If the door has to be opened from left to right, invert the position of the plates (7), the magnet (4) and the plate

(5)(Fig. B and E). Mount the countermagnet (6) and the hinges (1) as previously described.

|

|

| E |

4 |

|

| 6 |

|

|

| |

| 5 | 7 | 1 |

|

| ||

|

|

| |

|

|

| 3 |

P0983 |

|

| 2 |

|

|

|

Recommendations regarding the construction and fitting of a base when the installation requires an integrated appliance to be raised

Where the appliance has been raised by mounting onto a wooden base provided by the installer. The material used to construct the base should have a non slip surface, be water repellent and if possible be one solid piece.

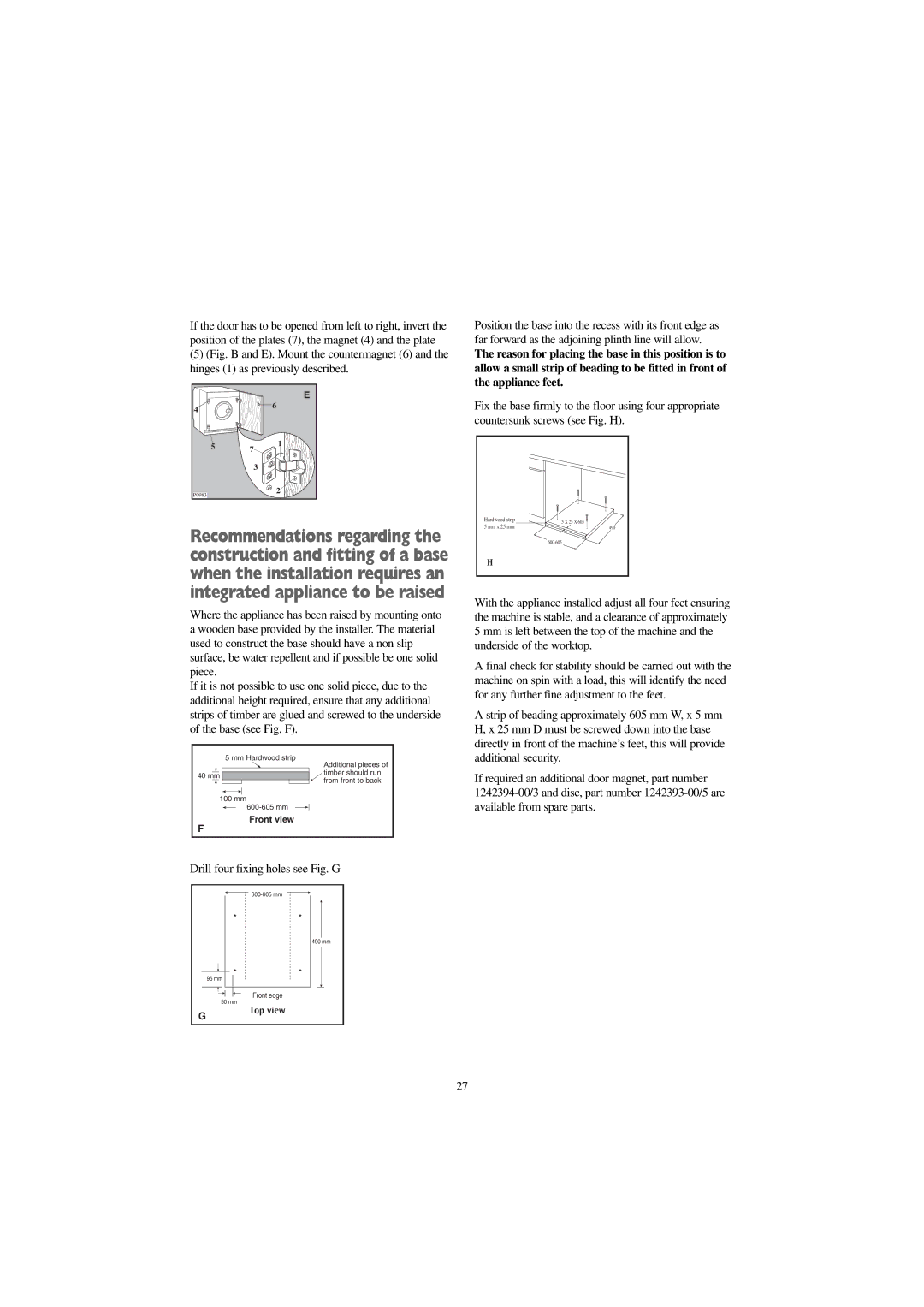

If it is not possible to use one solid piece, due to the additional height required, ensure that any additional strips of timber are glued and screwed to the underside of the base (see Fig. F).

Position the base into the recess with its front edge as far forward as the adjoining plinth line will allow.

The reason for placing the base in this position is to allow a small strip of beading to be fitted in front of the appliance feet.

Fix the base firmly to the floor using four appropriate countersunk screws (see Fig. H).

Hardwood strip | 5 X 25 X 605 | |

5 mm x 25 mm | ||

490 | ||

|

H

With the appliance installed adjust all four feet ensuring the machine is stable, and a clearance of approximately 5 mm is left between the top of the machine and the underside of the worktop.

A final check for stability should be carried out with the machine on spin with a load, this will identify the need for any further fine adjustment to the feet.

A strip of beading approximately 605 mm W, x 5 mm H, x 25 mm D must be screwed down into the base directly in front of the machine’s feet, this will provide

5mm Hardwood strip

40 mm ![]()

![]()

![]()

100 mm

Additional pieces of timber should run from front to back

additional security.

If required an additional door magnet, part number

F

Front view

Drill four fixing holes see Fig. G

| |

| 490 mm |

| 95 mm |

| Front edge |

| 50 mm |

G | Top view |

|

27