INSTALLATION

Air Supply

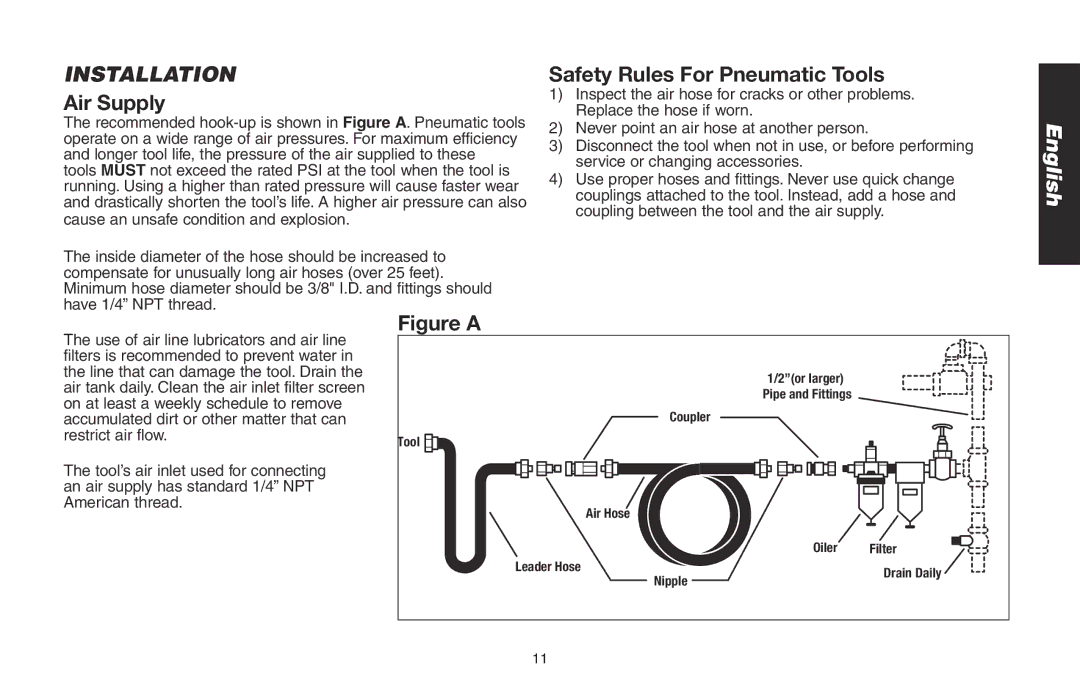

The recommended

The inside diameter of the hose should be increased to compensate for unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8" I.D. and fittings should have 1/4” NPT thread.

Safety Rules For Pneumatic Tools

1)Inspect the air hose for cracks or other problems. Replace the hose if worn.

2)Never point an air hose at another person.

3)Disconnect the tool when not in use, or before performing service or changing accessories.

4)Use proper hoses and fittings. Never use quick change couplings attached to the tool. Instead, add a hose and coupling between the tool and the air supply.

English

The use of air line lubricators and air line filters is recommended to prevent water in the line that can damage the tool. Drain the air tank daily. Clean the air inlet filter screen on at least a weekly schedule to remove accumulated dirt or other matter that can restrict air flow.

The tool’s air inlet used for connecting an air supply has standard 1/4” NPT American thread.

1/2”(or larger) |

| |

Pipe and Fittings |

| |

Coupler |

| |

Tool |

| |

Air Hose |

| |

Oiler | Filter | |

Leader Hose | Drain Daily | |

Nipple | ||

| ||

11 |

|