The chain brake should snap into both positions.If strong resistance is felt or lever does not move into either position, DO NOT USE YOUR SAW. Take it imme- diately to an authorized servicing dealer.

3CHAIN CATCHER

This unit is fitted with a chain catcher below the drive spocket. This is intended to stop the rearward movement of the chain in case of breakage or if it should come out of the bar. It should never be removed.

L. Chain sharpening

1Chain cutter teeth can be sharpened with a round file, as follows:

CHAIN |

| FILE |

MP 370 | GLX | 5/32” |

PM 320 | GX | 3/16” |

The exact chain type is marked on the bottom half of the drive link which runs inside the bar groove.

Filing can be made easier by also using a file holder. The chain can remain fitted on the bar during sharpening. Before commencing, the chain should be tensioned cor- rectly and the chain brake should be activated to prevent the chain from moving.

2To obtain a correct sharpening the file must be carefully held to maintain 3 basic angles:

– “A” Top angle | 30° - 35° |

– “B” External, side angle | 85° - 90° |

– “C” Internal, side angle | 60° |

File in one direction only, from the “inside” of the cutter tooth towards the “outside”.

Do not allow the file to touch the chain as you bring it back to

3The file should be held horizontally to the cutter tooth being sharpened.

4Best results to obtain a precise sideways angle can be obtained by holding the file so that it rises 0,5 mm above the top face of the cutter tooth.

5DEPTH GAUGE

Correct depth gauge height is vital to ensure maximum chain life and cutting efficiency.

The height of the depth gauge should be lowered as the cutter tooth is filed back; this height should be checked every 4 or 5 sharpenings.

The best way to do this is to use a flat file and a depth gauge tool.

The correct setting is 0.65 mm below the top edge of the cutter tooth.

The cutter tooth depth gauge should then be rounded (D).

Specification

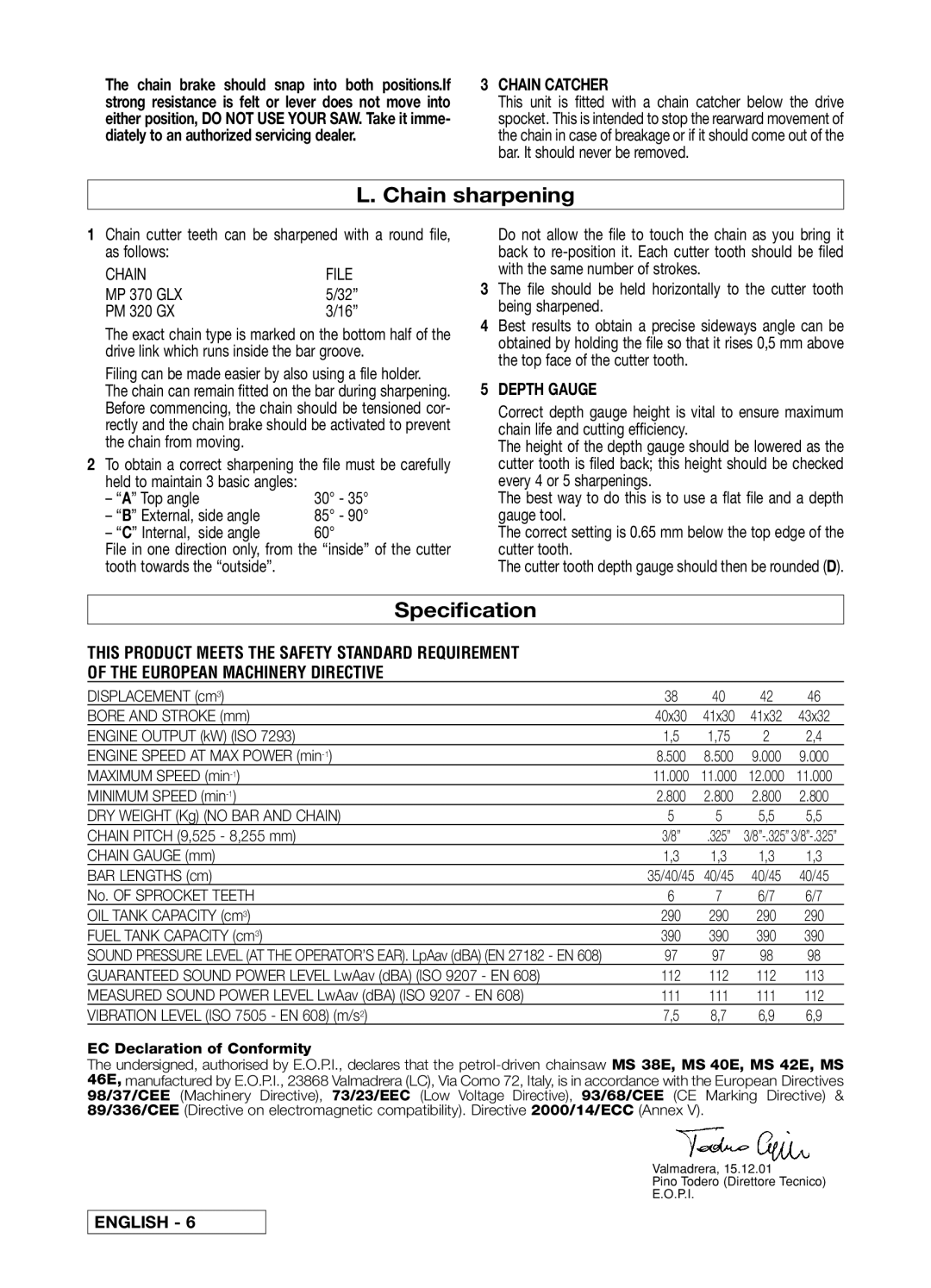

THIS PRODUCT MEETS THE SAFETY STANDARD REQUIREMENT

OF THE EUROPEAN MACHINERY DIRECTIVE

DISPLACEMENT (cm3) | 38 | 40 | 42 | 46 |

BORE AND STROKE (mm) | 40x30 | 41x30 | 41x32 | 43x32 |

ENGINE OUTPUT (kW) (ISO 7293) | 1,5 | 1,75 | 2 | 2,4 |

ENGINE SPEED AT MAX POWER | 8.500 | 8.500 | 9.000 | 9.000 |

MAXIMUM SPEED | 11.000 | 11.000 | 12.000 | 11.000 |

MINIMUM SPEED | 2.800 | 2.800 | 2.800 | 2.800 |

DRY WEIGHT (Kg) (NO BAR AND CHAIN) | 5 | 5 | 5,5 | 5,5 |

CHAIN PITCH (9,525 - 8,255 mm) | 3/8” | .325” | ||

CHAIN GAUGE (mm) | 1,3 | 1,3 | 1,3 | 1,3 |

BAR LENGTHS (cm) | 35/40/45 | 40/45 | 40/45 | 40/45 |

No. OF SPROCKET TEETH | 6 | 7 | 6/7 | 6/7 |

OIL TANK CAPACITY (cm3) | 290 | 290 | 290 | 290 |

FUEL TANK CAPACITY (cm3) | 390 | 390 | 390 | 390 |

SOUND PRESSURE LEVEL (AT THE OPERATOR’S EAR). LpAav (dBA) (EN 27182 - EN 608) | 97 | 97 | 98 | 98 |

GUARANTEED SOUND POWER LEVEL LwAav (dBA) (ISO 9207 - EN 608) | 112 | 112 | 112 | 113 |

MEASURED SOUND POWER LEVEL LwAav (dBA) (ISO 9207 - EN 608) | 111 | 111 | 111 | 112 |

VIBRATION LEVEL (ISO 7505 - EN 608) (m/s2) | 7,5 | 8,7 | 6,9 | 6,9 |

EC Declaration of Conformity

The undersigned, authorised by E.O.P.I., declares that the

Valmadrera, 15.12.01

Pino Todero (Direttore Tecnico)

E.O.P.I.