DW758 specifications

DeWalt is renowned for producing high-quality tools, and two of their standout products in the bench grinder category are the DW758 and DW756. These models epitomize durability and performance, making them ideal for both professional and home use.The DeWalt DW758 is a powerful 8-inch bench grinder that operates at a robust 3,600 RPM, providing exceptional grinding capabilities. This model features a heavy-duty motor designed for a range of applications, including metal shaping, sharpening, and polishing. Its high-performance motor ensures consistent power delivery and enables users to work on tough materials with ease.

One of the primary characteristics of the DW758 is its cast iron base, which enhances stability during operation. This design not only minimizes vibrations but also prolongs the lifespan of the grinder. The grinder comes equipped with two 8-inch grinding wheels, permitting users to perform a variety of tasks without needing multiple tools. The included 36-grit and 60-grit wheels support different grinding applications, allowing for both coarse and fine finishes.

On the other hand, the DeWalt DW756 is an equally compelling option, featuring a slightly smaller design while still retaining impressive power. The DW756 operates at a speed of 3,450 RPM, making it suitable for handling general grindings tasks. Like its counterpart, this model also features a rugged cast iron base for stability and reduced vibration, ensuring a smoother grinding experience.

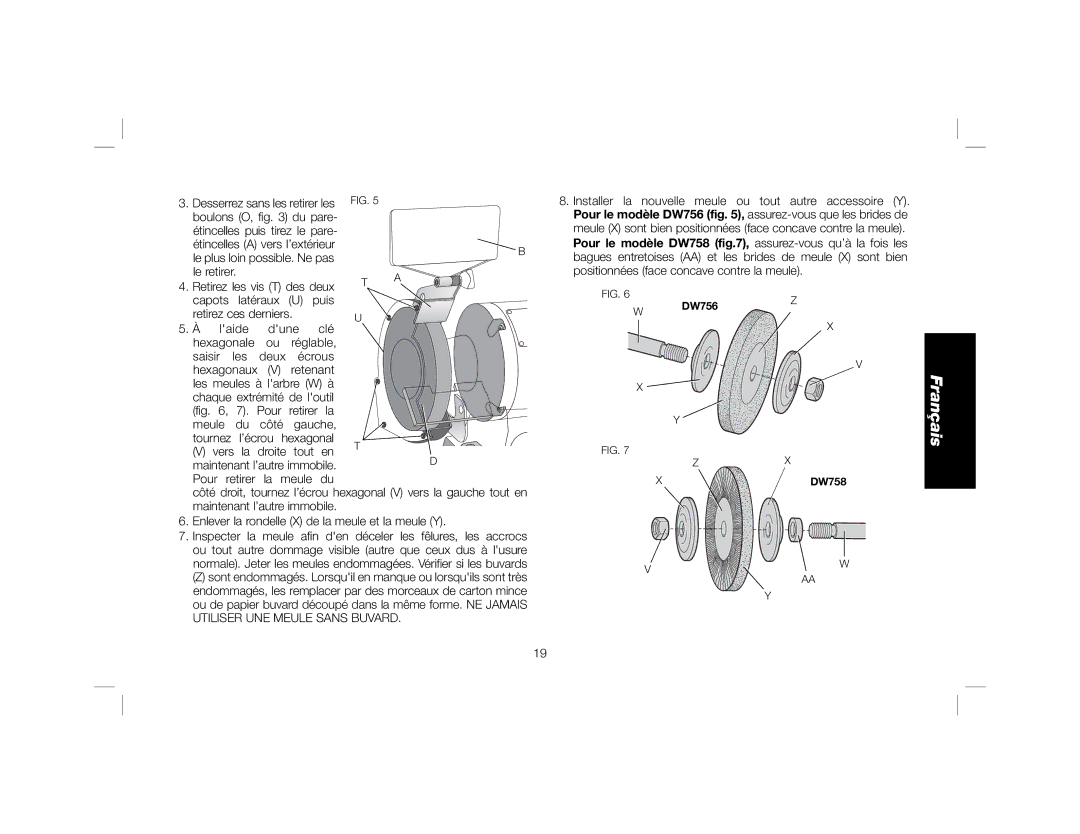

Both grinders utilize high-quality components such as the precision-machined shaft and balancing wheels, which contribute to their accuracy and efficiency. Additionally, the adjustable tool rests on both models allow users to customize their setups for optimal comfort and control. Safety features, including eye shields and toggle switches, are also standard, providing an added layer of protection for users.

In terms of versatility, both models are designed to accommodate a variety of accessories, making them adaptable to different tasks. With their robust build, powerful motors, and user-friendly features, the DeWalt DW758 and DW756 are excellent choices for anyone looking to enhance their workshop with reliable bench grinders. Whether for professional use or hobbyist projects, these grinders excel in performance, making them invaluable tools for achieving precise results.