A X 3 4 4 S p e c i f i c a t i o n s

group · I

AX SERIES TECHNOLOGY

CONVENTIONAL LOUDSPEAKERS

Good arrayability depends on the beamwidth patterns as well as the

To eliminate arrival time differences, provide smooth

COAXIAL DRIVERS

A solution for the above problems is the

(CSA) CONCENTRIC SUMMATION ARRAY TECHNOLOGY

To solve these problems, EAW Engineers developed a new, sealed, coaxial driver. Its MF cone and HF compression drivers share a single magnet structure, bringing the MF and HF sources as close together as physically possible. This produces an Acoustic Singularity, essentially a point source, over the MF/HF operating range of 275 Hz to 20 kHz.

The real challenge was coupling this MF/HF device to a single horn without the acoustical difficulties of typical coaxial drivers. This required creating both an

Fig 1 - Conventional High Output Loudspeaker

Fig 2 - Typical Coax HF Expansion

Fig 3 - AX Coax HF Expansion

Fig 4 - AX Coaxial Driver

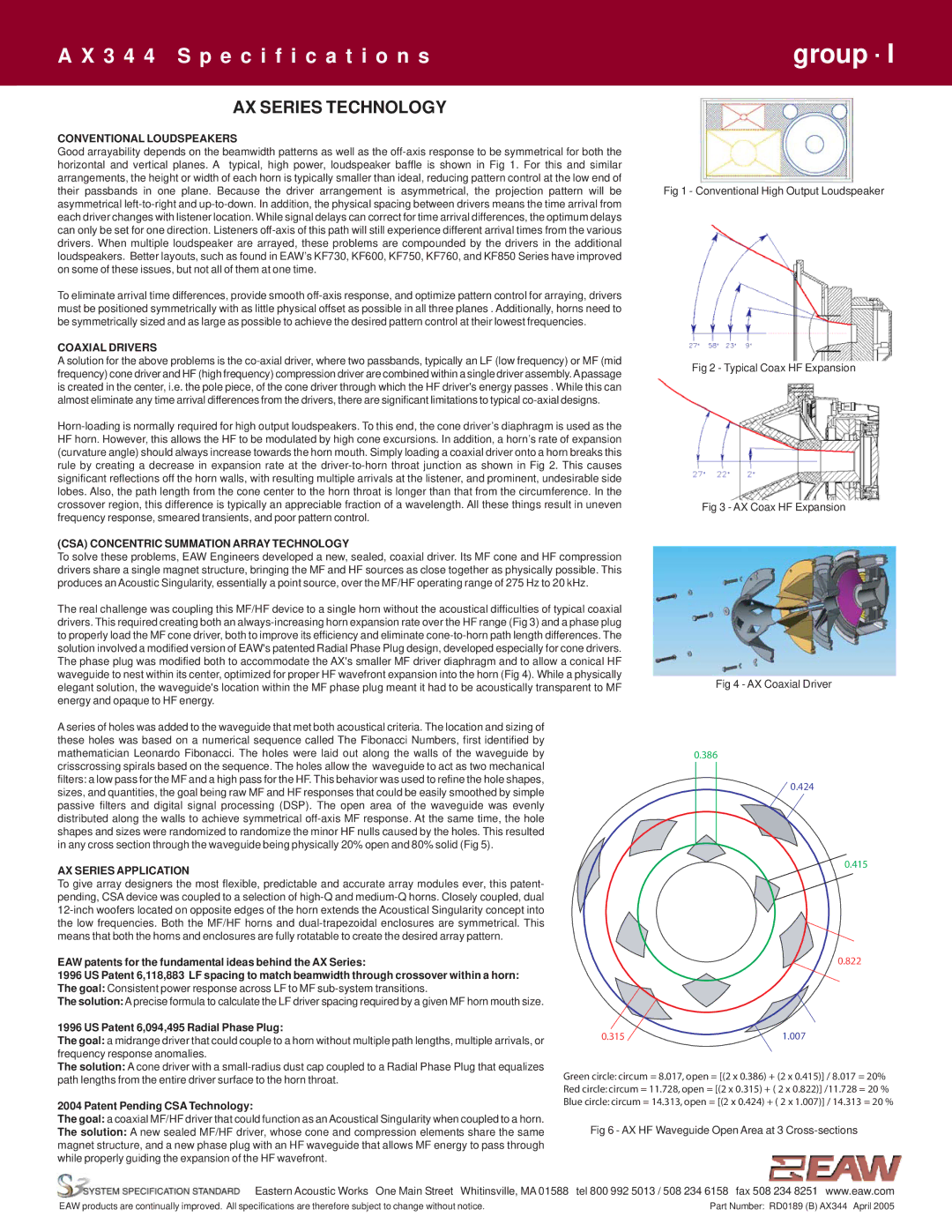

Aseries of holes was added to the waveguide that met both acoustical criteria. The location and sizing of these holes was based on a numerical sequence called The Fibonacci Numbers, first identified by mathematician Leonardo Fibonacci. The holes were laid out along the walls of the waveguide by crisscrossing spirals based on the sequence. The holes allow the waveguide to act as two mechanical filters: a low pass for the MF and a high pass for the HF. This behavior was used to refine the hole shapes, sizes, and quantities, the goal being raw MF and HF responses that could be easily smoothed by simple passive filters and digital signal processing (DSP). The open area of the waveguide was evenly distributed along the walls to achieve symmetrical

AX SERIES APPLICATION

To give array designers the most flexible, predictable and accurate array modules ever, this patent- pending, CSA device was coupled to a selection of

EAW patents for the fundamental ideas behind the AX Series:

1996 US Patent 6,118,883 LF spacing to match beamwidth through crossover within a horn: The goal: Consistent power response across LF to MF

The solution: Aprecise formula to calculate the LF driver spacing required by a given MF horn mouth size.

1996 US Patent 6,094,495 Radial Phase Plug:

The goal: a midrange driver that could couple to a horn without multiple path lengths, multiple arrivals, or frequency response anomalies.

The solution: A cone driver with a

2004 Patent Pending CSA Technology:

The goal: a coaxial MF/HF driver that could function as an Acoustical Singularity when coupled to a horn.

The solution: A new sealed MF/HF driver, whose cone and compression elements share the same magnet structure, and a new phase plug with an HF waveguide that allows MF energy to pass through while properly guiding the expansion of the HF wavefront.

0.386

0.424

0.415

0.822

0.315 | 1.007 |

Green circle: circum = 8.017, open = [(2 x 0.386) + (2 x 0.415)] / 8.017 = 20%

Red circle: circum = 11.728, open = [(2 x 0.315) + ( 2 x 0.822)] /11.728 = 20 %

Blue circle: circum = 14.313, open = [(2 x 0.424) + ( 2 x 1.007)] / 14.313 = 20 %

Fig 6 - AX HF Waveguide Open Area at 3

Eastern Acoustic Works One Main Street Whitinsville, MA 01588 tel 800 992 5013 / 508 234 6158 fax 508 234 8251 www.eaw.com

EAW products are continually improved. All specifications are therefore subject to change without notice. | Part Number: RD0189 (B) AX344 April 2005 |