DW311K specifications

The DeWalt DW311K is a powerful reciprocating saw designed for both professional contractors and DIY enthusiasts. Known for its robust performance and versatility, this model is built to tackle a variety of cutting tasks, making it a staple in many toolkits.One of the standout features of the DW311K is its 12-amp motor. This powerful motor delivers a no-load speed of up to 2900 strokes per minute, ensuring efficient and fast cutting through various materials such as wood, metal, and plastics. The aggressive 1-1/8-inch stroke length contributes significantly to the saw's cutting speed, enabling users to complete tasks swiftly.

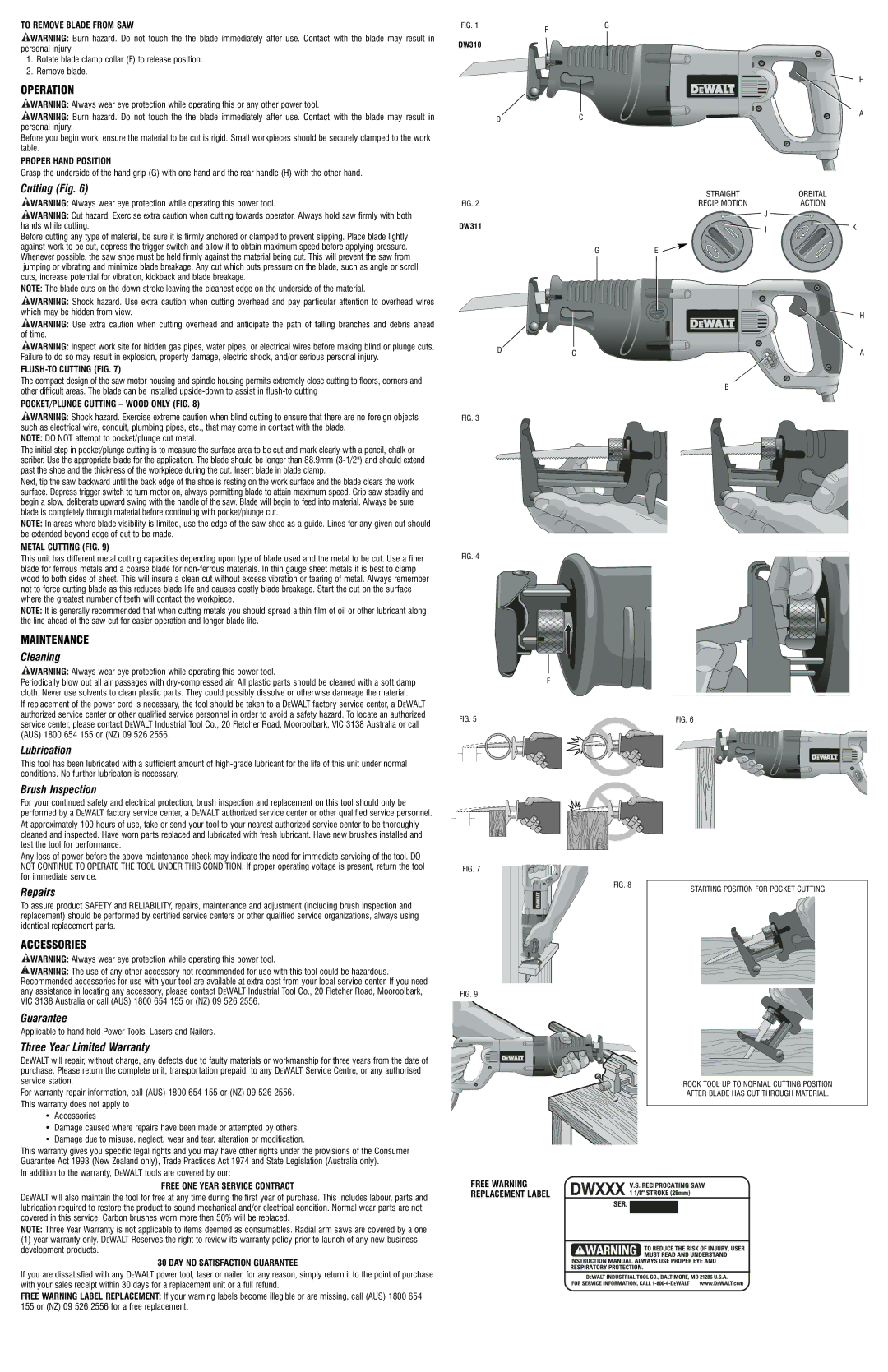

A key technology in the DW311K is its patented keyless blade clamp, which allows for quick and easy blade changes without the need for additional tools. This feature is particularly appreciated on job sites where time and efficiency are crucial. The saw is compatible with a wide range of reciprocating saw blades, adding to its versatility for different cutting applications.

The design of the DW311K incorporates a variable speed control dial. This allows users to adjust the speed setting according to the material being cut, providing greater control and precision. Whether you are making aggressive cuts through thick lumber or delicate cuts in softer materials, the ability to tailor the speed enhances the overall cutting experience.

In terms of ergonomics, the DW311K boasts a comfortable grip and lightweight construction, which reduce user fatigue during extended use. The handle is designed to provide a secure grip for better control, especially in challenging cutting positions. Additionally, the saw features an adjustable pivoting shoe that ensures maximum contact with the working surface, resulting in improved stability and better cut accuracy.

Safety is a key consideration in the design of the DW311K. The saw includes a built-in LED work light that illuminates the cutting area, enhancing visibility in dimly lit environments. Moreover, the protective casing and integrated safety features help to prevent accidental start-ups, ensuring safe operation.

In summary, the DeWalt DW311K is a high-performance reciprocating saw that combines power, speed, and user-friendly features. Its 12-amp motor, keyless blade clamp, variable speed control, and ergonomic design make it an excellent choice for professional and home use alike. With its versatility and safety features, it stands out as a reliable tool for tackling a wide range of cutting tasks.