AH-MA specifications

Eclipse Combustion has long been a leader in the field of combustion technology, and the AH-MA series exemplifies their commitment to innovation and efficiency. The AH-MA burner is specifically designed for industrial applications where reliability, performance, and environmental compliance are critical.One of the main features of the Eclipse Combustion AH-MA burner is its versatility. It can be configured to operate with various fuels, including natural gas, propane, and other liquid fuels. This adaptability makes it suitable for numerous industries, such as manufacturing, food processing, and chemical production.

The AH-MA utilizes advanced engineering designs that promote optimal combustion efficiency. This is achieved through its unique air-to-fuel ratio control system, which ensures that the burner operates at the ideal mixture for complete combustion. This not only maximizes fuel efficiency but also minimizes emissions, making the AH-MA an environmentally friendly option for industrial users.

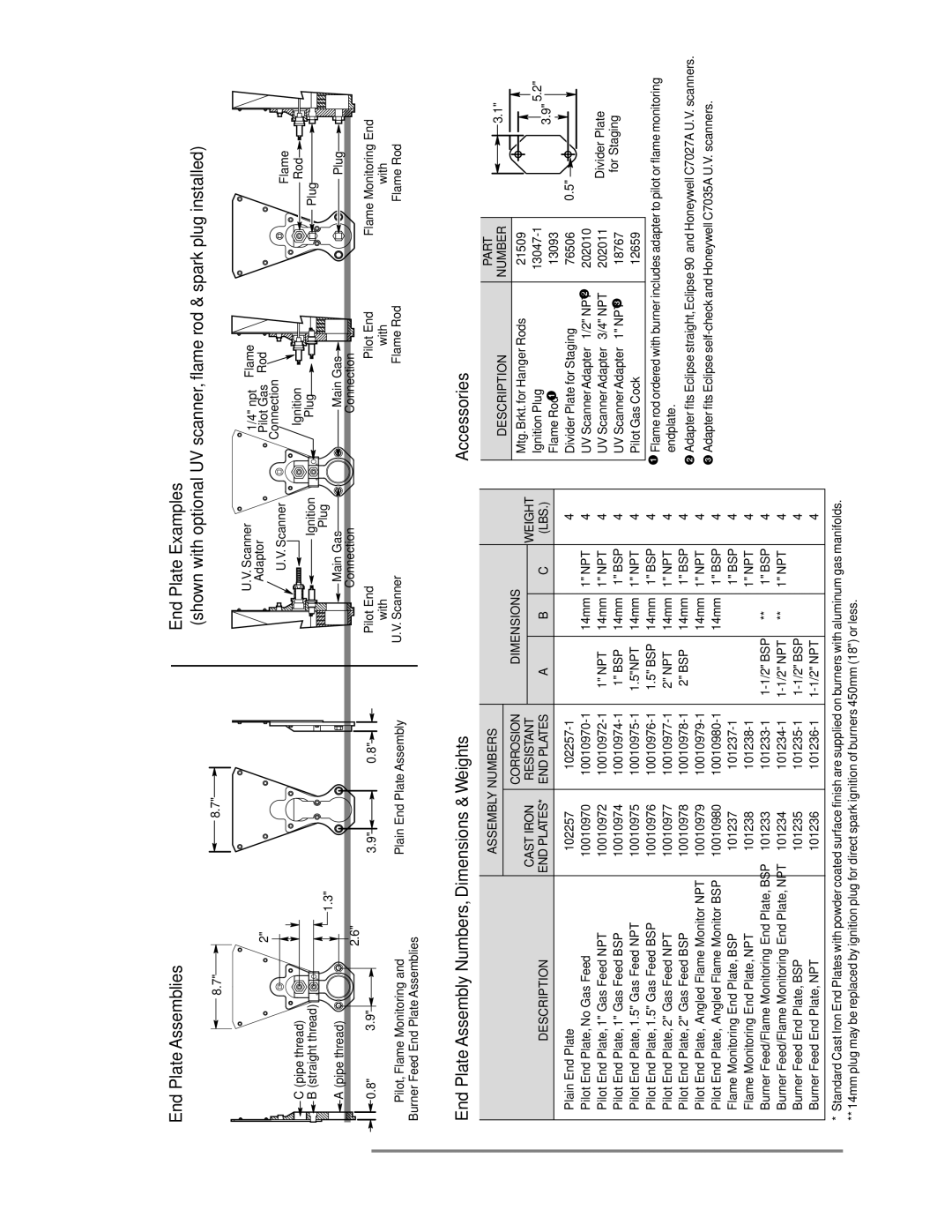

Another key characteristic of the AH-MA burner is its compact design. The burner is engineered to fit into tight spaces, making installation straightforward in existing facilities. Despite its small footprint, the AH-MA does not compromise on performance, delivering high thermal efficiency and robust output across a range of operating conditions.

The burner is equipped with advanced ignition systems that enhance safety and reliability. The automatic ignition ensures that the burner starts seamlessly while minimizing the risk of unburned fuel. Additionally, the AH-MA offers integrated safety features such as flame supervision and pressure monitoring to prevent operational hazards.

Eclipse Combustion also prioritizes ease of maintenance in the design of the AH-MA. The burner is constructed for quick access to vital components, reducing downtime during servicing. Regular maintenance checks are simplified, allowing operators to keep the burner running at peak performance with minimal disruption.

Furthermore, the AH-MA incorporates digital control systems that enable real-time monitoring and adjustments. This technology provides operators with valuable data on combustion performance, allowing for timely interventions to optimize efficiency and reduce fuel costs.

In summary, the Eclipse Combustion AH-MA burner stands out in the industrial sector for its versatility, efficiency, compact design, and safety features. With its advanced technologies, the AH-MA is not only a reliable choice for industrial combustion needs but also a step towards a more sustainable and responsible energy future.