Installation Instructions

Refrigeration Packages

INSTALLATION

1.Insure proper ventilation. In fully recessed drinking fountains be sure condenser faces louver panel and is within 1/2" (13 mm) of louver panel when panel is in place.

2.Water inlet is 3/8" (10 mm) O.D. unplated tube . Contractor to supply connections as required.

3.Connecting lines to be made of unplated copper. Thoroughly flush all lines to remove all foreign matter before connecting to cooler.

4.Connect cooler to building supply with a

NOTE: DO NOT SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE

5.Electrical: Make sure power supply is identical in voltage, cycle, and phase to that specified on cooler serial plate. Never wire the compressor directly to the power supply.

IMPORTANT! INSTALLER PLEASE NOTE:

The grounding of electrical equipment such as telephone, computers, etc., to water lines is a common procedure. This grounding may be in the building, or may occur away from the building. This grounding can cause electrical feedback into a water chiller, creating an electrolysis which causes a metallic taste or an increase in the metal content of the water. This condition is avoidable by using the proper materials indicated below. Drain fittings which are provided by the installer should be plastic to electrically isolate the chiller from the building plumbing system.

START-UP

1.Open supply line valve.

2.Purge all air from all water lines by operating bubbler valve of fountain to which cooler is connected. A steady stream flow assures that all air is removed.

3.Rotate fan blade to assure proper clearance and free action.

4.Connect to proper electrical power.

TROUBLE SHOOTING & MAINTENANCE

Temperature Control:

Ventilation: Cabinet louvers and condenser fins should be periodically cleaned with a brush, air hose, or vacuum cleaner. Excess dirt or poor ventilation can cause no cold water and compressor cycling on the overload protector.

Lubrication: Motors are lifetime lubricated.

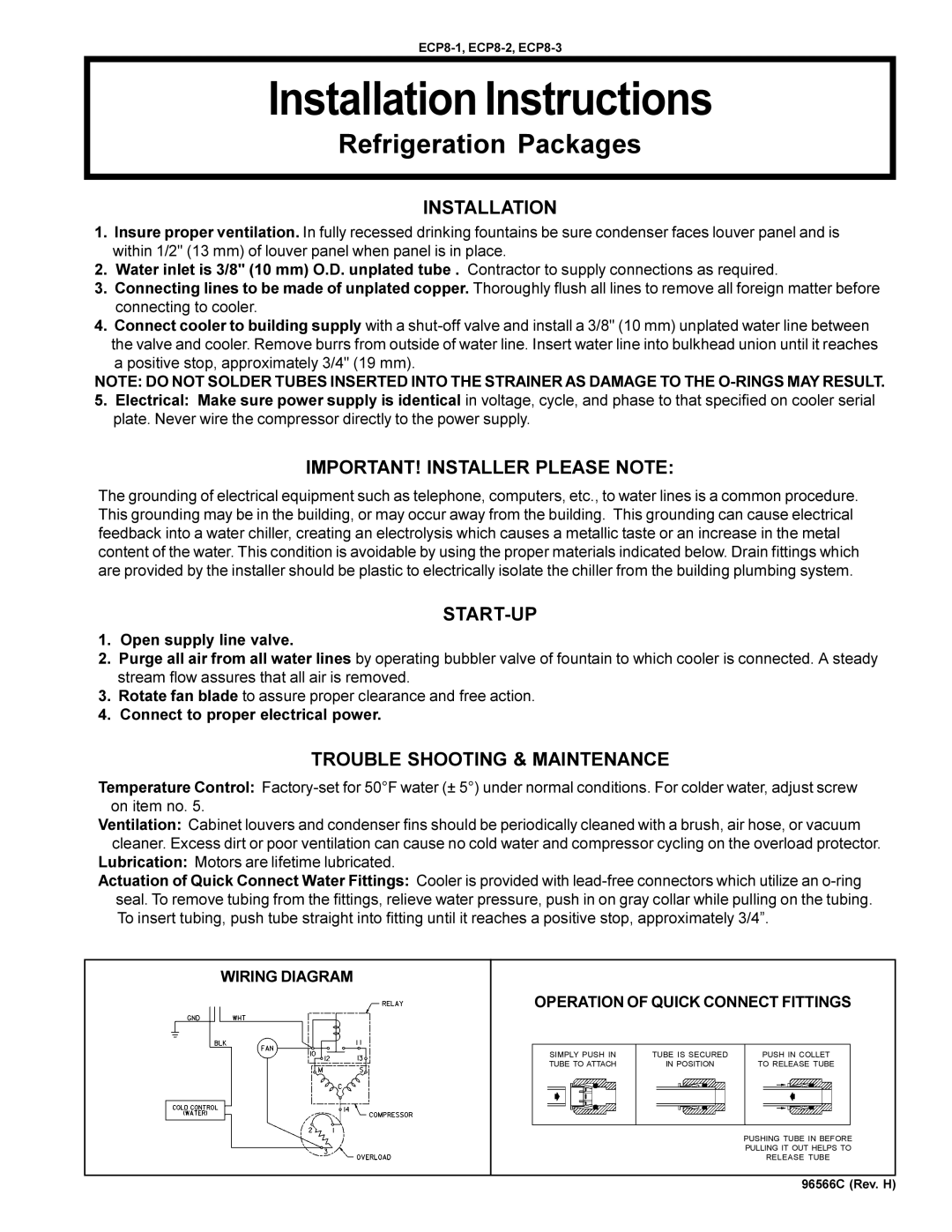

Actuation of Quick Connect Water Fittings: Cooler is provided with

WIRING DIAGRAM |

|

|

|

| OPERATION OF QUICK CONNECT FITTINGS | ||

| SIMPLY PUSH IN | TUBE IS SECURED | PUSH IN COLLET |

| TUBE TO ATTACH | IN POSITION | TO RELEASE TUBE |

|

|

| PUSHING TUBE IN BEFORE |

|

|

| PULLING IT OUT HELPS TO |

|

|

| RELEASE TUBE |

|

|

|

|

96566C (Rev. H)