WEB/485 specifications

The Emerson WEB/485 is a powerful and versatile web-server designed for the continuous monitoring and management of industrial automation systems. As a robust device, it facilitates communication between various field devices, such as sensors, controllers, and data acquisition systems, and provides users with remote access to these systems through standard web protocols.One of the standout features of the WEB/485 is its capability to support multiple communication protocols. It is compatible with MODBUS RTU, MODBUS TCP/IP, and several others, making it an ideal solution for integrating legacy systems with modern technologies. This flexibility allows users to harness the full potential of their existing infrastructure without the need for costly and extensive upgrades.

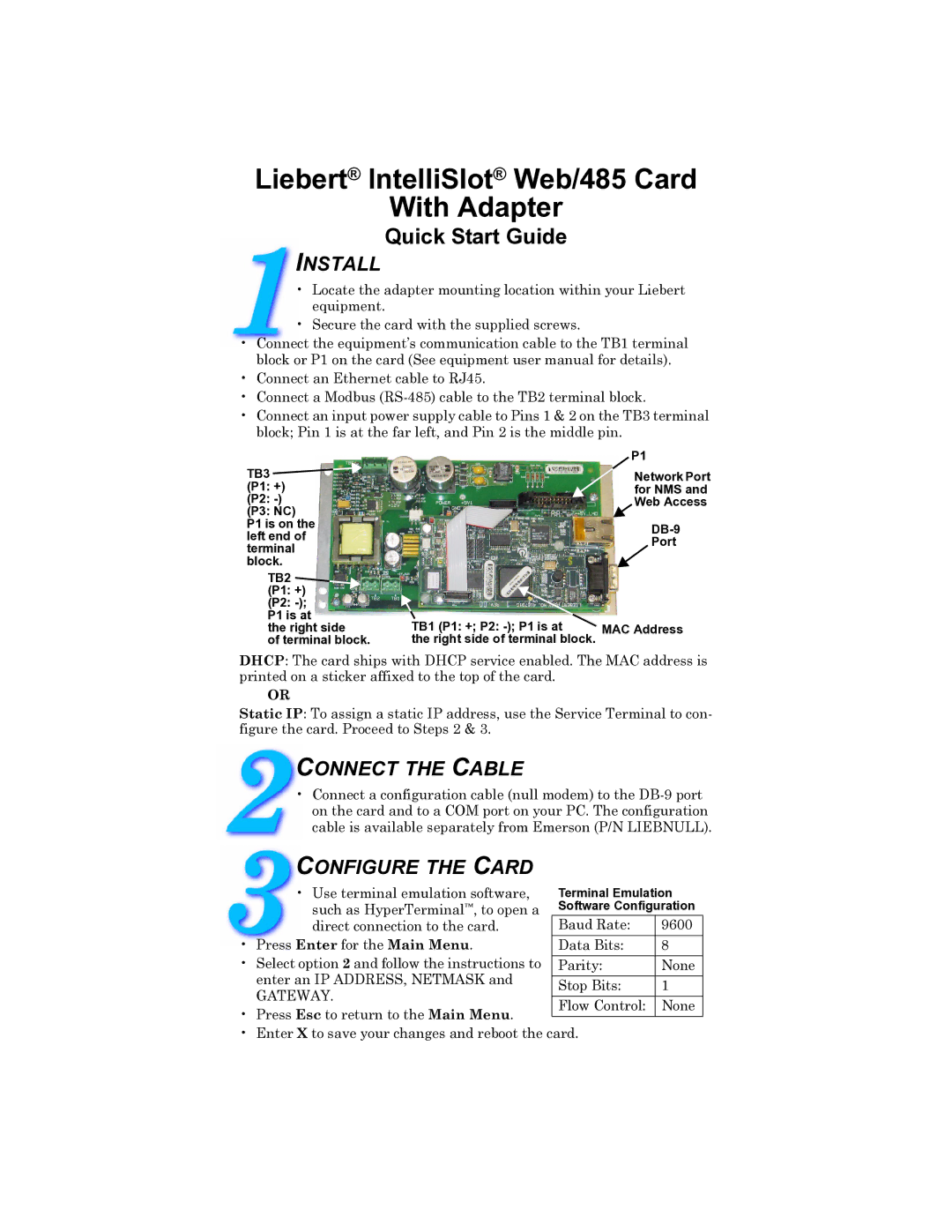

The WEB/485 is equipped with an Ethernet port along with RS-232/RS-485 serial interfaces, enabling reliable data transmission over both wired networks and point-to-point connections. The dual communication interfaces enhance the device’s adaptability, allowing it to serve diverse environments—from factory floors to remote monitoring stations.

Security is a top priority for industrial applications, and the WEB/485 addresses this with built-in features such as user authentication and encrypted communications. This ensures that sensitive data remains secure and minimizes the risk of unauthorized access to the automation system.

Another notable characteristic of the Emerson WEB/485 is its user-friendly web interface. The device’s graphical user interface (GUI) allows operators to easily visualize real-time data, configure system settings, and generate reports without extensive training or specialized knowledge. This ease of use helps businesses improve operational efficiency as personnel can quickly respond to system alerts and anomalies.

In addition to its standard features, the WEB/485 supports customizable data logging and alarm management. Users can set up thresholds for various parameters and receive notifications via email or SMS when certain criteria are met, enabling proactive maintenance and reducing downtime.

Overall, the Emerson WEB/485 combines robust communication capabilities, security features, and user-friendly design, making it an essential tool for modern industrial automation. Its integration capabilities allow for seamless operation within a variety of systems, ultimately contributing to enhanced productivity and reliability in complex industrial environments. With its advanced functionalities, it stands out as a preferred choice for engineers and technicians aiming to optimize their automation processes.