CONSTRUCTION

•Internal and external finishing in stainless steel 304 type.

•High density polyurethane insulation, 60 mm tickness, HCFC free.

•Environmentally friendly: R404a as refrigerant fluid.

•Developed and produced in ISO 9001 and ISO 14001 certified factory.

•Inner cell with fully rounded corners.

•Door equipped with removable magnetic gasket with hygienic design.

•Motors and fan waterproof protected IP20.

•Evaporator with antirust protection.

•Ventilator (fan) swinging hinged panel for access to the evaporator for cleaning.

Electrolux

Blast Chillers 180 kg - 20 GN 2/1

•Automatic heated door frame.

•Solenoid valves.

•1 thermostatic expansion valve.

•Stand alone printer as optional, built in on request.

•PC connection on request, gate RS 485.

INSTALLATION

•No water connections required.

•Waste water can be plumbed into drain, but can also be collected in an optional waste container.

*NF HYGIENE ALIMENTAIRE certifying authority : AFAQ AFNOR CERTIFICATION. Adress:11, Avenue Francis de Pressense - 93571

Installation diagram:

C - Water drain

I - Electrical connection

Y - Connection for appliance lifting L - Remote electrical connection N - Cooling water inlet

O - Cooling water outlet

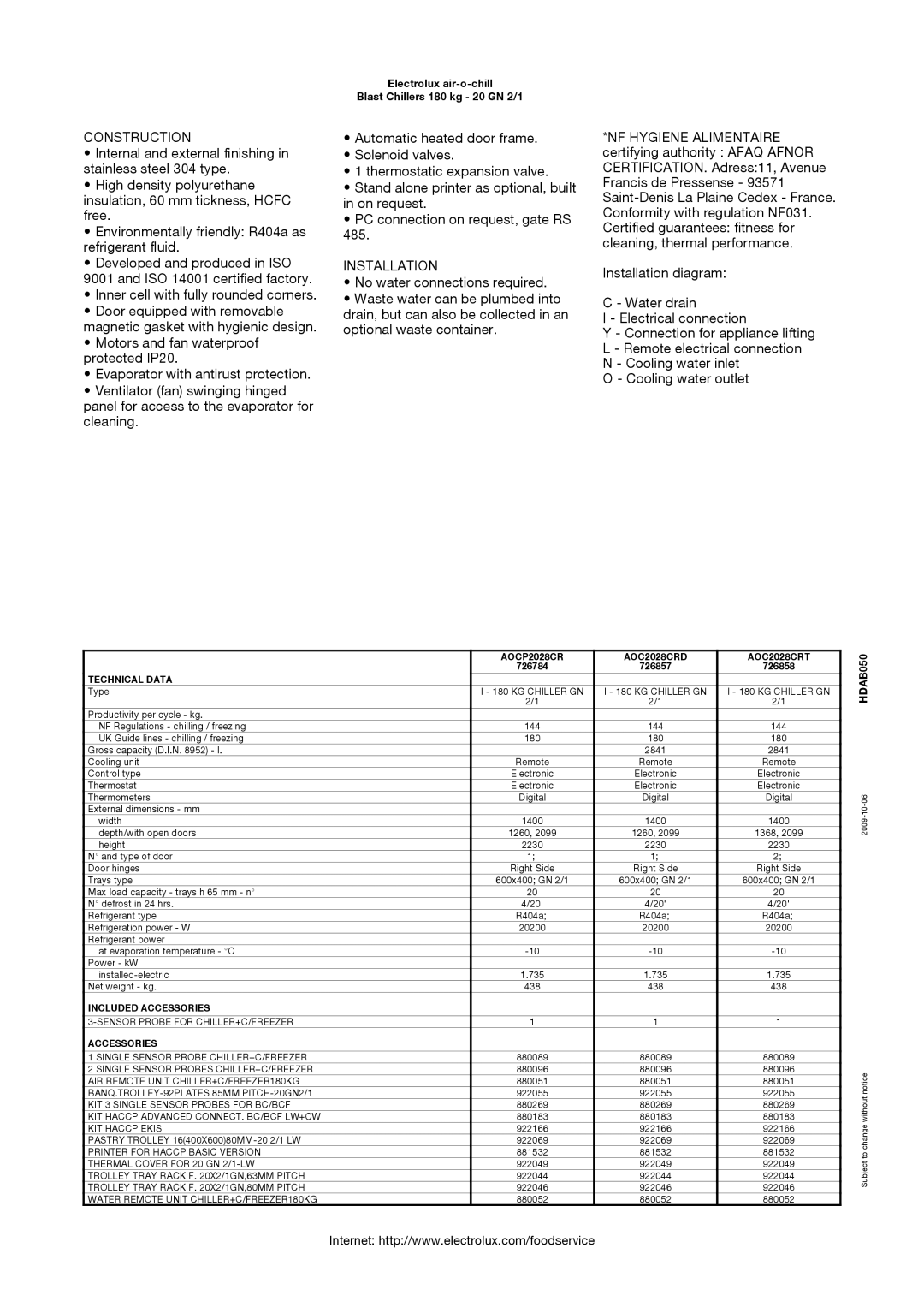

| AOCP2028CR | AOC2028CRD | AOC2028CRT | HDAB050 | |

| 726784 | 726857 | 726858 | ||

|

| ||||

TECHNICAL DATA |

|

|

|

| |

Type | I - 180 KG CHILLER GN | I - 180 KG CHILLER GN | I - 180 KG CHILLER GN |

| |

| 2/1 | 2/1 | 2/1 |

| |

Productivity per cycle - kg. |

|

|

|

| |

NF Regulations - chilling / freezing | 144 | 144 | 144 |

| |

UK Guide lines - chilling / freezing | 180 | 180 | 180 |

| |

Gross capacity (D.I.N. 8952) - l. |

| 2841 | 2841 |

| |

Cooling unit | Remote | Remote | Remote |

| |

Control type | Electronic | Electronic | Electronic |

| |

Thermostat | Electronic | Electronic | Electronic |

| |

Thermometers | Digital | Digital | Digital | 06 | |

External dimensions - mm |

|

|

| 10- | |

width | 1400 | 1400 | 1400 | - | |

2009 | |||||

depth/with open doors | 1260, 2099 | 1260, 2099 | 1368, 2099 | ||

| |||||

height | 2230 | 2230 | 2230 |

| |

N° and type of door | 1; | 1; | 2; |

| |

Door hinges | Right Side | Right Side | Right Side |

| |

Trays type | 600x400; GN 2/1 | 600x400; GN 2/1 | 600x400; GN 2/1 |

| |

Max load capacity - trays h 65 mm - n° | 20 | 20 | 20 |

| |

N° defrost in 24 hrs. | 4/20' | 4/20' | 4/20' |

| |

Refrigerant type | R404a; | R404a; | R404a; |

| |

Refrigeration power - W | 20200 | 20200 | 20200 |

| |

Refrigerant power |

|

|

|

| |

at evaporation temperature - °C |

| ||||

Power - kW |

|

|

|

| |

1.735 | 1.735 | 1.735 |

| ||

Net weight - kg. | 438 | 438 | 438 |

| |

INCLUDED ACCESSORIES |

|

|

|

| |

|

|

|

|

| |

1 | 1 | 1 |

| ||

ACCESSORIES |

|

|

|

| |

|

|

|

|

| |

1 SINGLE SENSOR PROBE CHILLER+C/FREEZER | 880089 | 880089 | 880089 |

| |

2 SINGLE SENSOR PROBES CHILLER+C/FREEZER | 880096 | 880096 | 880096 | notice | |

AIR REMOTE UNIT CHILLER+C/FREEZER180KG | 880051 | 880051 | 880051 | ||

| |||||

922055 | 922055 | 922055 | without | ||

KIT HACCP ADVANCED CONNECT. BC/BCF LW+CW | 880183 | 880183 | 880183 | ||

KIT 3 SINGLE SENSOR PROBES FOR BC/BCF | 880269 | 880269 | 880269 |

| |

|

|

|

| changeto | |

PRINTER FOR HACCP BASIC VERSION | 881532 | 881532 | 881532 | ||

KIT HACCP EKIS | 922166 | 922166 | 922166 |

| |

PASTRY TROLLEY | 922069 | 922069 | 922069 |

| |

|

|

|

|

| |

THERMAL COVER FOR 20 GN | 922049 | 922049 | 922049 | Subject | |

TROLLEY TRAY RACK F. 20X2/1GN,63MM PITCH | 922044 | 922044 | 922044 | ||

| |||||

TROLLEY TRAY RACK F. 20X2/1GN,80MM PITCH | 922046 | 922046 | 922046 |

| |

WATER REMOTE UNIT CHILLER+C/FREEZER180KG | 880052 | 880052 | 880052 |

|

Internet: http://www.electrolux.com/foodservice