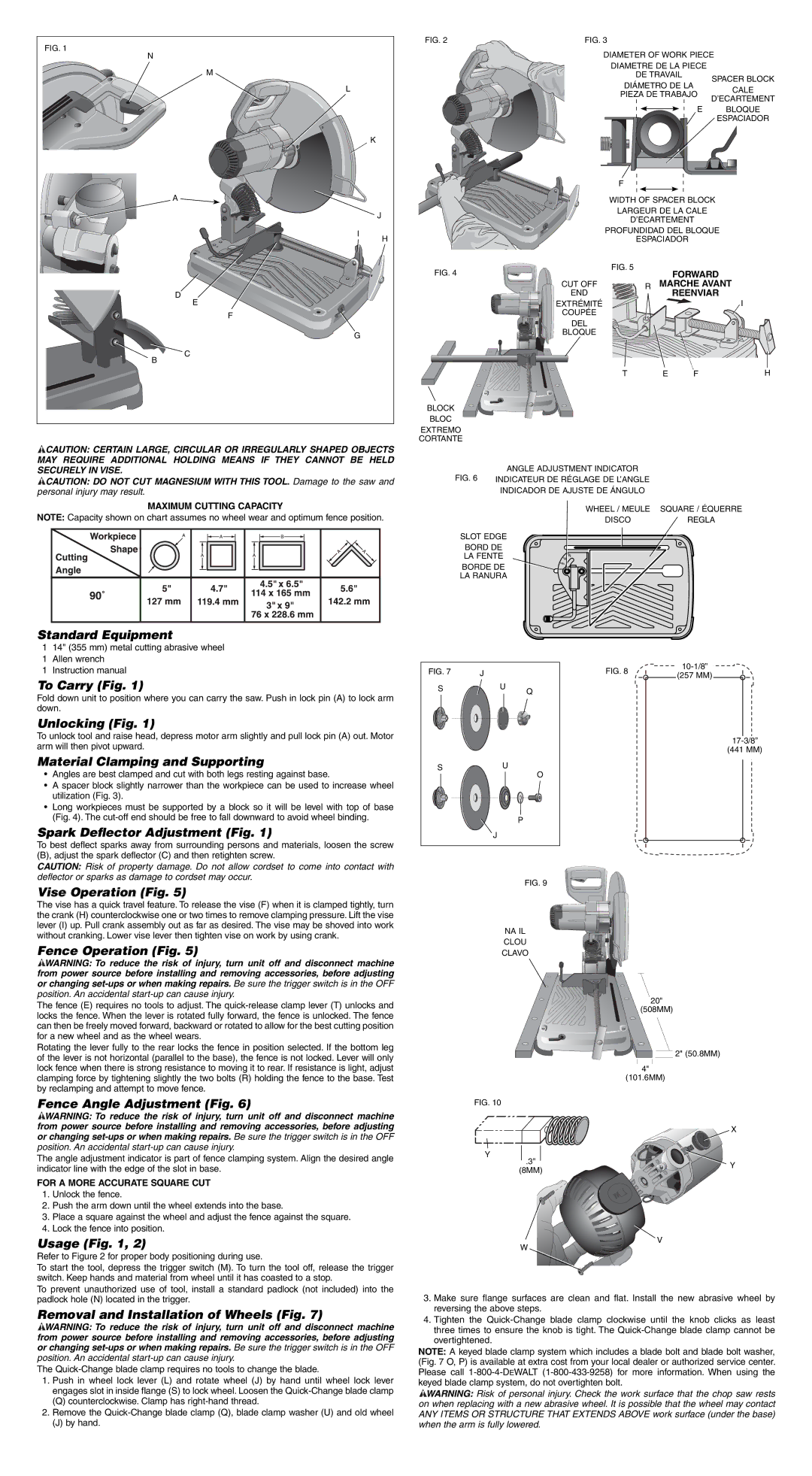

The D28715R is not just about power; it also incorporates advanced technologies to enhance user experience and safety. One such feature is the anti-vibration handle, which helps reduce fatigue during extended use. This aspect is particularly valuable for professionals who rely on this tool throughout the day. Additionally, the grinder is equipped with a spindle lock for easy disc changes, allowing users to switch between various attachments without difficulty.

Another noteworthy characteristic of the D28715R is its durable construction. Built with a cast metal gear housing, this angle grinder can withstand rigorous use in demanding environments. The design also contributes to improved gear life and better protection against wear and tear. Furthermore, the tool features a protective wheel guard that shields the user from sparks and debris while working.

The D28715R is compatible with a wide range of grinding and cutting wheels, giving users the flexibility to choose the right disc for their specific application. This versatility makes it excellent for multiple tasks, from grinding welds to cutting through rebar or other tough materials.

Weighing in at a manageable weight, the DeWalt D28715R is easy to handle, allowing for precision work in tight spaces. The tool also features a two-position side handle for added control, further enhancing its usability.

In summary, the DeWalt D28715R is a top-tier angle grinder that stands out for its powerful motor, durability, and user-friendly features. Whether you're a professional or a DIY enthusiast, this reliable tool is designed to deliver exceptional performance and efficiency in a variety of grinding and cutting applications.