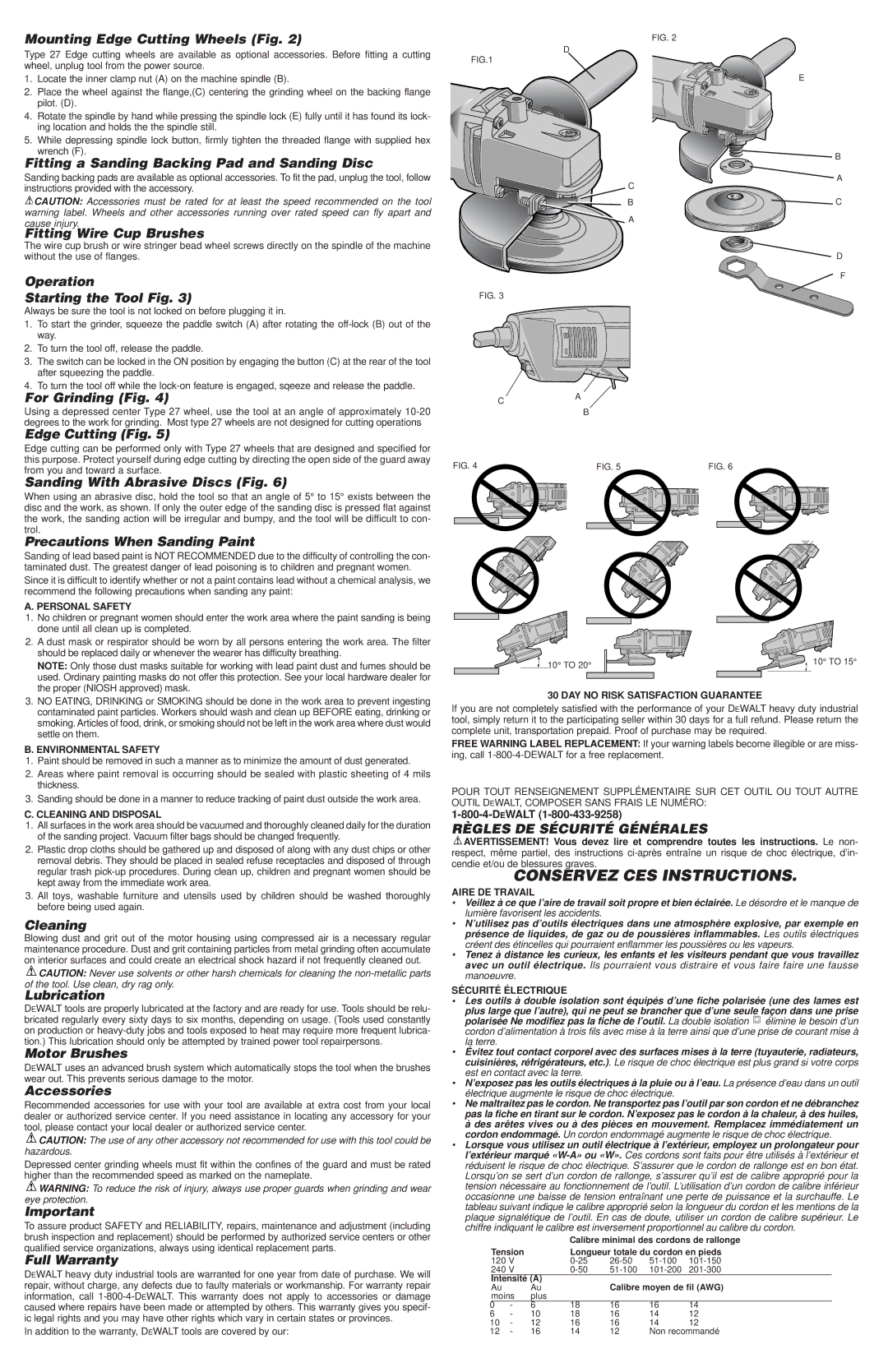

Mounting Edge Cutting Wheels (Fig. 2)

Type 27 Edge cutting wheels are available as optional accessories. Before fitting a cutting wheel, unplug tool from the power source.

1.Locate the inner clamp nut (A) on the machine spindle (B).

2.Place the wheel against the flange,(C) centering the grinding wheel on the backing flange pilot. (D).

4.Rotate the spindle by hand while pressing the spindle lock (E) fully until it has found its lock- ing location and holds the the spindle still.

5.While depressing spindle lock button, firmly tighten the threaded flange with supplied hex wrench (F).

Fitting a Sanding Backing Pad and Sanding Disc

Sanding backing pads are available as optional accessories. To fit the pad, unplug the tool, follow instructions provided with the accessory.

![]() CAUTION: Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over rated speed can fly apart and cause injury.

CAUTION: Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other accessories running over rated speed can fly apart and cause injury.

Fitting Wire Cup Brushes

The wire cup brush or wire stringer bead wheel screws directly on the spindle of the machine without the use of flanges.

Operation

Starting the Tool Fig. 3)

Always be sure the tool is not locked on before plugging it in.

1.To start the grinder, squeeze the paddle switch (A) after rotating the

2.To turn the tool off, release the paddle.

3.The switch can be locked in the ON position by engaging the button (C) at the rear of the tool after squeezing the paddle.

4.To turn the tool off while the

For Grinding (Fig. 4)

Using a depressed center Type 27 wheel, use the tool at an angle of approximately

Edge Cutting (Fig. 5)

Edge cutting can be performed only with Type 27 wheels that are designed and specified for this purpose. Protect yourself during edge cutting by directing the open side of the guard away from you and toward a surface.

Sanding With Abrasive Discs (Fig. 6)

When using an abrasive disc, hold the tool so that an angle of 5° to 15° exists between the disc and the work, as shown. If only the outer edge of the sanding disc is pressed flat against the work, the sanding action will be irregular and bumpy, and the tool will be difficult to con- trol.

Precautions When Sanding Paint

Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the con- taminated dust. The greatest danger of lead poisoning is to children and pregnant women.

Since it is difficult to identify whether or not a paint contains lead without a chemical analysis, we recommend the following precautions when sanding any paint:

A. PERSONAL SAFETY

1.No children or pregnant women should enter the work area where the paint sanding is being done until all clean up is completed.

2.A dust mask or respirator should be worn by all persons entering the work area. The filter should be replaced daily or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should be used. Ordinary painting masks do not offer this protection. See your local hardware dealer for the proper (NIOSH approved) mask.

3.NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting contaminated paint particles. Workers should wash and clean up BEFORE eating, drinking or smoking. Articles of food, drink, or smoking should not be left in the work area where dust would settle on them.

B. ENVIRONMENTAL SAFETY

1.Paint should be removed in such a manner as to minimize the amount of dust generated.

2.Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils thickness.

3.Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

C. CLEANING AND DISPOSAL

1.All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration of the sanding project. Vacuum filter bags should be changed frequently.

2.Plastic drop cloths should be gathered up and disposed of along with any dust chips or other removal debris. They should be placed in sealed refuse receptacles and disposed of through regular trash

3.All toys, washable furniture and utensils used by children should be washed thoroughly before being used again.

Cleaning

Blowing dust and grit out of the motor housing using compressed air is a necessary regular maintenance procedure. Dust and grit containing particles from metal grinding often accumulate on interior surfaces and could create an electrical shock hazard if not frequently cleaned out.

![]() CAUTION: Never use solvents or other harsh chemicals for cleaning the

CAUTION: Never use solvents or other harsh chemicals for cleaning the

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for use. Tools should be relu- bricated regularly every sixty days to six months, depending on usage. (Tools used constantly on production or

Motor Brushes

DEWALT uses an advanced brush system which automatically stops the tool when the brushes wear out. This prevents serious damage to the motor.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory for your tool, please contact your local dealer or authorized service center.

![]() CAUTION: The use of any other accessory not recommended for use with this tool could be hazardous.

CAUTION: The use of any other accessory not recommended for use with this tool could be hazardous.

Depressed center grinding wheels must fit within the confines of the guard and must be rated higher than the recommended speed as marked on the nameplate.

![]() WARNING: To reduce the risk of injury, always use proper guards when grinding and wear eye protection.

WARNING: To reduce the risk of injury, always use proper guards when grinding and wear eye protection.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from date of purchase. We will repair, without charge, any defects due to faulty materials or workmanship. For warranty repair information, call

In addition to the warranty, DEWALT tools are covered by our:

FIG. 2

D

FIG.1

E

![]() B

B

![]() A

A

C

B![]()

![]() C

C

A

D

F

FIG. 3

CA

B

FIG. 4 | FIG. 5 |

|

|

|

|

|

| FIG. 6 |

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10° TO 20° | 10° TO 15° |

|

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your DEWALT heavy duty industrial tool, simply return it to the participating seller within 30 days for a full refund. Please return the complete unit, transportation prepaid. Proof of purchase may be required.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are miss- ing, call

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSER SANS FRAIS LE NUMÉRO:

RÈGLES DE SÉCURITÉ GÉNÉRALES

![]() AVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le non- respect, même partiel, des instructions

AVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le non- respect, même partiel, des instructions

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

•Veillez à ce que l’aire de travail soit propre et bien éclairée. Le désordre et le manque de lumière favorisent les accidents.

•N’utilisez pas d’outils électriques dans une atmosphère explosive, par exemple en présence de liquides, de gaz ou de poussières inflammables. Les outils électriques créent des étincelles qui pourraient enflammer les poussières ou les vapeurs.

•Tenez à distance les curieux, les enfants et les visiteurs pendant que vous travaillez avec un outil électrique. Ils pourraient vous distraire et vous faire faire une fausse manoeuvre.

SÉCURITÉ ÉLECTRIQUE

•Les outils à double isolation sont équipés d’une fiche polarisée (une des lames est

plus large que l’autre), qui ne peut se brancher que d’une seule façon dans une prise

polarisée Ne modifiez pas la fiche de l’outil. La double isolation ![]()

![]()

![]()

![]() élimine le besoin d’un cordon d’alimentation à trois fils avec mise à la terre ainsi que d’une prise de courant mise à la terre.

élimine le besoin d’un cordon d’alimentation à trois fils avec mise à la terre ainsi que d’une prise de courant mise à la terre.

•Évitez tout contact corporel avec des surfaces mises à la terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.) . Le risque de choc électrique est plus grand si votre corps est en contact avec la terre.

•N’exposez pas les outils électriques à la pluie ou à l’eau. La présence d’eau dans un outil électrique augmente le risque de choc électrique.

•Ne maltraitez pas le cordon. Ne transportez pas l’outil par son cordon et ne débranchez pas la fiche en tirant sur le cordon. N’exposez pas le cordon à la chaleur, à des huiles, à des arêtes vives ou à des pièces en mouvement. Remplacez immédiatement un cordon endommagé. Un cordon endommagé augmente le risque de choc électrique.

•Lorsque vous utilisez un outil électrique à l’extérieur, employez un prolongateur pour l’extérieur marqué

Calibre minimal des cordons de rallonge

| Tension |

| Longueur totale du cordon en pieds | ||||

| 120 V |

| |||||

| 240 V |

| |||||

| Intensité (A) |

| Calibre moyen de fil (AWG) | ||||

| Au |

| Au |

| |||

| moins | plus |

|

|

|

| |

0 | - | 6 | 18 | 16 | 16 | 14 | |

6 | - | 10 | 18 | 16 | 14 | 12 | |

10 | - | 12 | 16 | 16 | 14 | 12 | |

12 | - | 16 | 14 | 12 | Non recommandé | ||