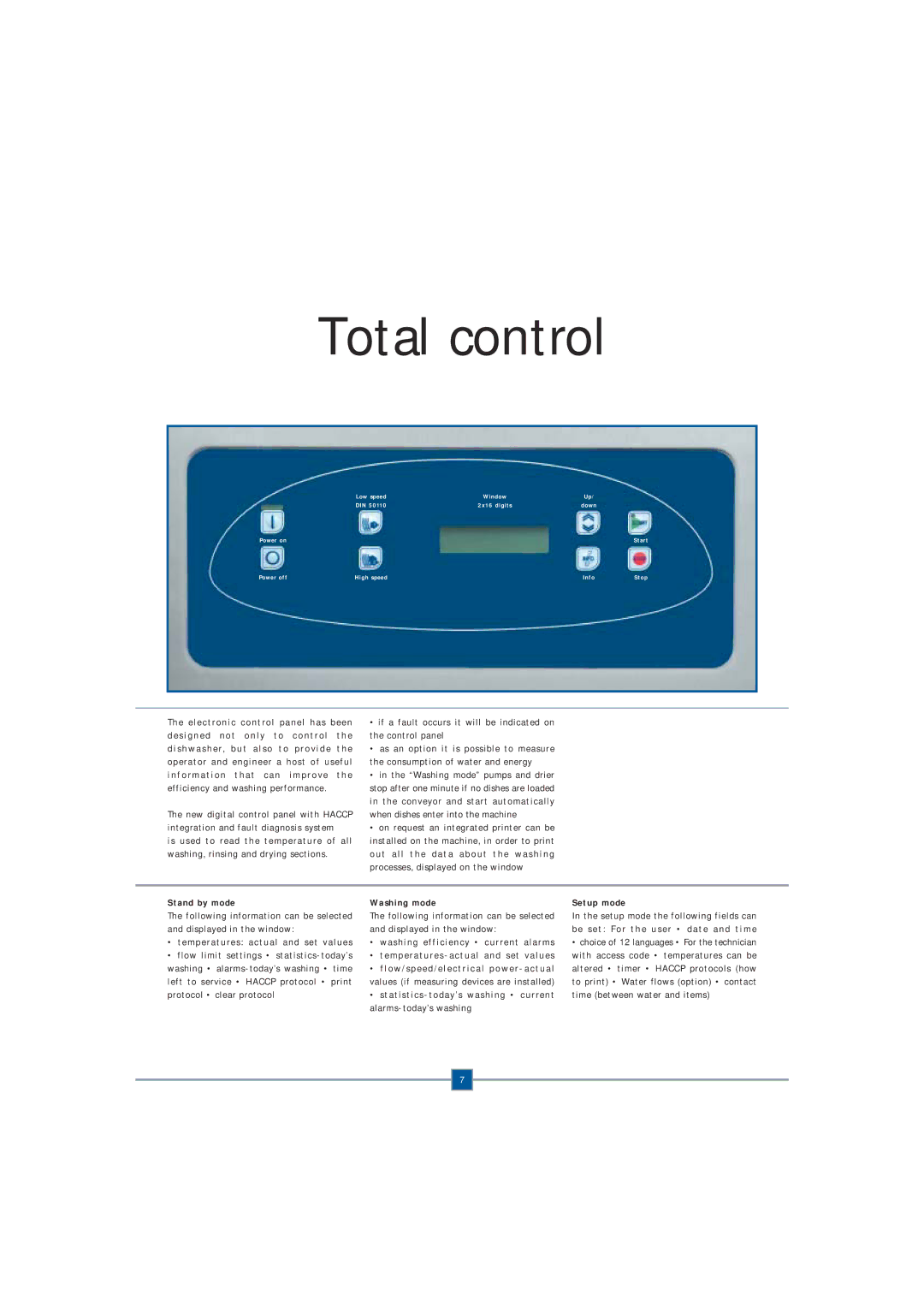

Total control

| Low speed | Window | Up/ |

|

| DIN 50110 | 2x16 digits | down |

|

Power on |

|

|

| Start |

Power off | High speed |

| Info | Stop |

The electronic control panel has been d e s i g n e d n o t o n l y t o c o n t r o l t h e d i s h w a s h e r, b u t a l s o t o p r o v i d e t h e operator and engineer a host of useful i n f o r m a t i o n t h a t c a n i m p r o v e t h e efficiency and washing performance.

The new digital control panel with HACCP integration and fault diagnosis system

is used to read the temperature of all washing, rinsing and drying sections.

•if a fault occurs it will be indicated on the control panel

•as an option it is possible to measure the consumption of water and energy

•in the “Washing mode” pumps and drier stop after one minute if no dishes are loaded in the conveyor and start automatically when dishes enter into the machine

•on request an integrated printer can be installed on the machine, in order to print

o u t a l l t h e d a t a a b o u t t h e w a s h i n g processes, displayed on the window

Stand by mode | Washing mode |

| Setup mode |

The following information can be selected | The following information can be selected | In the setup mode the following fields can | |

and displayed in the window: | and displayed in the window: | b e s e t : F o r t h e u s e r • d a t e a n d t i m e | |

• temperatures: actual and set values | • washing efficiency • current alarms | • choice of 12 languages • For the technician | |

• flow limit settings • | • t e m p e r a t u r e s - a c t u a l | a n d s e t v a l u e s | with access code • temperatures can be |

washing • | • f l o w / s p e e d / e l e c t r i c a l | p o w e r - a c t u a l | altered • timer • HACCP protocols (how |

left to service • HACCP protocol • print | values (if measuring devices are installed) | to print) • Water flows (option) • contact | |

protocol • clear protocol | • statistics - today’s washing • current | time (between water and items) | |

|

|

| |

7