Grinding

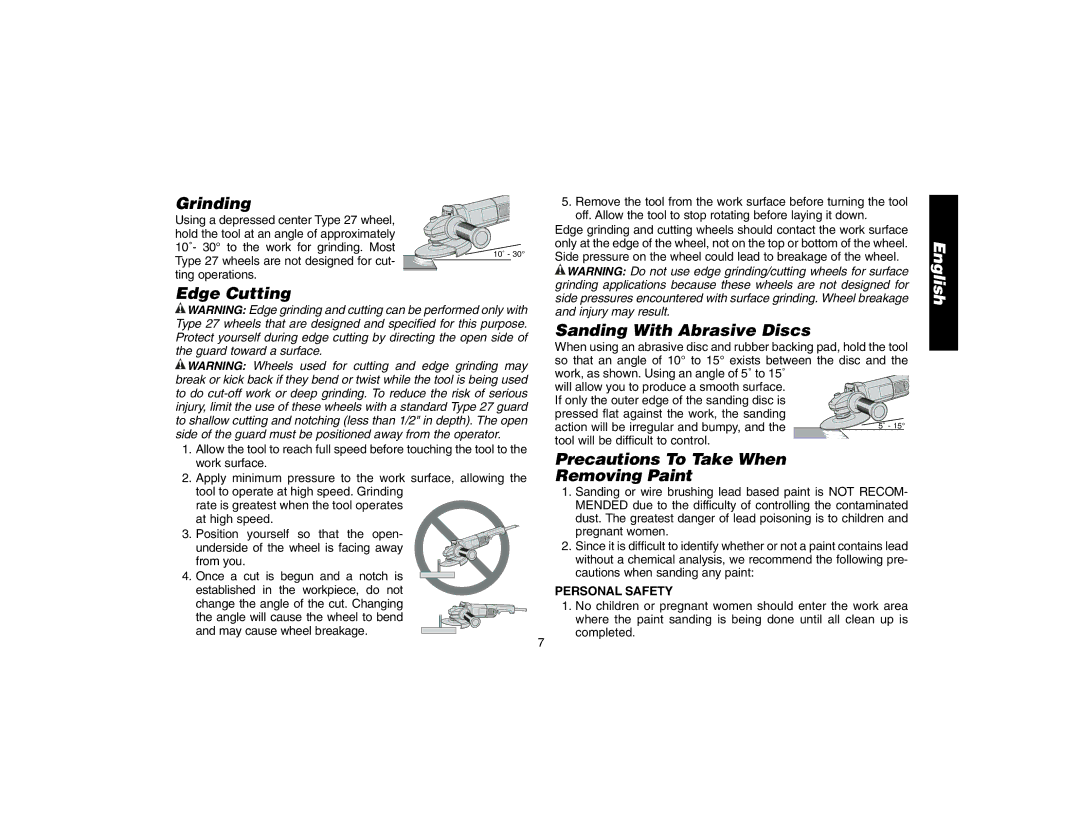

Using a depressed center Type 27 wheel, hold the tool at an angle of approximately 10˚- 30° to the work for grinding. Most Type 27 wheels are not designed for cut- ting operations.

Edge Cutting

10˚ - 30°

5.Remove the tool from the work surface before turning the tool off. Allow the tool to stop rotating before laying it down.

Edge grinding and cutting wheels should contact the work surface |

|

only at the edge of the wheel, not on the top or bottom of the wheel. | English |

Side pressure on the wheel could lead to breakage of the wheel. | |

WARNING: Do not use edge grinding/cutting wheels for surface | |

grinding applications because these wheels are not designed for | |

side pressures encountered with surface grinding. Wheel breakage |

![]() WARNING: Edge grinding and cutting can be performed only with Type 27 wheels that are designed and specified for this purpose. Protect yourself during edge cutting by directing the open side of the guard toward a surface.

WARNING: Edge grinding and cutting can be performed only with Type 27 wheels that are designed and specified for this purpose. Protect yourself during edge cutting by directing the open side of the guard toward a surface.

![]() WARNING: Wheels used for cutting and edge grinding may break or kick back if they bend or twist while the tool is being used to do

WARNING: Wheels used for cutting and edge grinding may break or kick back if they bend or twist while the tool is being used to do

1.Allow the tool to reach full speed before touching the tool to the work surface.

2.Apply minimum pressure to the work surface, allowing the tool to operate at high speed. Grinding

rate is greatest when the tool operates at high speed.

3. Position yourself so that the open- underside of the wheel is facing away from you.

4. Once a cut is begun and a notch is established in the workpiece, do not change the angle of the cut. Changing the angle will cause the wheel to bend and may cause wheel breakage.

and injury may result. |

|

Sanding With Abrasive Discs |

|

When using an abrasive disc and rubber backing pad, hold the tool | |

so that an angle of 10° to 15° exists between the disc and the | |

work, as shown. Using an angle of 5˚ to 15˚ |

|

will allow you to produce a smooth surface. |

|

If only the outer edge of the sanding disc is |

|

pressed flat against the work, the sanding |

|

action will be irregular and bumpy, and the | 5˚ - 15° |

tool will be difficult to control. |

|

Precautions To Take When

Removing Paint

1.Sanding or wire brushing lead based paint is NOT RECOM- MENDED due to the difficulty of controlling the contaminated dust. The greatest danger of lead poisoning is to children and pregnant women.

2.Since it is difficult to identify whether or not a paint contains lead without a chemical analysis, we recommend the following pre- cautions when sanding any paint:

PERSONAL SAFETY

1.No children or pregnant women should enter the work area where the paint sanding is being done until all clean up is completed.

7