18124-106 specifications

The Dixon 18124-106 is a versatile and robust product designed for a variety of industrial and commercial applications. Renowned for its quality and reliability, this model exemplifies Dixon's commitment to innovation and performance.One of the main features of the Dixon 18124-106 is its durable construction. It is manufactured from high-quality materials that ensure longevity and resistance to wear and tear. This makes it an ideal choice for environments where exposure to chemicals, extreme temperatures, or physical stress is likely. The design incorporates robust seals and fittings that enhance its overall functionality and performance.

Technologically, the Dixon 18124-106 is equipped with advanced features that improve its efficiency and ease of use. The model includes a user-friendly interface that allows for simple operation, making it accessible to both seasoned professionals and newcomers to the industry. The integration of precision engineering techniques ensures that the product operates smoothly and reliably, minimizing downtime in critical processes.

Another characteristic of the Dixon 18124-106 is its versatility. It is compatible with a wide range of attachments and accessories, enabling users to customize it according to their specific needs. This adaptability makes it suitable for various applications, from fluid transfer to handling gases and other materials. The ability to interchange components allows for increased efficiency and productivity on the job.

Furthermore, the Dixon 18124-106 adheres to industry safety standards, ensuring that it can be used in compliance with regulatory requirements. The model features safety mechanisms that prevent accidental misuse, protecting both the operator and the equipment. This attention to safety is a crucial aspect of Dixon's product design philosophy.

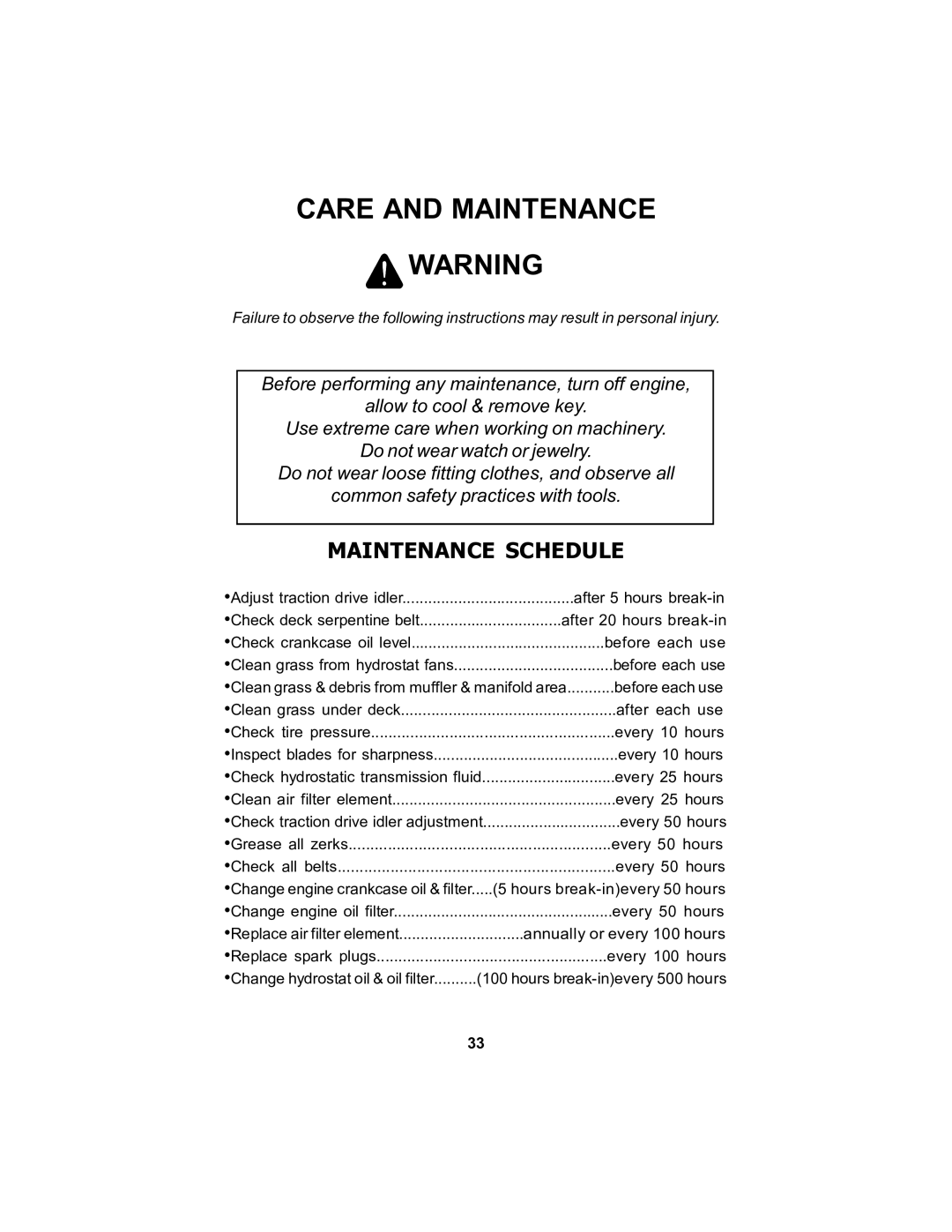

In terms of maintenance, the Dixon 18124-106 is designed for ease of upkeep. Its modular construction allows for straightforward disassembly and cleaning, which is essential for maintaining operational standards in industries such as food processing and pharmaceuticals. Regular maintenance is simplified, enabling users to keep their equipment in prime condition for optimal performance.

Overall, the Dixon 18124-106 stands out in its category, driven by quality engineering, user-centric design, and a commitment to safety and efficiency. Whether in construction, manufacturing, or other industrial fields, this model delivers the performance and reliability professionals depend on.