Ni-MH Rechargeable Batteries

Pe

Pe

rformance

rformance Characteristics

Characteristics (cont.)

(cont.)

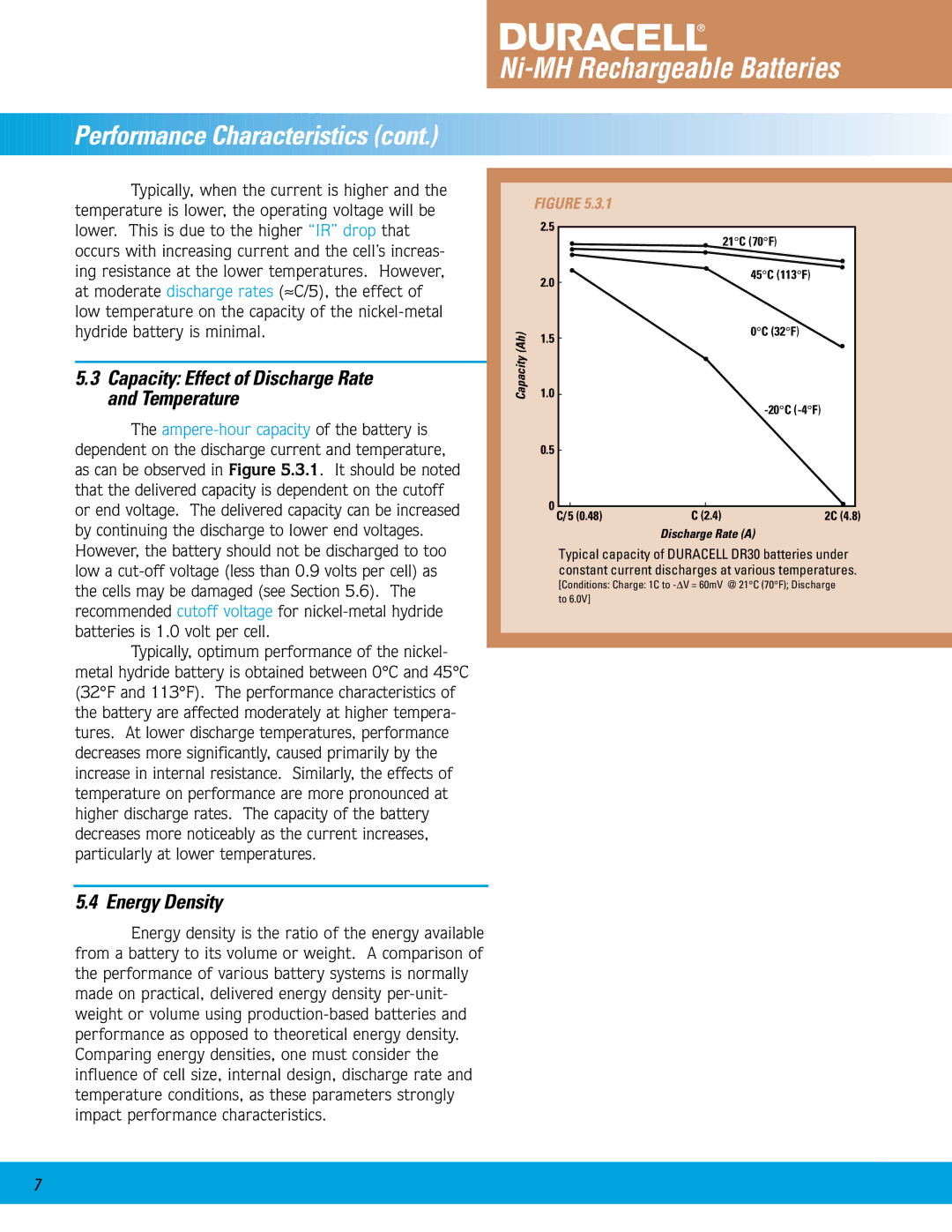

Typically, when the current is higher and the temperature is lower, the operating voltage will be lower. This is due to the higher “IR” drop that occurs with increasing current and the cell’s increas- ing resistance at the lower temperatures. However, at moderate discharge rates (≈C/5), the effect of low temperature on the capacity of the

5.3Capacity: Effect of Discharge Rate and Temperature

The

Typically, optimum performance of the nickel- metal hydride battery is obtained between 0°C and 45°C (32°F and 113°F). The performance characteristics of the battery are affected moderately at higher tempera- tures. At lower discharge temperatures, performance decreases more significantly, caused primarily by the increase in internal resistance. Similarly, the effects of temperature on performance are more pronounced at higher discharge rates. The capacity of the battery decreases more noticeably as the current increases, particularly at lower temperatures.

FIGURE 5.3.1

| 2.5 | 21°C (70°F) |

|

| |

| 2.0 | 45°C (113°F) |

|

| |

Capacity (Ah) | 1.5 | 0°C (32°F) |

| ||

1.0 | ||

|

| |

| 0.5 |

|

| 0 |

|

C/5 (0.48) | C (2.4) | 2C (4.8) |

| Discharge Rate (A) |

|

Typical capacity of DURACELL DR30 batteries under constant current discharges at various temperatures.

[Conditions: Charge: 1C to

5.4 Energy Density

Energy density is the ratio of the energy available from a battery to its volume or weight. A comparison of the performance of various battery systems is normally made on practical, delivered energy density

7