If you need to drill a hole in the transom to pass the connector through, the required hole size is 5/8". (If you intend to route an additional speed or temp sensor cable through the same hole, you will need a 1" (25.4 mm) drill bit instead.)

Caution:

If you drill a hole in the transom for the cable, make sure it is located above the waterline. After installation, be sure to seal the hole with the same marine grade above- or

7.Make a test run to determine the results. If the bottom is lost at high speed, or if noise appears on the display, try sliding the trans- ducer bracket down. This puts the transducer deeper into the water, hopefully below the turbulence causing the noise. Don't allow the transducer bracket to go below the bottom of the hull!

Trolling Motor Bracket Installation

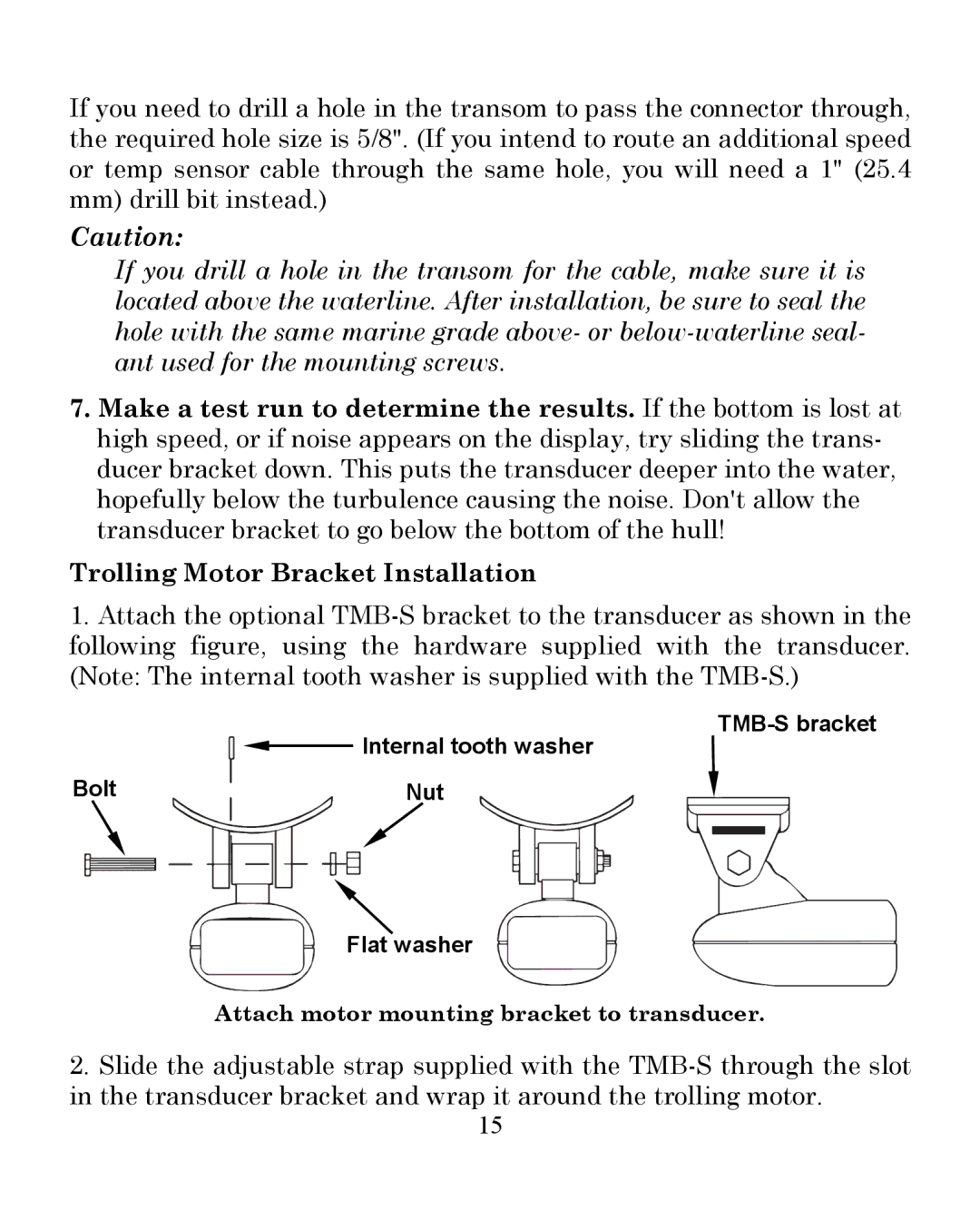

1.Attach the optional

![]()

![]() Internal tooth washer

Internal tooth washer

BoltNut

Flat washer

Attach motor mounting bracket to transducer.

2.Slide the adjustable strap supplied with the

15