DC825KAR, DC835KAR specifications

The DeWalt DC835KAR and DC825KAR are professional-grade cordless impact wrenches designed for heavy-duty applications in construction and automotive industries. These models are part of DeWalt’s growing line of high-performance power tools, renowned for their reliability and innovation.The DC835KAR model boasts a powerful 18V motor that delivers a striking torque of up to 300 ft-lbs, making it ideal for loosening and tightening stubborn fasteners with ease. It features a 1/2-inch square drive with a detent pin, allowing for secure socket retention during use. The compact design of the DC835KAR enhances maneuverability, especially in tight spaces, while the lightweight build reduces user fatigue during extended operations.

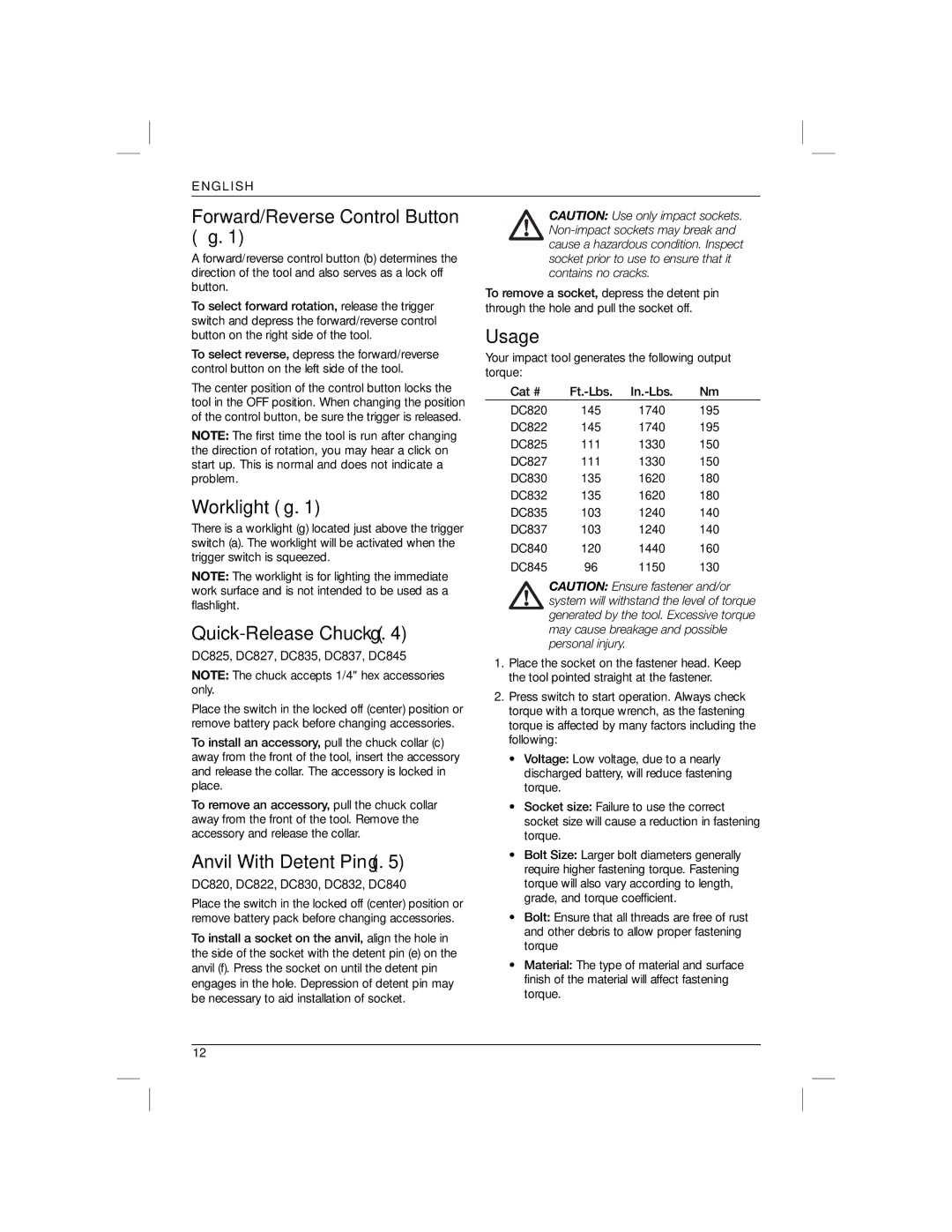

On the other hand, the DC825KAR offers an impressive torque output capable of tackling a variety of tasks. The impact wrench features a variable speed trigger, giving users finite control over the speed and power delivery while working. Its 1/4-inch hex chuck allows for quick and easy bit changes, providing versatility when switching between applications. Both models come equipped with a built-in LED light to illuminate dark work areas, enhancing visibility and precision.

DeWalt has integrated advanced battery technology into these impact wrenches, utilizing lithium-ion batteries that deliver longer run times and reduced charge times. This innovative battery management system ensures consistent power delivery and extends tool life. The tools are compatible with DeWalt’s 18V battery platform, allowing users to interchange batteries with other tools within the same range, enhancing overall efficiency on the job site.

In terms of ergonomics, both the DC835KAR and DC825KAR sport a rubberized grip, which provides comfort and ensures a secure hold even during intense applications. The lightweight design also minimizes fatigue, allowing users to tackle challenging tasks without discomfort.

Overall, the DeWalt DC835KAR and DC825KAR impact wrenches are equipped with cutting-edge features and robust technologies that cater to professionals who demand performance, durability, and versatility. Their ability to deliver exceptional torque in a compact form makes them indispensable tools for any serious tradesperson. With DeWalt’s commitment to quality and innovation, these impact wrenches stand out as powerful allies for tackling the toughest fastening challenges.